Abstract

There are many types of navigation lock filling and emptying systems, how to choose the appropriate hydraulic system is the key issues in the design of navigation lock. At present, there is no unified method and standard for the decision of the navigation lock filling and emptying system. In Chinese design codes, the traditional way to choose the lock hydraulic system types is based on the m coefficient which is related with the lock lift height (H) and leveling time(T). The influence of dimension of lock chamber is ignored in the method, including the length, width and initial water depth etc. which makes it difficult to choose an accurate and reasonable F/E system. In this paper, according to the energy dissipation mechanism of the filling and emptying system, combined with the influences of water head, filling and emptying time, chamber dimension and initial water depth, except the traditional discrimination index m, two dimensionless indexes mL and mC are introduced, which respectively represent the energy that needs to be eliminated in the horizontal, vertical and horizontal unit area of the F/E system. And the lock hydraulic system is classified into 7 categories based on the layout and energy dissipation characteristics of F/E system. The decision indexes of over 100 navigation locks with different characters are counted, then the relationship between the indexes and 7 lock hydraulic system categories is established using gray system theory. Finally, using the filling and emptying system selection method, the filling and emptying system of 13 typical ship locks are calculated and compared with the industry codes. The results show that this method quantifies the filling and emptying system selection process; the filling and emptying system selected by this method has high accuracy and good practical value.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

According to the layout of the water outlet of the lock chamber and the energy dissipation method, it is mainly divided into two categories: end filling and emptying system and longitudinal culvert filling and emptying system (NHRI 2005). Both of them can be subdivided into many types depending on the range of application. Taking the longitudinal culvert filling and emptying system as a column, there are more than 10 kinds of filling and emptying systems commonly used, such as the side orifice longitudinal culvert filling and emptying system, the bottom longitudinal culvert filling and emptying system with side ports and open ditches, and so on. At present, there is no unified method and standard for the decision of the navigation lock filling and emptying system at home and abroad. How to choose the appropriate filling and emptying system is the most concerned problem in the design of navigation lock.

In the Soviet Union, the key consideration in the design of lock is project investment. It is believed that when the water head is not large (the water head is below 15m), compared with the longitudinal culvert filling and emptying system, the engineering cost of the end filling and emptying system can be reduced by 10% to 60%. When L·H < 2000 m2 (L is the length of the lock chamber, H is the design head of the lock) and H/hk < 3 (hk is the water depth on the sill of the lock chamber), an end filling and emptying system can be used regardless of the demonstration. Only when the water head exceeds 18–20 m, consider using a longitudinal culvert filling and emptying system (B.д 1964). Choosing the water delivery system according to this standard often results in poor berthing conditions in the lock room, which is rarely used at present.

In the navigation lock design manual revised by the U.S. Army Corps of Engineers in 1985 (US Army Corps of Engineer 2006), the water head classification and the respective applicable filling and emptying systems are specified as follows, see Table 1. This method only considers the impact of the ship lock head and the decision of filling and emptying system is conservative. If the water head exceeds 12.2 m, it is recommended to use the inertial bottom longitudinal corridor filling and emptying system, which leads to large investment and poor economy in lock construction. The International Chamber of Shipping in 1986 (PIANC 1986) divided the lock head into three levels of less than 10.0 m, 10.0–15.0 m and greater than 15.0 m, and divided the filling and emptying system into three levels: simple, medium, and complex. Different water heads choose different filling and emptying system with different complexity.

In < Design Code for Filling and Emptying System of Ship locks > ( JTJ306—2001) (referred to as “Code”), choose the form of filling and emptying system according to the discriminant coefficient m calculated by formula (1), when m > 3.5, use end filling and emptying system; when m > 2.4, the first type of longitudinal culvert filling and emptying system can be used; when 1.8 ≤ m ≤ 2.4, the second type of longitudinal culvert filling and emptying system can be used; when m < 1.8, the third type of longitudinal culvert filling and emptying system can be used; when 2.5 ≤ m ≤ 3.5 At the time, end filling and emptying system or a simple longitudinal culvert filling and emptying system can be used.

In the formula: m is the discriminant coefficient; H is the design head (m); T is the design water delivery time (min).

