Abstract

Considering the EU environmental standards for non-road mobile machinery (NRMM), reducing pollutant emissions from inland waterway vessels is becoming increasingly important. The RIVER research project aims to find solutions to achieve nitrogen-free combustion in waterways transportation systems while also emitting zero CO2 emission. RIVER addresses these issues using Carbon Capture and Storage (CCS) technology and Oxy-fuel combustion (OFC). The project is co-financed by the European Union, as part of the Interreg North-West Europe program. There are ten partners involved in this project (FR, UK, GE, NL, LU). In OFC technology, pure oxygen is used instead of air. Due to the absence of N2 in the intake charge, NOx emissions will be eliminated. Consequently, the only products of combustion are CO2 and water vapor. To have a stable combustion process and avoid overheating problems caused by using pure oxygen, some part of the exhaust CO2 will be recirculated to the engine to create an oxygen-CO2 mixture for being fed into the engine. A detailed CFD simulation carried out in this project has revealed that 21% oxygen and 79% carbon dioxide is the ideal mixture for the engine to run at maximum efficiency. The remaining CO2 from the exhaust is collected. It is then condensed, compressed, and stored in a tank to be valorized later. It will be transformed into cosmetics, skincare products, and formic acid. These types of acids are used by the medical sector as an anti-rheumatic product. River's final demonstration will take place in Crewe, UK in July 2022.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The global warming problem has been significantly exacerbated by greenhouse gas emissions (GHG) over the last few decades (Kanniche et al. 2010; Wang et al. 2015). The transportation sector consumes twenty percent of global fossil fuel production which puts it second in terms of emission of carbon dioxide (CO2) and consequently, contributes to alarmingly increasing levels of atmospheric CO2 and associated greenhouse gases. The European Union has set a target of less than 59 g/km of CO2 tailpipe emissions in 2030, meaning that a 37.5% reduction is required through this decade. Discussions are underway to further reduce the target to align it with the European Green Deal, which is aiming for net-zero greenhouse gas (GHG) emissions by the year 2050. There have been several initiatives proposed to deal with the deteriorating climate crisis, including carbon neutrality (Figueroa et al. 2008; Li et al. 2021, 2022).

In 2017, the European Union adopted regulations requiring limits on carbon emissions and certification of internal combustion engines used in nonroad mobile machinery (Directive 97/68/EC). As a result, inland waterways (IW) vessels must now comply with more strict emission standards. In project RIVER, the goal is to find solutions to achieve nitrogen-free combustion in waterways transportation systems while also emitting zero carbon dioxide (Aitouche 2022).

It has been proposed that oxygen enriched combustion and oxy-fuel combustion (OFC) are an efficient way to increase engine efficiency and reduce pollutant emissions. OFC combustion uses pure oxygen for combustion instead of air. Due to the absence of N2 in the intake charge, NOx emissions will be eliminated. As a result, carbon dioxide and water vapor are the only products of combustion. Studies to date have been mainly focused on applying oxy-fuel or oxygen enriched combustion technologies to gas turbines and coal-fired power plants. The utilization of OFC and CO2 capture for IC engines has been gaining a lot of attention during the last few years. Research on oxygen-enriched combustion shows that a slight increase in oxygen reduces smoke emissions as well as the amount of CO and unburnt hydrocarbons but increases the amount of nitrogen oxides (NOx). Various technologies have been used to decrease NOx and particulates, such as exhaust gas recirculation (EGR) and optimum injection strategies. Research conducted recently has drawn attention to oxy-fuel and nitrogen-free combustion because of the benefits it brings to vehicles and is being used to make huge improvements to the efficiency of internal combustion engines and to achieved zero NOx emissions. As is known, over-high peak pressures and peak pressure increases can easily appear in engine cylinders in oxygen-enriched conditions. An increase in combustion flame temperature is expected if oxygen is used instead of air. To minimize overheating problems due to overheating, it is crucial that the fuel injection flow rate be accurately controlled in order to eliminate unexpected temperature rises in the premixed and diffusion combustion. Further, the diluent ratio and intake charge temperature have a meaningful impact on controlling in-cylinder temperature and combustion process (Giorgi et al. 2021).

Homogeneous Charge Compression Ignition (HCCI) is one of the low-temperature combustion regimes being researched for internal combustion engines. The HCCI concept has been widely studied as a promising concept since it produces emissions comparable to those of a SI engine while achieving thermal efficiency comparable to diesel engines with direct injection. As a result of the auto-ignition occurring nearly simultaneously over the entire combustion chamber, HCCI engines have limited power density. The rapid energy release leads to a large pressure rise in the combustion chamber under high load, causing pressure oscillations. Additionally, HCCI combustion often suffers from the lack of proper combustion phasing. HCCI combustion is initiated by chemical kinetics: the high propensity of diesel fuel to auto-ignite combined with the high compression of diesel engines results in combustion starting before top dead center, very rapid pressure raises rates, short combustion durations.

