Abstract

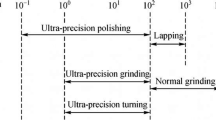

Single-point diamond turning (SPDT) is an ultra-precision subtractive material removal process to achieve optical-finish surfaces almost on any material. Due to this capability to produce nano-level surface finish, it has become an important advanced manufacturing process for optics, semiconductors, biomedical, defense and aerospace sectors. However, due to its initial setup cost, its popularity and uses have been suppressed in many regions. As it is a nanoscale regime machining process, size effect has a major influence along with effective rake angle, tool wear, crystallographic orientation, ploughing, rubbing, burnishing, build-up edge, tool vibration, material swelling and elastic recovery. All these factors need to be studied to understand in order to improve the outcome of the process. Numerical simulation is one of the low-cost alternative methods to study the process and its influencing factors on product quality and process efficiency. These techniques can provide insight into the effects of cutting process that are often difficult see through physical experiments. Studies showed that the methods helped the researchers in understanding the insight of process, physics and origins of chip formations, microstructural behaviour during plastic deformation. Thus, it is ascertained that these alternatives methods if effectively designed may help to cut down the (a) operating and metrological cost and time, (b) predict the outcome of the processes and (c) optimize the process parameters without carrying out costly and tiresome experiments. The approach is found to be simple and economical and a possible substitute for costly, tedious and time-consuming physical experiments.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Davis GE, Roblee JW, Hedges AR (2009) Comparison of freeform manufacturing techniques in the production of monolithic lens arrays. In: Optical manufacturing and testing VIII (vol 7426). International Society for Optics and Photonics, p 742605

Davies MA, Evans CJ, Vohra RR, Bergner BC, Patterson SR (2003) Application of precision diamond machining to the manufacture of microphotonics components. In: Lithographic and micromachining techniques for optical component fabrication II (vol 5183). International Society for Optics and Photonics, pp 94–109

Ikawa N, Donaldson RR, Komanduri R, König W, McKeown PA, Moriwaki T, Stowers IF (1991) Ultraprecision metal cutting—the past, the present and the future. CIRP Ann Manuf Technol 40(2):587–594

Yu DP, San Wong Y, Hong GS (2011) A novel method for determination of the subsurface damage depth in diamond turning of brittle materials. Int J Mach Tools Manuf 51(12):918–927

Sumipro, https://www.sumipro.nl/technicaloptics/. Last Accessed on 12 June 2018

Chiu WM, Lee WB (1997) Development of ultra-precision machining technology

Goel S (2013) An atomistic investigation on the nanometric cutting mechanism of hard, brittle materials. Doctoral dissertation, Heriot-Watt University

Optics & Allied Engineering Pvt. Ltd., http://www.opticsindia.com/products/ir-optics-and-spdt/spdt-applications-areas/. Last Accessed on 10 Jan 2019

Fang FZ, Zhang XD, Weckenmann A, Zhang GX, Evans C (2013) Manufacturing and measurement of freeform optics. CIRP Ann 62(2):823–846

Krauskopf B (1984) Diamond turning: reflecting demands for precision. Manuf Eng 92(5):90–100

King RF, Tabor D (1954) The strength properties and frictional behaviour of brittle solids. Proc R Soc Lond A 223(1153):225–238

Leung TP, Lee WB, Lu XM (1998) Diamond turning of silicon substrates in ductile-regime. J Mater Process Technol 73(1–3):42–48

Patten JA, Gao W (2001) Extreme negative rake angle technique for single point diamond nano-cutting of silicon. Precis Eng 25(2):165–167

Yan J, Yoshino M, Kuriagawa T, Shirakashi T, Syoji K, Komanduri R (2001) On the ductile machining of silicon for micro electro-mechanical systems (MEMS), opto-electronic and optical applications. Mater Sci Eng, A 297(1–2):230–234

Yoshino M, Aoki T, Shirakashi T, Komanduri R (2001) Some experiments on the scratching of silicon: In situ scratching inside an SEM and scratching under high external hydrostatic pressures. Int J Mech Sci 43(2):335–347

Kong MC, Lee WB, Cheung CF, To S (2006) A study of materials swelling and recovery in single-point diamond turning of ductile materials. J Mater Process Technol 180(1–3):210–215

Mishra V, Garg H, Karar V, Khan GS (2019) Ultra-precision diamond turning process. In: Micro and nano machining of engineering materials. Springer, Cham, pp 65–97