Compared with the filling and emptying system decision for navigation lock abroad, in addition to the ship lock design head H, the Chinese code has increased the impact of the water delivery time T, and made a more detailed classification of the filling and emptying system. PIANC also recommended it in 2009 (PIANC 2009).This method also does not consider the influence of the ship lock's plane dimensions, the initial water depth of the lock chamber, and other factors, resulting in the filling and emptying system selected by the value of m that cannot meet the actual requirements, as shown in Table 2.It can be seen that the design head and water delivery time of Xijiang Changzhou 1# and 2# ship locks are exactly the same, m are both 2.54, and the effective plane dimensions of the ship lock are 200.0 m × 34.0 m and 190.0 m × 23.0 m, respectively. The 1# ship lock selected the second type of longitudinal culvert filling and emptying system which is more complex and has better energy dissipation effect.

At the same time, the current standard m deviates from the actual selection of the filling and emptying system. For example, the head of the Qianjiang Datengxia ship lock reached 40.1 m, which is the single-stage ship lock with the largest water head in the world. The water delivery time is 15 min and the m value is only 2.37. According to the code, the second type of longitudinal culvert filling and emptying system can be selected, but the most complicated third type of longitudinal culvert filling and emptying system is actually selected. In addition, in the actual application process, there are many types of navigation lock filling and emptying systems. Only the second type of filling and emptying system in Chinese code has more than 10 forms. The code does not quantify the water delivery system and the discrimination coefficient. The above factors bring great difficulties to the selection of the ship lock water conveyance system.

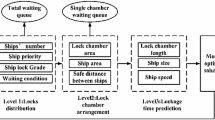

2 Model of Filling and Emptying System Selection

2.1 Selection method

The selection of the filling and emptying system of the ship lock requires comprehensive evaluation of the influences of many factors such as the design head, the time of filling and emptying, the plane dimension and the initial water depth of the lock. At present, the comprehensive evaluation methods considering the influence of multiple factors mainly include analytic hierarchy process, fuzzy comprehensive evaluation, data envelopment analysis, artificial neural network evaluation and gray comprehensive evaluation (Du et al. 2008). Each of these evaluation methods has its own characteristics. Analytic hierarchy process (AHP) is mainly aimed at the decision problems of basic scheme determination and is generally only used for scheme optimization (Wang et al. 2020). The data envelopment analysis method is completely based on the objective information of the index data and eliminates the error caused by human factors. Artificial neural network (Ann) is a new evaluation method for complex systems. The grey comprehensive evaluation method quantitatively represents the degree of correlation between various factors, and is essentially a comparison of the characteristic parameters between the evaluation object and the reference object. The closer the characteristic parameters are, the closer the evaluation object is to the reference object (Gao 2012). The absolute correlation is a method to quantify the correlation between several factors in the grey comprehensive evaluation method, which does not require too much data. In this method, H = {Xi| i ∈ I = {0,1,2, 3,…,m}} is factor set (association space), X0 ∈ H is reference factor column, X0 = {x0(k) | k = 1,2,…n}, Y ∈ H is comparison factor column, Y = {y(k) | k = 1,2,…n}, then the absolute correlation of comparison factor column Y to reference factor column X in H can be calculated as follows:

In the formula: “∧”means take small and “∨” means take a big; R (X0, Y) means absolute correlation, the higher the value of R (X0, Y), the higher the correlation.

According to the above method, the lock filling and emptying system can be divided into i types according to certain characteristics. Through statistical analysis of the characteristic parameters of different types of filling and emptying system, establish the reference sequence Xi = {xi(k) | k = 1,2,…n} of influencing factors of class i, calculate the correlation \(R(X_{i} ,Y)\) of the ship lock between the comparison index sequence Y = {y(k) | k = 1,2,…n} and the reference sequence. If the correlation between Y and Xi is the greatest, the i type of filling and emptying system is selected.

2.2 Classification of Filling and Emptying System

According to the layout and energy dissipation characteristics of different types of filling and emptying systems, based on the types in China codes, the commonly used forms of filling and emptying systems from simple to complex at present mainly include the following 7 categories:

-

1)

End filling and emptying system. The water flow is fed into the chamber from the end of the chamber and flows from one head to another.

-

2)

Partial longitudinal culvert filling and emptying system. The filling is “Through longitudinal culvert” system, the emptying is“through the heads” system.

-

3)

The Type I filling and emptying system, such as the side orifice longitudinal culvert filling and emptying system.

