Abstract

When designing navigation locks, several parameters must be considered: Apart from the construction and operation costs also the operation speed and lockage safety must be considered. The safety of the lockage is often expressed in terms of the acceptable ship forces. Traditionally, apart from physical models different kinds of numerical models are used to determine the speed and safety of operation: During the predesign phase often simple analytical approaches are used, while in later design phases more sophisticated one- or three-dimensional numerical models or physical models are used independently or in a hybrid modelling approach. With these models the flow rates, the development of the water levels and the resulting forces on the ship can be computed or measured. While the application of three-dimensional numerical models for the lock filling process was in the past limited to very few and extraordinary projects, nowadays their application becomes more and more engineering practice. Here we are giving an overview of the numerical modelling methodologies and are presenting the state-of-the-art for three-dimensional numerical models.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

For a valid hydraulic design of a lock, several parameters must be considered and be balanced with the costs for construction and operation. This includes the physical properties of the flow (e.g. pressures or velocities) as well as the speed and safety of the lockage. The safety is mostly expressed in terms of the allowable ship forces (PIANC 2015; Belzner 2018). Numerical models are often used to determine the speed and safety of operation during the hydraulic design. The level of sophistication is typically coupled to the planning stages. In early phases simple models are used, because they are fast to apply, but possibly rough in terms of accuracy. In later phases, more accurate models are required to validate and optimize the design. With these models the flow rates, the development of the water levels and the resulting forces on the ship can be computed or measured.

While the application of three-dimensional numerical models for the lock filling process was in the past limited to very few and extraordinary projects, nowadays their application becomes more and more engineering practice. For the design of locks it is very helpful to evaluate specific features (e.g. pressure or velocity distributions) of the flow with these models. One must be aware that considering all aspects of the lock filling process offers several pitfalls which might be unexpected, particularly for modellers unexperienced with this specific topic. This is especially problematic if the modeller is already familiar with numerical modelling concepts in general (e.g. from finite element analysis of structures) and tries to transfer this knowledge to the process of lock filling: Unfortunately, with the available numerical modelling packages it is possible to produce valid looking results for the lock filling simulations even if the physical meaning is limited or if the results are plainly wrong. In this situation it is necessary that the modeller has an in-depth knowledge of the expected behaviour of the flow and of the ship in the chamber, in order to judge the quality of the numerical results.

2 Classes of Commonly Used Numerical Models

2.1 Introduction

Over the last decades, numerical models have developed into an irreplaceable tool for the hydraulic design of locks. Depending on the planning stage, the complexity and importance of the project, they are applied either alone, in combination with each other or with physical models. In Thorenz (2009) and De Mulder (2011) an overview of the state-of-the-art in that time was given. Looking back at these considerations, the methods presented then are still valid and in use. But with the further advance of computer technology, the application of three-dimensional numerical models has become more standard for the engineering practice. This is currently typically limited to singular aspects of the flow field, but promising research results are available now for the complete locking process. The simulation of the whole lock filling system, with all of its aspects (i.e. with opening of the valves and moving of the ship) is still challenging and thus must be based on a proper validation with physical model data.

2.2 Zero-Dimensional Numerical Models and Analytical Approaches

Based on the governing analytical equations for the lock filling process, it is possible to compute the temporal development of the water levels in the lock chamber for different valve schedules, configurations etc. by hand or with a spreadsheet program. This requires that the hydraulic parameters of the filling system are known with sufficient accuracy. These parameters can be determined either on the basis of physical model measurements, high-quality three-dimensional numerical models or by prototype measurements. If additional physical effects like wave propagation or jet effects on the vessel are regarded with analytical approaches, even the order of resulting longitudinal ship forces can be computed.

It must be pointed out that this kind of model is typically used only for through-the-head filling systems. The results depend heavily on the chosen parameters and thus on the availability of calibration data. The big advantage of this kind of models is that the results are available more or less instantaneously and thus make parameter studies easy. All relevant effects must be described by analytical approaches, which requires a deep understanding of the hydromechanics of the lock filling process.

2.3 One-Dimensional Numerical Models

In the last decades, one-dimensional numerical models have become a de-facto standard in the pre-dimensioning phase of the design process. Three types of models can be distinguished:

-

Models, that represent the flow in the lock chamber by a set Saint-Venant equations, i.e. by discretizing the chamber in the longitudinal direction.

-

Models, that represent a complex filling system by a network of pipes, connectors and loss coefficients, but represent the chamber only as basin with no spatial discretization.

-

Models which combine the two aforementioned approaches.

With the one-dimensional chamber models, only effects on the vessel in the longitudinal direction can be computed. The models are typically used to compute filling times and longitudinal forces on the vessel etc. They are useful to pre-dimension valve sizes and valve schedules for locks with through the head filling systems. The popular “LockFill” program (De Loor et al. 2013; available at https://oss.deltares.nl/web/lockfill/) is a hybrid program, which contains zero-dimensional and one-dimensional model parts. It is specifically tailored for through the head filling systems. Sometimes, a coupling of the one-dimensional chamber model with a network model for the filling system is incorporated (“LockSim”, Schohl 1999). This facilitates the usage for more complex filling systems like longitudinal culvert systems, but is also still restricted to the longitudinal processes in the lock chamber. In other programs (“LoMo”, Belzner et al. 2018; available at https://github.com/baw-de/lomo), the results of externally computed flow distributions can be fed in any spatial distribution and with variable momentum impact into the one-directional computational core which computes the flow in the lock chamber, thus enabling more complex flow situations.

For all of these programs it must be pointed out, that a proper usage requires understanding of the hydraulic behaviour of the lock filling system. The results depend heavily on the chosen coefficients, which can roughly be estimated for simple systems by expert knowledge. For more complex or new systems, parameter determination by physical or three-dimensional numerical modelling or by prototype measurements is necessary. Thus, the used parameters must be chosen on a reliable basis, as they have a fundamental impact on the results.

As an example, for the lock chamber modelling class of programs, Fig. 1 presents a typical result of LoMo, showing the user interface in the left panel and the computed flow rates (green), water levels (blue) and ship forces (yellow) in the right panel. The user has to set the correct values in the left panel. While the geometry parameters are easily chosen, the parameters under the “Filling” tab require deeper knowledge in order to describe the hydraulic behaviour correctly.

For the computation of the flow in filling system networks, different tools are available. Figure 2 shows a network for a complex filling system with a lock chamber in the middle of the network, longitudinal culverts along the chamber and a set of water saving basins connected to the filling system (Thorenz 2010). This model was used in a hybrid fashion in conjunction with three-dimensional models for the calculation of the necessary coefficients for the parameterization of the one-dimensional model.

Network for the one-dimensional modelling of a complex lock filling system (Thorenz 2010)

Summarizing one can say, that one-dimensional models are a very helpful tool for fast parameter studies in the design process. But it must be pointed out that the chosen parameter sets are a key factor for the results and thus must be evaluated with care.

2.4 Two-Dimensional Numerical Models

Two-dimensional numerical models are rarely used to model the lock filling process. Their main use case are computations of the far field in the inlet and outlet areas. Thus, further elaborations are omitted here.

2.5 Three-Dimensional Numerical Models

2.5.1 Overview

In the last two decades, three-dimensional numerical models have evolved from specialized tools which were only applicable for research purposes to a set of tools for engineering practice. Still the required knowledge level to achieve reliable results is high due to the high sensitivity of these models. In-depth knowledge of the numerical model is required in order to judge on the required grid and time step resolution, the used numerical schemes, the chosen turbulence and wall friction laws etc. The required computer power is acceptable today for local studies of the flow field, while still substantial computer power is required for more difficult questions. But for some aspects of the hydraulic design process, three-dimensional numerical modelling is no longer out of scope.

2.5.2 Local Models for Hybrid 1D-3D Approaches

Starting around 2010, the combination of three-dimensional models for the estimation of parameters with one-dimensional models for the filling system and/or the chamber became common (i.e. Roux et al. 2010, Thorenz 2010, Thorenz and Strybny 2012, O’Mahoney et al. 2018). This approach requires to set up detailed numerical models for all critical points in the filling system, where more complex geometric shapes make it difficult to predict the loss coefficients. Figure 3 presents a complex connection point, where flow from the lower left branch is distributed into the upper two branches. The time and space averaged results of this models can then be used to compute loss coefficients for a one-dimensional numerical model. For this type of models, the required computational resources are nowadays acceptable for engineering practice. Care must be taken for the choice of the turbulence model, an adequate grid resolution and sufficiently accurate numerical schemes.

2.5.3 Simplified Three-Dimensional Numerical Models for the Lock Chamber

Due to the complexity of modelling the complete locking process in a three-dimensional numerical model, it can be useful to limit the scope of the model. For example, it can be useful to compute the rate of flow into the chamber with a one-dimensional model and to use these results as a flowrate boundary condition in a three-dimensional model of the chamber (i.e. Roux et al. 2010, Verelst et al. 2018). Thus, the modelling of the moving valve and the feeding culverts would be omitted in the three-dimensional model. But it must be pointed out that this simplification comes with a price: The interaction between water motions in the lock chamber and the flowrate is broken by this approach. Thus, the dampening effect of the interaction between sloshing water and flowrate is not considered and the sloshing in the chamber can be overestimated for through-the-head systems.

Another feasible solution can be the simplification of the ship movement. If the vertical movement of the ship is small in relation to the under keel clearance, it can be favourable to use a stationary ship in the simulations. This reduces the computational complexity and costs significantly, but again comes with the price of a reduced accuracy. This approach can be a useful simplification for maritime locks with large water depth and small lift heights. A possible further simplification would be to omit the ship completely and just study the flow field and water level variations in the chamber (Stockstill 2009).

2.5.4 Full Three-Dimensional Models

The modelling of the complete locking process, including moving valves, the movement of the ship and of the water body from the upstream reach to the chamber is still a challenging task. It requires a significant understanding of the relevant hydraulic processes and of the required numerical modelling tools and allowable simplifications. Though some numerical models are seemingly able to produce results, these can be horribly wrong, even if they look plausible on the first glance. Thus, expert hydraulic knowledge is required to separate reasonable results from implausible ones.

When setting up full three-dimensional models for the lock filling process, the modeler should validate his toolchain and methodology first. This should be done by simulating a case for which the results are known from a physical model or from prototype data. While the simulation of the hydraulics (i.e. flow rates and water level development) is feasible today with reliable results, the reaction of the ship in terms of ship forces can be very hard to capture correctly. In Thorenz and Schulze (2021) a benchmark example is given, were a lock with a complex filling system was analysed both with a physical model and with a full three-dimensional model. The used validation datasets are freely available for further use. The example is presented in short form in Sect. 3.

2.5.5 Consideration of Density Currents and Air Entrainment

The modelling can be even more complicated, if the regarded fluid is not pure water, but is mixed with salt or air. The problem of mixing fresh and salt water occurs for locks in coastal regions. The salt can have a significant impact on the resulting ship forces, both during the filling process of the lock chamber and when opening the gates (Nogueira et al. 2018, Kortlever et al. 2018). This is due to the fact, that salt and fresh water do not mix immediately, but instead density currents are establishing in the lock chamber. These transport a higher momentum compared to currents under conditions with constant density. When filling a lock chamber, which was initially filled with saltwater, with freshwater, another not so obvious effect occurs: The freshwater can pool up in front of the bow of the vessel, while the saltwater remains behind the ship´s aft. In this situation the forces on the vessel can be quite high, even if the flow velocities are very low. This is solely due to the hydrostatic pressure difference between salt- and freshwater columns.

Within the three-dimensional numerical modelling, the salt is regarded as a tracer in the water, and as such is transported by advection and dispersion. But in contrast to a traditional tracer, it has an impact on the density of the water. A critical point can be the turbulence modelling. A stable stratification of salt and fresh water will reduce turbulent mixing, thus both the diffusion of salt and the spreading of momentum will be reduced. For an instable stratification, mixing and spreading of momentum will be increased instead. This must be considered in the model. It can either be incorporated in the turbulence model and in the transport equation for the salt or be accounted for by using a Large-Eddy-Simulation approach, to directly capture the behaviour of turbulence and salt transport in the large turbulent structures. An example for this is given in Thorenz (2019).

Generally, the entrainment of air is avoided when designing lock filling systems. But for locks with through-the-head systems it can be attractive from an economic point of view to use filling systems with valves which are located above the downstream water level. In that case, air entrainment is unavoidable. In numerical modelling, air entrainment is even more difficult to handle than salt transport. This has several reasons. First of all, the impact on the fluid density can be much bigger. Secondly, the movement of air in the water has a dynamic of its own, i.e. bubbles are rising to the surface. From a numerical point of view, several approaches exist. Models used in the chemical industry have very detailed physical representation of the bubble dynamics, but are limited to their scope. For the purpose described here, these models are not easily suitable. Recent research in hydraulic structures modelling are focused on simplifications of these models, in order to make them applicable for the flow around hydraulic structures. Schulze et al. (2018) showed simulations for a solver which incorporates air bubble movements and evaluated the impact on a ship in the chamber. Thorenz and Grefenstein (2022) recently compared a further model simplification with physical model results and evaluated the possible impact of entrained on the flow behind a weir.

3 Example for Full Three-Dimensional Modelling of the Locking Process

3.1 Introduction

The three-dimensional modelling of the complete lock filling process, including moving valves and floating ship, is still a daunting task due to its numerical requirements. It requires both substantial resources and specialist knowledge in hydraulics and the numerical tools. What makes things even worse is the fact, that numerical modelling toolboxes can produce accurate looking results, because the flow computed field looks plausible, even if the results are far from reality. On the other hand, the modelling process in terms of accurate ship forces is fragile, so the validation of the modelling methodology is obligatory. Basic requirements are the same as for the modelling of parts of the filling systems. Additionally, the dynamics of the ship must accurately be captured. A minimum requirement is the correct modelling of an initial calm period before opening the valves. In this period, which must last at least as long as the wave sloshing time in the chamber (e.g. 30 s–60 s), the modelled ship forces should be equal to zero in both longitudinal and transversal direction and the movements of the ship must be negligible. Practically the forces will be larger than zero due to inevitable numerical errors. In that case, the resulting non-zero forces must be compared to the acceptable errors for the simulations and, if too high, the model must be enhanced. Furthermore, it is necessary to analyse the recorded forces during the locking process. They should be evaluated in terms of the temporal development of the forces, which follows a typical pattern for each filling-system. In order to judge on the quantity of the forces, the modelling process should be validated with physical model data or prototype measurements. In the following a very short extract of the modelling and validation procedure as performed by Thorenz and Schulze (2021) is presented.

3.2 Model Setup

The regarded system is a navigation lock with a through-the-bottom filing system consisting of a large pressure chamber, fed by side culverts from lateral water saving basins and by culverts at the heads for the residual filling. Figure 4 presents a 3D-sketch of a part of the hydraulic system, showing only one of the three water saving basins. The culverts leading to the other water saving basins are cut at the valves.

For this setting a three-dimensional numerical model has been built based with the OpenFOAM® software package. The generated computational grid uses several areas of local refinements (e.g. at the valves, for the jet behind the valves, at the nozzles of the bottom filling system and for the jets in the chamber) and has 28 million computational cells. The numerical model was not calibrated in any way to fit to model data. Instead, the numerical approximation was performed as good as regarded as necessary by the modellers.

3.3 Assessment of Results

For the quality assessment of the numerical model, a physical scale model in 1:25 was available. A thorough comparison of numerical and physical model data was performed in order to judge on the quality of the numerical model (Thorenz and Schulze 2021). The comparison of flow rates and water levels showed a very good agreement between numerical and physical model. As expected, the impact of friction (i.e. roughness) was low in the numerical model (Fig. 5, roughness height is given in prototype scale).

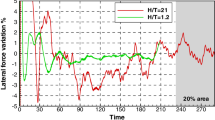

It must be pointed out that the flowrates cannot actually be measured in the physical model, but are computed from the chamber water level development. Thus, small deviations can be expected. The further evaluation of the longitudinal forces showed an excellent agreement with the physical model data (Fig. 6, again the roughness height is given in prototype scale). Please note that the height and shape of the first peak is most relevant and that the further development is of lower importance.

The comparison of the transversal forces showed the correct behaviour in terms of temporal development, but the absolute value was overestimated by the numerical model. Thorenz and Schulze (2021) present an analysis, where several possible causes are investigated. This includes also an analysis of possible errors in the physical model, because the analysis has also shown discrepancies between planned and realized physical model.

4 Conclusions

Over the last decades, numerical models have become a non-substitutable tool in the hydraulic design process for locks. Ranging from one-dimensional models, which can produce results almost immediately, to full blown three-dimensional models of the complete locking process, which will compute days on a cluster computer system, a large toolkit has been developed which can be used for a broad scope of analyses.

Analytical calculations, zero- and one-dimensional numerical models are seemingly simple, but they require to have calibration data available for the not resolved hydrodynamic processes. This data can be generated either by physical model runs or by three-dimensional numerical models for the regarded parts. To transfer it from one setup to a seemingly similar setup, expert knowledge is required. Based on the achieved parameterization, the lock filling process e.g. for different valve schedules can be quickly evaluated. This is a fast and appropriate method to evaluate significant parameters like filling time, ship force and flow velocities. But one must consider, that for these methods the results are strongly dependent on parameters which have to be evaluated with experiments or with models of higher complexity. Furthermore, more complex flow phenomena cannot be considered with these approaches.

Three dimensional models became more feasible over the last years. Unfortunately, even poor three-dimensional models will produce “realistic” looking results. Thus, professional experience is necessary to assess the results. The modeller should understand the expected hydraulic behaviour in order to judge on the qualitive results of the flow field. In correctly built three-dimensional numerical models, calibration of the model should not be necessary in most cases, as the only unknown quantity which is suitable for calibration is the wall friction, which is typically of lower importance. The quality of the modelling strategy is the most relevant factor to achieve reliable results. This includes the choice of a capable numerical model, an accurate representation of the geometry, choice and validation of turbulence models, suitable grid and timestep resolutions and the setup of the whole model in terms of physical correctness. Expert knowledge in numerical models is required to set up the models and expert knowledge in lock hydraulics is required to evaluate the quality of the results.

For the validation of any modelling methodology, it is necessary to test the modelling strategy first on a known case, before using it for an unknown setup. For the known testcase, the relevant data (i.e. flowrates and ship forces) should have been measured in a physical model or in a prototype. This offers the possibility to check the modelling methodology before applying it to other cases.

Summarizing one can say that numerical and physical modelling cannot replace expert knowledge. Models are only a tool, supporting professional work. A good compromise between accurate and economic engineering work can be reached with hybrid modelling, where different types of modelling approaches are combined.

References

Belzner F, Simons F, Thorenz C (2018) An application-oriented model for lock filling processes. In: Proceedings of the 34th PIANC-world congress, 7–11 May 2018, Panama City, Panama. https://henry.baw.de/handle/20.500.11970/107576

De Loor A, Weiler O, Kortlever W (2013) LOCKFILL: a mathematical model for calculating forces on a ship while levelling through the lock head. In: Proceedings of the PIANC SMART rivers conference. PIANC Association, Brussels

De Mulder T (2011) Computational fluid dynamics (CFD) in lock design: progress and challenges. In: “What’s new in the design of navigation locks” 2nd international workshop, PIANC - New-Orleans, 13–14 September 2011

Kortlever W, Van der Hout A, O’Mahoney T, de Loor A (2018) Levelling the new sea locks in the Netherlands: including the density difference. In: 34th PIANC world congress, Panama

Nogueira HIS, van der Ven P, O’Mahoney T, de Loor A, van der Hout A, Kortlever W (2018) Effect of density differences on the forces acting on a moored vessel while operating navigation locks. J Hydraul Eng 144(6)

O’Mahoney T, Heinsbroek A, De Loor A, Kortlever W Verelst K (2018) Numerical simulations of a longitudinal filling system for the new lock at Terneuzen. In: 34th PIANC world congress, Panama

PIANC (2015) InCom WG 155. Ship Behaviour in locks and lock approaches. Edited by PIANC, Brussels, Belgium

Roux S, Roumieu P, De Mulder T, Vantorre M, De Regge J, Wong J (2010) Determination of hawser forces using numerical and physical models for the third set of Panama locks studies. Paper 151 In: Proceeding of the PIANC MMX congress, Liverpool, UK, 10–14 May 2010

Schohl GA (1999) User’s manual for LOCKSIM: hydraulic simulation of navigation lock filling and emptying systems. Report CHL-99-1, U.S. Army Engineer WaterwaysExperiment Station, Vicksburg, USA

Schulze L, Stamm J, Thorenz C (2018) A new two-phase flow model for the investigation of the effect of entrained air in navigation locks. In: E-proceedings of the 38th IAHR world congress, 1–6 September 2019, Panama City, Panama

Stockstill R (2009) Computational model of a lock filling system. Report ERDC/CHL CHETN-IX-18, US Army Corps of Engineers

Thorenz C (2009) Computational fluid dynamics in lock design - state of the art. Paper 10, international workshop on “innovations in navigation lock design”, PIANC Brussels, 15–17 October 2009

Thorenz C (2010) Numerical evaluation of filling and emptying systems for the New Panama canal locks. In: Proceedings of the 32nd PIANC Congress 125th anniversary PIANC – setting the course, Liverpool, UK, 10–14 May 2010, Brussels, Belgium, pp 568–589

Thorenz C (2019) Can better turbulent mixing reduce density induced ship forces during lockage?. In: 34th PIANC world congress, