Abstract

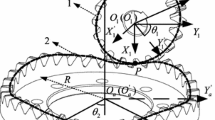

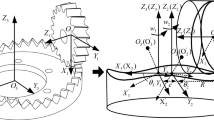

In order to improve the meshing performance of non-orthogonal helical face-gears, a designation of double-crowned tooth modification with high-order transmission error (HTE) is constructed in this paper. First, the double-crowned tooth modification is designed based on the tooth profile modification of the rack-cutter and the motion relationship between the rack-cutter and the processed pinion, and then, the designation of high-order tooth modification is verified by using tooth contact analysis (TCA). Second, a parameterized 3D grid of modified gears is generated based on MATLAB programming, and a simulation of loaded tooth contact analysis for modified non-orthogonal helical face-gears is carried out by using ABAQUS software. Third, the calculation results of the standard tooth, second-order parabolic modified tooth and high-order parabolic modified tooth are compared with and without the assembly errors. Ultimately, an example is presented and the results show that the geometric transmission error of the newly designed high-order modified non-orthogonal helical face-gears conforms to the expected design. Compared with the second-order parabolic tooth modification, the newly designed high-order tooth modification pair shows a better meshing performance with and without assembly errors. The research of this paper can provide ideas and methods for the tooth modification design of non-orthogonal helical face-gear.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Litvin FL, Zhang Y, Wang JC et al (1992) Design and geometry of face-gear drives. J Mech Des 114(4):642–647

Feng G, Xie Z, Zhou M (2019) Geometric design and analysis of face-gear drive with involute helical pinion. Mech Mach Theory 134:169–196

Guan Y, Fa Ng Z, Yang X et al (2018) Tooth contact analysis of crown gear coupling with misalignment. Mech Mach Theory 126:295–311

Liu S, Song C, Zhu C et al (2018) Concave and convex modifications analysis for skewed beveloid gears considering misalignments. Mech Mach Theory 133

Deng J, Nie S, Deng X et al (2020) Tooth surface mismatch modification method of cycloidal bevel gear based on conjugate tooth surface modification. J Adv Mech Des Syst Manuf 14(1):1–22

Huang KJ, Su CY (2013) A finite element approach to dynamic stresses of helical gear pairs considering tip relief and crowning modifications. Appl Mech Mater 284–287:577–581

Sun Z, Chen S, Hu Z et al (2022) Improved mesh stiffness calculation model of comprehensive modification gears considering actual manufacturing. Mech Mach Theory 167:104470

Zanzi C, Pedrero JI (2005) Application of modified geometry of face gear drive. Comput Methods Appl Mech Eng 194(27):3047–3066

Tran VQ, Wu YR (2019) A novel method for closed-loop topology modification of helical gears using internal-meshing gear honing. Mech Mach Theory 145:103691

Li T, An X, Deng X, Li J, Li Y (2020) A new tooth profile modification method of cycloidal gears in precision reducers for robots. Appl Sci 10(4):1266

Litvin FL, Jian L, Townsend DP et al (1997) Computerized simulation of meshing of conventional helical involute gears and modification of geometry. Mech Mach Theory 34(1):123–147

Zschippang HA, Weikert S, KüüK K et al (2019) Face-gear drive: geometry generation and tooth contact analysis. Mech Mach Theory 142:103576

Dongsheng H (2012) Research on numerical analysis modeling method for gear meshing and its applications. Dalian University of Technology (in Chinese)

Jiang J, Fang Z (2015) Design and analysis of modified cylindrical gears with a higher-order transmission error. Mech Mach Theory 88

Jia C, Fang Z (2019) Design and analysis of double-crowned high-contact-ratio cylindrical gears considering the load sharing of the multi-pair contact. Mech Mach Theory 131:92–114

Su J, Fang Z, Cai X (2013) Design and analysis of spiral bevel gears with seventh-order function of transmission error. Chin J Aeronaut 26(5):1310–1316

Mu Y, Li W, Fang Z et al (2018) A novel tooth surface modification method for spiral bevel gears with higher-order transmission error. Mech Mach Theory 126:49–60

Yunbo S (2013) Novel design process for face gear drive with a high order polynomial function of transmission error. J Xi’an Technol Univ 33(12):7 (in Chinese)

Daqing L, Suzhen W, Rangqian Z et al (2020) Design of the high-order curve tooth profile and analysis on the face gear’s tooth contact. J Mach Des 37(11):109–114 (in Chinese)

Ning Z, Xiaochun Z, Hui G et al (2008) Tooth contact analysis of face gear drive with helical pinion and simulation of the tooth face. J Aerosp Power 23(10):1927–1932 (in Chinese)

Jacquin V (2005) Quasi-static analysis of a face gear under torque. Comput Methods Appl Mech Eng 194:4301–4318

Vouaillat G, Noyel JP, Ville F et al (2019) From Hertzian contact to spur gears: analyses of stresses and rolling contact fatigue. Mech Ind 20(6):1–16

Wang H, Tang L, Zhou C et al (2021) Wear life prediction method of crowned double helical gear drive in point contact mixed elastohydrodynamic lubrication. Wear 484–485:204041

Litvin FL, Fuentes A, Zanzi C et al (2002) Face-gear drive with spur involute pinion: geometry, generation by a worm, stress analysis. Comput Methods Appl Mech Eng 191(25–26):2785–2813

Xuezhong F, Zongde F, Long X et al (2018) Assembly errors tolerance and sensitivity of offset face gears. J Harbin Eng Univ 39(7):1227–1232 (in Chinese)

Xianlong P, QichaoI X, Xiangying H et al (2020) Finite element analysis of gear bearing transmission performance influenced by misalignment. J Harbin Eng Univ 41(12):1861–1867 (in Chinese)

Acknowledgements

Supported by National Natural Science Foundation of China (Project No.52005107), and the Natural Science Foundation of Fujian Province, China (Project No. 2020J05100).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Xu, J., Jia, C. (2023). Design and Analysis of Modified Non-orthogonal Helical Face-Gears with a High-Order Transmission Error. In: Liu, X. (eds) Advances in Mechanism, Machine Science and Engineering in China. CCMMS 2022. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-9398-5_13

Download citation

DOI: https://doi.org/10.1007/978-981-19-9398-5_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-9397-8

Online ISBN: 978-981-19-9398-5

eBook Packages: EngineeringEngineering (R0)