The current project, which is part of a European project called RIVER (funded by Interreg North-West Europe), aims to examine how different intake charge temperatures may affect oxy-fuel combustion in HCCI mode.

2 River Project Proposed Technology

Equation (1) and Eq. (2) present the chemical reaction process of conventional air combustion (CAC) and OFC, respectively. Unlike with the CAC, the main feature of OFC is oxygen replaces air to react with fuel directly, leading to the chemical products merely contain CO2 and H2O.

Moreover, compared to nitrogen of air, the main discrepancies in physicochemical properties for CO2 can be found in Table 1, which would affect the combustion characteristics of OFC under some specific conditions (Wall et al. 2009; Chen et al. 2012). Regarding molecular weight, CO2 is 57% higher than that of nitrogen. Hence, under the conditions of OFC, the combustion temperature will be adversely affected due to the higher heat capacity on mole basis of CO2. In addition, under OFC, chemical reaction rates at early combustion stage would be potentially reduced owing to the low thermal diffusivity and oxygen diffusion of CO2.

The RIVER project's primary goal is to eliminate NOx emissions from inland boat engines as well as to capture and store carbon emissions from these engines. These issues are addressed through the use of Carbon Capture and Storage (CCS) technology and OFC in RIVER. A summary of the RIVER technology can be seen in Fig. 1.

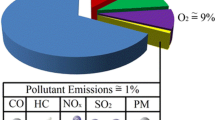

As shown in Fig. 1, power is supplied to the boat by a diesel generator. The engine operates in HCCI mode. There are three components involved in oxyfuel combustion: the oxygen supply system, the exhaust gas recirculation system, and the carbon capture system. Oxygen is provided by a commercial high-pressure oxygen cylinder. CO2-rich exhaust gases are condensed in the condenser, followed by the separation of water from it. Following recirculation, a portion of the remaining CO2 is recirculated back into the engine through EGR and mixed with oxygen prior to being used. Meanwhile, the rest of the CO2 is compressed and stored. It is predicted that this technology will eliminate NOx emissions while storing 100% of carbon dioxide. Optimizing oxy-fuel HCCI combustion requires using an appropriate oxygen concentration and EGR ratio. The authors examined how oxygen and carbon dioxide percentages affected combustion characteristics and engine operating conditions of OFC under HCCI mode. In the current study, the effect of intake charge temperature is discussed. This goal has been accomplished by studying the effects of five different intake charge temperatures on engine operating conditions for diluent strategies. The proposed idea in this study to apply oxy-fuel provides a significant advantage over previous studies in that the diluent strategy is integrated with HCCI combustion to control OFC process instead of water, which can eliminate problems associated with water injection such as lubrication and corrosion.

Because CO2 is released at the outlet of the engine, no CO2 is present during startup. It is being proposed to start the engine with an air mixture and wait a few cycles before switching to an oxygen/CO2 mixture. Alternatively, install a tank in which CO2 will be stored and solely used for starting. Both techniques have been tested, and both are effective. We will carry out tests under real conditions to see which works best. The ideal solution would be to use CO2, as we don’t take the risk of producing nitrogen oxide, which will mix with the CO2.

Many boats in recent years have been equipped with exhaust gas recirculation (EGR) valves, making their installation of this technology much easier. However, this equipment must be added to older boats. All engines must be also equipped with oxygen supply valves. On smaller boats, oxygen can be provided by cylinders, but on larger boats, it should be produced on-site due to the large quantities needed. It must be noted the way to produce oxygen is much simpler than to produce hydrogen: Furthermore, oxygen does not have to be pure like in fuel cells, even 95% pure oxygen can be used.

The effect of different diluent strategies on in-cylinder cylinder pressure, and in-cylinder temperature are shown in Fig. 2 and Fig. 3, respectively, under a constant intake temperature and intake pressure.

As illustrated in Fig. 2 and Fig. 3, the increase of intake-air oxygen content from 15% to 21% results in a significant increase of peak in-cylinder pressure and peak in-cylinder temperature after TDC. In addition, it tends to advance peak pressure location and peak temperature location due to a significantly advanced main combustion process. Highest values of peak in-cylinder pressure and in-cylinder temperature are observed for the highest oxygen percentage (21%v/v). Applying oxy-fuel HCCI combustion instead of conventional HCCI combustion leads to acceleration of the combustion process which results in a shorter ignition delay period. In addition, premixed combustion is minimized while diffusion combustion is maximized. With the heat release rate dramatically increased, it takes a much shorter time to complete the entire heat release process. Subsequently, with such a high heat release rate, the in-cylinder temperature and in-cylinder pressure have increased.

In Table 2, it shows the amount of CO and PM emissions. The results indicate that the oxy-fuel HCCI combustion has brought the CO and PM emissions to a very ultra-low level while the NOx emission has been eliminated using the oxy-fuel combustion. In Table 1, LambdaO2 is defined as follow:

In addition, Fig. 4 and Fig. 5 shows the design and technical drawings of the whole after-treatment system in RIVER project. The system mainly involves a two-stage heat exchanger, water/gas separator, CO2 compressors, CO2 tank, required valves, controller, pipes, etc. The excess CO2 exhaust gas can be captured and stored in a storage tank to achieve zero carbon emissions. Furthermore, based on some initial simulation work in advance, the system would provide a good cooling capability, effectively reducing the exhaust temperature from around 800 K to 330 K before entering into the CO2 tank.

3 Conclusions

A technology has been proposed by the RIVER project to eliminate pollutant emission for the water transportation systems using CCS and OFC techniques. An advanced CFD simulation using detailed chemistry has been applied to explore the effect of different strategies on engine performance and the amount of pollutant emissions. Besides, a novel design and technical drawings of the after-treatment system of OFC has also been presented. The following conclusions may be drawn:

-

Because no nitrogen is present in the intake charge of an oxy-fuel combustion, nitrogen oxides are eliminated. Consequently, combustion reactions produce CO2-rich emissions. In all cases investigated, PM emissions were very low (<0.0004 gr/kg.fuel) and NOx emissions were eliminated when using OFC HCCI.

-

The proposed application of oxy-fuel in this study offers a significant advantage over previous studies in that a diluent strategy is used to control oxy-fuel combustion instead of water, thus eliminating problems associated with water injection such as lubrication and corrosion.

References

Aitouche A (2022) An overview of River Project. In: Workshop of prevention of pollution for inland waterway vessels and greening of the inland water transport. UECE, Division on sustainable transport, 16 February 2022, Genova, Switzerland

Chen L, Yong SZ, Ghoniem AF (2012) Oxy-fuel combustion of pulverized coal: characterization, fundamentals, stabilization and CFD modeling. Prog Energy Combust Sci 38(2):156–214

Figueroa JD, Fout T, Plasynski S, McIlvried H, Srivastava RD (2008) Advances in CO2 capture technology—the US Department of Energy’s Carbon Sequestration Program. Int J Greenhouse Gas Control 2(1):9–20

Giorgi S, Vera-Quintana S, Mobasheri R, Aitouche A (2021) A CFD investigation into the effects of intake air oxygen enrichment on DI diesel engine combustion and emissions. In: 9th international conference on systems and control (ICSC), November, Caen, France, pp 24–26

Kanniche M, Gros-Bonnivard R, Jaud P, Valle-Marcos J, Amann JM, Bouallou C (2010) Pre-combustion, post-combustion and oxy-combustion in thermal power plant for CO2 capture. Appl Therm Eng 30(1):53–62

Li X et al (2022) Oxy-fuel combustion for carbon capture and storage in internal combustion engines–a review. Int J Energy Res 46(2):505–522

Li X, Pei Y, Ajmal T, Aitouche A, Mobasheri R, Peng Z (2021) Implementation of oxy-fuel combustion (OFC) technology in a gasoline direct injection (GDI) engine fuelled with gasoline–ethanol blends. ACS Omega ACS Publ 6(44):29394–29402

Wall T et al (2009) An overview on oxyfuel coal combustion—state of the art research and technology development. Chem Eng Res Des 87(8):1003–1016

Wang M, Joel AS, Ramshaw C, Eimer D, Musa NM (2015) Process intensification for post-combustion CO2 capture with chemical absorption: a critical review. Appl Energy 158:275–291

Acknowledgements

The authors gratefully acknowledge the financial support of the Interreg North-West Europe (RIVER Project No. NWE553). Additionally, the authors would like to thank the AVL Company for their collaboration in this work to provide the AVL simulation software at JUNIA, France.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Aitouche, A. et al. (2023). River Project, An Innovative Way to Reduce Pollution on Riverboats. In: Li, Y., Hu, Y., Rigo, P., Lefler, F.E., Zhao, G. (eds) Proceedings of PIANC Smart Rivers 2022. PIANC 2022. Lecture Notes in Civil Engineering, vol 264. Springer, Singapore. https://doi.org/10.1007/978-981-19-6138-0_80

Download citation

DOI: https://doi.org/10.1007/978-981-19-6138-0_80

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-6137-3

Online ISBN: 978-981-19-6138-0

eBook Packages: EngineeringEngineering (R0)