Ding X, Rahman M (2012) A study of the performance of cutting polycrystalline Al 6061 T6 with single crystalline diamond micro-tools. Precis Eng 36(4):593–603

Kushendarsyah S, Sathyan S (2013) Orthogonal microcutting of thin workpieces. J Manuf Sci Eng 135(3):031004

Fang FZ, Huang KT, Gong H, Li ZJ (2014) Study on the optical reflection characteristics of surface micro-morphology generated by ultra-precision diamond turning. Opt Lasers Eng 62:46–56

Luo X, Tong Z, Liang Y (2014) Investigation of the shape transferability of nanoscale multi-tip diamond tools in the diamond turning of nanostructures. Appl Surf Sci 321:495–502

Mahajan KA, Sadaiah M, Gawande SH (2010) Experimental investigations of surface roughness on OFHC copper by diamond turning machine. Int J Eng Sci Technol 2(10):5215–5220

Zong WJ, Huang YH, Zhang YL, Sun T (2014) Conservation law of surface roughness in single point diamond turning. Int J Mach Tools Manuf 84:58–63

Zhou M, Zhang HJ, Chen SJ (2010) Study on diamond cutting of nonrationally symmetric microstructured surfaces with fast tool servo. Mater Manuf Process 25(6):488–494

Lin ZC, Huang JC, Jeng YR (2007) 3D nano-scale cutting model for nickel material. J Mater Process Technol 192:27–36

Wang H, To S (2011) A study on tool wear in ultra-precision diamond turning with finite element modelling. Int J Nanomanuf 7(5–6):500–516

Yu DP, Hong GS, San Wong Y (2012) Profile error compensation in fast tool servo diamond turning of micro-structured surfaces. Int J Mach Tools Manuf 52(1):13–23

Fang FZ (1998) Nano-turning of single crystal silicon. J Mater Process Technol 82(1–3):95–101

Yan J, Syoji K, Tamaki JI (2003) Some observations on the wear of diamond tools in ultra-precision cutting of single-crystal silicon. Wear 255(7–12):1380–1387

Fang FZ, Wu H, Zhou W, Hu XT (2007) A study on mechanism of nano-cutting single crystal silicon. J Mater Process Technol 184(1–3):407–410

Goel S, Luo X, Reuben RL (2013) Wear mechanism of diamond tools against single crystal silicon in single point diamond turning process. Tribol Int 57:272–281

Singh K, Vaishya RO, Singh H, Mishra V, Ramagopal S (2013) Investigation of tool life and surface roughness during single point diamond turning of silicon. Int J Sci Res 2(6):265–267

Patten J, Gao W, Yasuto K (2005) Ductile regime nanomachining of single-crystal silicon carbide. J Manuf Sci Eng 127(3):522–532

Patten JA, Jacob J (2008) Comparison between numerical simulations and experiments for single-point diamond turning of single-crystal silicon carbide. J Manuf Process 10(1):28–33

Ravindra D, Patten JA, Qu J (2009) Single point diamond turning effects on surface quality and subsurface damage in ceramics. In ASME 2009 international manufacturing science and engineering conference. American Society of Mechanical Engineers, pp 707–713

Luo X, Goel S, Reuben RL (2012) A quantitative assessment of nanometric machinability of major polytypes of single crystal silicon carbide. J Eur Ceram Soc 32(12):3423–3434

Goel S, Luo X, Comley P, Reuben RL, Cox A (2013) Brittle–ductile transition during diamond turning of single crystal silicon carbide. Int J Mach Tools Manuf 65:15–21

Goel S, Stukowski A, Luo X, Agrawal A, Reuben RL (2013) Anisotropy of single-crystal 3C–SiC during nanometric cutting. Modell Simul Mater Sci Eng 21(6):065004

Blackley WS, Scattergood RO (1989) Diamond turning of brittle materials. 5th Int Precision Eng Seminar 18(22):9

Patten JA (1996) High pressure phase transformation analysis and molecular dynamics simulations of single point diamond turning of Germanium

Yan J, Takahashi Y, TAMAKI JI, Kubo A, Kuriyagawa T, Sato Y (2006) Ultraprecision machining characteristics of poly-crystalline germanium. JSME Int J Series C Mech Syst, Mach Elements Manuf 49(1):63–69

Pawase P, Brahmankar PK, Pawade RS, Balasubramanium R (2014) Analysis of machining mechanism in diamond turning of germanium lenses. Procedia Mater Sci 5:2363–2368

Gupta S, Khatri N, Karar V, Dhami SS (2016) Investigation of surface roughness of single point diamond turned germanium substrate by coherence correlation interferometry and image processing. In: IOP conference series: materials science and engineering (vol 149, No 1). IOP Publishing, p 012032

Fang FZ, Liu XD, Lee LC (2003) Micro-machining of optical glasses—a review of diamond-cutting glasses. Sadhana 28(5):945–955

Fang FZ, Zhang GX (2004) An experimental study of optical glass machining. Int J Adv Manuf Technol 23(3–4):155–160

Bhagwat Vishal B, Manu R, Sreenath AM (2012) Ductile mode machining simulation of glass material using MATLAB. 2(4)

Bifano TG, Dow TA, Scattergood RO (1991) Ductile-regime grinding: a new technology for machining brittle materials. J Eng Ind 113(2):184–189

Anand PSP (2019) Significance of diamond as a cutting tool in ultra-precision machining process. In: Some aspects of diamonds in scientific research and high technology. IntechOpen

Lawn BR, Wilshaw R (1975) Indentation fracture: principles and applications. J Mater Sci 10(6):1049–1081

Lawn BR, Evans AG (1977) A model for crack initiation in elastic/plastic indentation fields. J Mater Sci 12(11):2195–2199

Lawn BR, Evans AG, Marshall DB (1980) Elastic/plastic indentation damage in ceramics: the median/radial crack system. J Am Ceram Soc 63(9–10):574–581

Marshall DB, Lawn BR (1985) Indentation of brittle materials. In: Microindentation techniques in materials science and engineering. ASTM International

Toh SB, McPherson R (1986) Fine scale abrasive wear of ceramics by a plastic cutting process. In: Almond EA, Brookes CA, Warren R (eds) Science of hard materials. Proceedings of 2nd international conference on science of hard materials held at rhodes 23–28 Sept 1984. Adam Hilger, Bristol, p 865

Moriwaki T, Shamoto E, Inoue K (1992) Ultraprecision ductile cutting of glass by applying ultrasonic vibration. CIRP Ann 41(1):141–144

Blackley WS, Scattergood RO (1994) Chip topography for ductile-regime machining of germanium. J Eng Ind 116(2):263–266

Fang FZ, Venkatesh VC (1998) Diamond cutting of silicon with nanometric finish. CIRP Ann 47(1):45–49

Huerta M, Malkin S (1976) Grinding of glass: the mechanics of the process. J Eng Ind 98(2):459–467

Moore MA, King FS (1980) Abrasive wear of brittle solids. Wear 60(1):123–140

Blake PN, Scattergood RO (1989) Ductile-regime turning of germanium and silicon

Blake PN, Scattergood RO (1990) Ductile-regime machining of germanium and silicon. J Am Ceram Soc 73(4):949–957

Yan J, Takahashi H, Gai X, Harada H, Tamaki JI, Kuriyagawa T (2006) Load effects on the phase transformation of single-crystal silicon during nanoindentation tests. Mater Sci Eng, A 423(1–2):19–23

Rao R, Bradby JE, Ruffell S, Williams JS (2007) Nanoindentation-induced phase transformation in crystalline silicon and relaxed amorphous silicon. Microelectron J 38(6–7):722–726

Goel S, Faisal NH, Luo X, Yan J, Agrawal A (2014) Nanoindentation of polysilicon and single crystal silicon: molecular dynamics simulation and experimental validation. J Phys D Appl Phys 47(27):275304

Goel S, Yan J, Luo X, Agrawal A (2014) Incipient plasticity in 4H–SiC during quasistatic nanoindentation. J Mech Behav Biomed Mater 34:330–337

Meng B, Zhang F, Li Z (2015) Deformation and removal characteristics in nanoscratching of 6H-SiC with Berkovich indenter. Mater Sci Semicond Process 31:160–165

Arif M, Xinquan Z, Rahman M, Kumar S (2013) A predictive model of the critical undeformed chip thickness for ductile–brittle transition in nano-machining of brittle materials. Int J Mach Tools Manuf 64:114–122

Xiao G, Ren M, To S (2018) A study of mechanics in brittle-ductile cutting mode transition. Micromachines 9(2):49

Yan J, Asami T, Harada H, Kuriyagawa T (2012) Crystallographic effect on subsurface damage formation in silicon microcutting. CIRP Ann Manuf Technol 61(1):131–134

Fang FZ, Zhang GX (2003) An experimental study of edge radius effect on cutting single crystal silicon. Int J Adv Manuf Technol 22(9–10):703–707

Wu H, Melkote SN (2012) Study of ductile-to-brittle transition in single grit diamond scribing of silicon: application to wire sawing of silicon wafers. J Eng Mater Technol 134(4)

Yin L, Vancoille EYJ, Lee LC, Liu YC, Huang H, Ramesh K (2003) High-precision low-damage grinding of polycrystalline SiC. In: Key engineering materials (vol 238). Trans Tech Publications, pp 59–64

Yuan YC, Li BZ, Zhou ZX, Zhang Q (2012) Study on the simulation model and characteristics of high-speed grinding for ceramics. In: Applied mechanics and materials (vol 138). Trans Tech Publications, pp 662–667

Zhu D, Yan S, Li B (2014) Single-grit modeling and simulation of crack initiation and propagation in SiC grinding using maximum undeformed chip thickness. Comput Mater Sci 92:13–21

Beltrão PA, Gee AE, Corbett J, Whatmore RW, Goat CA, Impey SA (1999) Single point diamond machining of ferroelectric materials. J Eur Ceram Soc 19(6–7):1325–1328

Ngoi BKA, Sreejith PS (2000) Ductile regime finish machining-a review. Int J Adv Manuf Technol 16(8):547–550

Yan J, Asami T, Harada H, Kuriyagawa T (2009) Fundamental investigation of subsurface damage in single crystalline silicon caused by diamond machining. Precis Eng 33(4):378–386

Yan J, Zhao H, Kuriyagawa T (2009) Effects of tool edge radius on ductile machining of silicon: an investigation by FEM. Semicond Sci Technol 24(7):075018

Lawn BR, Padture NP, Cait H, Guiberteau F (1994) Making ceramics “ductile.” Science 263(5150):1114–1116

Nakasuji T, Kodera S, Hara S, Matsunaga H, Ikawa N, Shimada S (1990) Diamond turning of brittle materials for optical components. CIRP Ann Manuf Technol 39(1):89–92

Bridgman PW, Šimon I (1953) Effects of very high pressures on glass. J Appl Phys 24(4):405–413

Morris JC, Callahan DL, Kulik J, Patten JA, Scattergood RO (1995) Origins of the ductile regime in single-point diamond turning of semiconductors. J Am Ceram Soc 78(8):2015–2020

Shimada S, Ikawa N, Inamura T, Takezawa N, Ohmori H, Sata T (1995) Brittle-ductile transition phenomena in microindentation and micromachining. CIRP Ann Manuf Technol 44(1):523–526

Yan J, Syoji K, Kuriyagawa T, Suzuki H (2002) Ductile regime turning at large tool feed. J Mater Process Technol 121(2–3):363–372

Bhattacharya B, Patten JA, Jacob J (2006) Single point diamond turning of CVD coated silicon carbide. In: ASME 2006 international manufacturing science and engineering conference. American Society of Mechanical Engineers, pp 1153–1158

Patten JA, Jacob J, Bhattacharya B, Grevstad A, Fang N, Marsh ER (2007) Numerical simulations and cutting experiments on single point diamond machining of semiconductors and ceramics. Semiconductor machining at the micro-nano scale. Transw Res Netw Kerala India 2:1–36

Ravindra D, Patten J (2007) Determining the ductile to brittle transition (DBT) of a single-crystal 4H-SiC wafer by performing nanometric cutting. In: Proceedings of ISAAT 2007 on precision grinding and abrasive technology at SME international grinding conference, pp 26–28

Kovalchenko AM (2013) Studies of the ductile mode of cutting brittle materials (a review). J Superhard Mater 35(5):259–276

Hatefi S, Abou-El-Hossein K (2020) Review of single-point diamond turning process in terms of ultra-precision optical surface roughness. Int J Adv Manuf Technol 106(5):2167–2187

Alder BJ, Wainwright T (1957) Phase transition for a hard sphere system. J Chem Phys 27(5):1208–1209

Belak JF, Stowers IF (1990) A molecular dynamics model of the orthogonal cutting process (No. UCRL-102697; CONF-9009241--1). Lawrence Livermore National Lab., CA (USA)

Liu Y, Li B, Kong L (2018) Atomistic insights on the nanoscale single grain scratching mechanism of silicon carbide ceramic based on molecular dynamics simulation. AIP Adv 8(3):035109

Liu Y, Li B, Kong L (2018) A molecular dynamics investigation into nanoscale scratching mechanism of polycrystalline silicon carbide. Comput Mater Sci 148:76–86

Liu Y, Li B, Kong L (2018) Molecular dynamics simulation of silicon carbide nanoscale material removal behavior. Ceram Int 44(10):11910–11913

Wang J, Chi H, Lv M, Liu X, Li Y, Zhao Y (2020) Effect of silicon carbide hard particles scratch on the diamond cutting tools groove wear. Proc Inst Mech Eng C J Mech Eng Sci 234(10):2053–2063

Shimada S, Ikawa N (1992) Molecular dynamics analysis as compared with experimental results of micromachining. CIRP Ann 41(1):117–120

Inamura T, Shimada S, Takezawa N, Nakahara N (1997) Brittle/ductile transition phenomena observed in computer simulations of machining defect-free monocrystalline silicon. CIRP Ann 46(1):31–34

Komanduri R, Chandrasekaran N, Raff LM (2000) MD Simulation of nanometric cutting of single crystal aluminum–effect of crystal orientation and direction of cutting. Wear 242(1–2):60–88

Komanduri R, Chandrasekaran N, Raff LM (2001) Molecular dynamics simulation of the nanometric cutting of silicon. Philos Mag B 81(12):1989–2019

Cheng K, Luo X, Ward R, Holt R (2003) Modeling and simulation of the tool wear in nanometric cutting. Wear 255(7–12):1427–1432

Cai MB, Li XP, Rahman M (2007) Characteristics of “dynamic hard particles” in nanoscale ductile mode cutting of monocrystalline silicon with diamond tools in relation to tool groove wear. Wear 263(7–12):1459–1466

Komanduri R, Raff LM (2001) A review on the molecular dynamics simulation of machining at the atomic scale. Proc Inst Mech Eng, Part B: J Eng Manuf 215(12):1639–1672

Oluwajobi A (2012) Molecular dynamics simulation of nanoscale machining. In: Molecular dynamics-studies of synthetic and biological macromolecules. InTech

Goel S, Luo X, Agrawal A, Reuben RL (2015) Diamond machining of silicon: a review of advances in molecular dynamics simulation. Int J Mach Tools Manuf 88:131–164

Guo X, Li Q, Liu T, Kang R, Jin Z, Guo D (2017) Advances in molecular dynamics simulation of ultra-precision machining of hard and brittle materials. Front Mech Eng 12(1):89–98

Abdulkadir LN, Abou-El-Hossein K, Jumare AI, Liman MM, Olaniyan TA, Odedeyi PB (2018) Review of molecular dynamics/experimental study of diamond-silicon behavior in nanoscale machining. Int J Adv Manuf Technol 1–55

Goel S, Luo X, Reuben RL, Rashid WB (2011) Atomistic aspects of ductile responses of cubic silicon carbide during nanometric cutting. Nanoscale Res Lett 6(1):589

Goel S, Luo X, Reuben RL (2012) Molecular dynamics simulation model for the quantitative assessment of tool wear during single point diamond turning of cubic silicon carbide. Comput Mater Sci 51(1):402–408

Goel S, Luo X, Reuben RL, Pen H (2012) Influence of temperature and crystal orientation on tool wear during single point diamond turning of silicon. Wear 284:65–72

Goel S, Kovalchenko A, Stukowski A, Cross G (2016) Influence of microstructure on the cutting behaviour of silicon. Acta Mater 105:464–478

Li XP, He T, Rahman M (2005) Tool wear characteristics and their effects on nanoscale ductile mode cutting of silicon wafer. Wear 259(7–12):1207–1214

Liu C, He W, Chu J, Zhang J, Chen X, Xiao J, Xu J (2021) Molecular dynamics simulation on cutting mechanism in the hybrid machining process of single-crystal silicon. Nanoscale Res Lett 16(1):1–15

Goel S, Chavoshi SZ, Murphy A (2017) Molecular dynamics simulation (MDS) to study nanoscale machining processes. In: Jain VK (ed), Nanofinishing science and technology: basic and advanced finishing and polishing processes (micro and nanomanufacturing series). Taylor and Francis

Davim JP, Maranhao C, Jackson MJ, Cabral G, Gracio J (2008) FEM analysis in high speed machining of aluminium alloy (Al7075-0) using polycrystalline diamond (PCD) and cemented carbide (K10) cutting tools. Int J Adv Manuf Technol 39(11–12):1093–1100

Davim JP, Reis P, Maranhao C, Jackson MJ, Cabral G, Gracio J (2009) Finite element simulation and experimental analysis of orthogonal cutting of an aluminium alloy using polycrystalline diamond tools. Int J Mater Prod Technol 37(1–2):46–59

Jagadesh T, Samuel GL (2015) Mechanistic and finite element model for prediction of cutting forces during micro-turning of titanium alloy. Mach Sci Technol 19(4):593–629

Jagadesh T, Samuel GL (2017) Finite element simulations of micro turning of Ti–6Al–4V using PCD and coated carbide tools. J Inst Eng (India): Series C 98(1):5–15

Markopoulos AP (2012) Finite element method in machining processes. Springer Science & Business Media

Saini JS, Khera S (2016) Non-linear creep analysis of ceramic specimen using finite element method. J Inst Eng (India): Series C 97(3):417–430.

Ji S, Liu L, Zhao J, Sun C (2015) Finite element analysis and simulation about microgrinding of SiC. Journal of Nanomaterials

Nian D (2020) Effects of depth of cutting on damage interferences during double scratching on single crystal SiC. Curr Comput-Aided Drug Des 10(6):519

Duan N, Yu Y, Shi W, Xiao Q, Liu Q (2021) Investigation on diamond damaged process during a single-scratch of single crystal silicon carbide. Wear 486:204099

Ji S, Liu L, Zhao J, Sun C (2015) Finite element analysis and simulation about microgrinding of SiC. J Nanomater 575398:1–9

Khatri N, Barkachary BM, Muneeswaran B, Al-Sayegh R, Luo X, Goel S (2020) Surface defects incorporated diamond machining of silicon. Int J Extreme Manuf 2(4):045102

Alam M, Zhao L, Vajragupta N, Zhang J, Hartmaier A (2021) Finite Element modeling of brittle and ductile modes in cutting of 3C-SiC. Curr Comput-Aided Drug Des 11(11):1286

Barkachary BM, Joshi SN (2022) Numerical computation and analysis of cutting forces during nanometric scratching of silicon carbide. J Inst Eng (India): Series C 103(1):53–62

Yan J, Zhao H, Kuriyagawa T (2007) finite element analysis of the hydrostatic pressure and temperature in ductile machining of silicon. Adv Abrasive Technol 10:185

Mir A (2016) Investigation of cutting mechanics in single point diamond turning of silicon. Doctoral dissertation, University of Strathclyde

Mir A, Luo X, Sun J (2016) The investigation of influence of tool wear on ductile to brittle transition in single point diamond turning of silicon. Wear 364:233–243

Mir A, Luo X, Siddiq A (2017) Smooth particle hydrodynamics study of surface defect machining for diamond turning of silicon. Int J Adv Manuf Technol 88(9–12):2461–2476

Zhang S, Zong W (2020) Micro defects on diamond tool cutting edge affecting the ductile-mode machining of KDP crystal. Micromachines 11(12):1102

Klippel H, Süssmaier S, Röthlin M, Afrasiabi M, Pala U, Wegener K (2021) Simulation of the ductile machining mode of silicon. Int J Adv Manuf Technol 115(5):1565–1578

Liu Y, Li B, Wu C, Kong L, Zheng Y (2018) Smoothed particle hydrodynamics simulation and experimental analysis of SiC ceramic grinding mechanism. Ceram Int 44(11):12194–12203

Acknowledgements

This paper is an expanded version of an article entitled, “Ultra-precise single-point diamond turning process and its low-cost alternative methods” presented in “North East Research Conclave 2022” held at Indian Institute of Technology Guwahati, North Guwahati, India, during 20-22 May 2022. The work presented in the paper has not received any grants or support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Barkachary, B.M., Joshi, S.N. (2023). Ultra-Precise Single-Point Diamond Turning Process and Its Low-Cost Alternative Methods. In: Joshi, S.N., Dixit, U.S., Mittal, R.K., Bag, S. (eds) Low Cost Manufacturing Technologies. NERC 2022. Springer, Singapore. https://doi.org/10.1007/978-981-19-8452-5_8

Download citation

DOI: https://doi.org/10.1007/978-981-19-8452-5_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-8451-8

Online ISBN: 978-981-19-8452-5

eBook Packages: EngineeringEngineering (R0)