-

4)

The Type IIa filling and emptying system, such as the bottom longitudinal culvert filling and emptying system with side ports and open ditches, the bottom longitudinal culvert filling and emptying with side branch hole and so on, Its characteristic is that there is no branch corridor and no partition in the filling and emptying system.

-

5)

The Type IIb filling and emptying system. It is characterized by transverse branch corridors arranged in the gate chamber and no longitudinal branch corridors.

-

6)

The Type IIc filling and emptying system. It includes the filling and emptying system of the vertical and horizontal branches of the gate, and the filling and emptying system of the bottom branch of the horizontal diverter gate, etc. Its characteristics are that the filling and emptying system is divided in the gate chamber, the water flow enters through the middle corridor of the gate, and the longitudinal branch corridor is set up.

-

7)

The Type III filling and emptying system is regulated by Chinese codes, such as Iso-inertial stereo distributary multistage decentralized filling and emptying system, characterized by the inertia arrangement of the system. The first shunt is three-dimensional.

2.3 Discriminant Index of Filling and Emptying System

From the perspective of the hydraulic filling and emptying system, the selection of filling and emptying system mainly affected by many factors like design head H, lock chamber length L and width W, the initial water depth S, lock filling time T. How to quantify the influence of various factors and establish the quantitative evaluation index of various types of filling and emptying system is the key to establish the selection model of filling and emptying system. The essence of the selection of the ship lock filling and emptying system is to select the appropriate form to eliminate the water flow energy entering the lock chamber. According to the equation of ship lock water conveyance energy, the maximum energy entering the lock chamber during the process of filling and emptying can be expressed as (Wang 1992):

The water flow energy that needs to be eliminated per unit area of the lock water surface, longitudinal and transverse can be expressed as:

In the formula, \(E_{\max }\) is maximum energy of water delivery; C is the calculation of water area of the gate chamber, the multi-stage lock takes half of the water area of the lock chamber(m2); Kv is the ratio of valve opening time tv to lock filling and emptying time T; \(E_{H}\) is the horizontal unit area energy of the lock chamber; \(E_{L}\) is the energy per unit longitudinal area of the lock chamber; \(E_{C}\) is the energy per unit area of the lock chamber.

Define three dimensionless variables \(m_{H} = \frac{{CH^{2} }}{TLB}\), \(m_{L} = \frac{{CH^{2} }}{TLD}\), \(m_{C} = \frac{{CH^{2} }}{TBD}\) which include the influences of lock acting head H, lock filling and emptying time T, effective length L, effective width B, initial water depth D and water area C of lock chamber.

It can be seen from the above that mH, mL, mC, these three dimensionless variables, respectively represent the energy that needs to be eliminated in the horizontal, vertical and horizontal unit area of the filling and emptying system. In fact, the discriminant coefficient m of the ship lock filling and emptying system in China represents the energy of elimination per unit area of the water surface of the system. In order to be consistent with the current code, the value m is still used as the index of the energy per unit area of the water surface of the ship lock.

In order to analyze the actual elimination energy per unit area of different types of filling and emptying systems, the value of m, mL, mC, of 123 large ship locks (Li et al. 2020) at home and abroad are calculated and analyzed according to the above method, as shown in Fig. 1 and 2.Among them, there are 23 end filling and emptying systems with an average acting head of 6.7 m.There are 5 partial longitudinal culvert filling and emptying systems with an average acting head of 9.0 m.There are 45 TypeIfilling and emptying system, with an average acting head of 11.5 m; 28 TypeIIa filling and emptying systems, with an average acting head of 18.6 m;12 TypeIIb filling and emptying systems, with an average acting head of 25.7 m; 3TypeIIb filling and emptying systems, with an average acting head of 28.4 m. The TypeIII filling and emptying system has 7 seats with an average acting water head of 37.0 m.

According to the classification standard of filling and emptying system, the mean values of m, mL, mC of 7 types of filling and emptying system are statistically analyzed, as shown in Table 3. According to the grey comprehensive evaluation method, the index reference sequence of influencing factors of filling and emptying system \(X_{i} = \left\{ {m_{i} ,m_{Li} ,m_{Ci} } \right\},i = 1,...,7\), respectively represent the 7 types classified in Sect. 2.2.

3 Applications

The parameters of 13 constructed or under construction ship locks with different water heads, plane dimension, initial water depth and lock filling and emptying time were selected for the decision of filling and emptying system (Li et al. 2020; Xuan et al. 2003; Li et al. 2005; Xuan et al. 2011; Li, et al., 2017).The acting head of the test lock is 7.0–45.2 m, the length of lock chamber varies from 120–300 m, the width of the lock chamber varies from 12 to 34 m, the initial water depth of the lock chamber is 3.0–10.0 m, and the lock filling and emptying time is 8.0–16.0 min. See Table 4 for the specific characteristic parameters of each test lock.

Table 5 shows the results of the calculated correlation between 13 ship locks and different types of filling and emptying system and is sorted according to the absolute correlation. The greater absolute correlation indicates that the lock is more suitable for the filling and emptying system. It can be seen from Table 6 that the 12 types of filling and emptying system selected by the method in this paper compared with the actual form used in the project are obviously superior to the current codes in terms of the type decision.

4 Conclusions

-

1)

The non-dimensional discriminant coefficient of filling and emptying system m,\(m_{L} = \frac{{CH^{2} }}{TLD}\), \(m_{C} = \frac{{CH^{2} }}{TBD}\) can comprehensively reflect the influences of design head, plane scale of lock chamber, initial depth of water level and time of lock filling and emptying on the selection of filling and emptying system of ship lock.

-

2)

The model is used to calculate the filling and emptying system of 13 typical ship locks, and the results show that the form of filling and emptying system calculated by the model is basically consistent with the form of filling and emptying system adopted in the engineering practice, which is not only the selection results are obviously better than the current specifications, but also the selection results can be quantified and good practicality.

References

Nanjing hydraulic research institute (2001) Code for design of ship lock filling and emptying system. JTJ306—2001

B.д. (1964) Hydraulics of ship lock

US Army Corps of Engineer (2006) Hydraulic design of navigation locks EM1110–2–1604. USACE

PIANC (1986) Final report of the international commission for the study of locks. PIANC

PIANC (2009) Innovations in navigation lock design NO. 106. PIANC

Huang Y, Cao FS (2019) Study on selection standard of ship lock filling and emptying system. China Water Transp. 19(05):114–116

Du D, Pang QH, Wu Y (2008) Modern comprehensive evaluation method and case selection

Wang DY, Cheng MY, Huang HJ (2020) Study on influencing factors of ship lock capacity based on analytic hierarchy process. Port Waterw Eng. 6:154–158

Gao L (2012) Research on application of multi-level grey evaluation method in ship recycling. Dalian Maritime University

Wang ZG (1992) The Design of Ship Lock. Water Conservancy and Electric Power Press

Li ZH, Xuan, GX (2020) Research report on selection of navigable buildings. NHRI

Li ZH, Xuan GX (2020) Report on key technology of filling and emptying system of 60m single stage giant lock. NHRI

Xuan GX, Li, ZH, Huang, Y. Study on model test of ship lock filling and emptying system of Guangxi Changzhou Hydro-junction. NHRI (2003)

Li ZH, Xuan GX, Huang Y: Hydraulic study on filling and emptying system of Qiaogong Lock, Hongshui River, Guangxi. NHRI (2005)

Xuan GX, Liu, BQ, Huang Y (2011) Study on the layout, hydraulic characteristics and model test of filling and emptying system of ship lock of Fuchun River reconstruction project. NHRI

Li J, Xuan GX, Huang Y (2017) Study on optimal layout and hydraulic physical model test of filling and emptying system of ship lock of Datengxia Hydro-junction. NHRI

Acknowledgements

This paper is supported by the National Key Research and Development Program of China (Grant No. 2016YFC0402001), the Science Foundation of NHRI (Grant No. Y120011).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Li, Z., Xuan, G. (2023). The Approach of Lock Hydraulic System Selection Based on Multiple Factors. In: Li, Y., Hu, Y., Rigo, P., Lefler, F.E., Zhao, G. (eds) Proceedings of PIANC Smart Rivers 2022. PIANC 2022. Lecture Notes in Civil Engineering, vol 264. Springer, Singapore. https://doi.org/10.1007/978-981-19-6138-0_60

Download citation

DOI: https://doi.org/10.1007/978-981-19-6138-0_60

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-6137-3

Online ISBN: 978-981-19-6138-0

eBook Packages: EngineeringEngineering (R0)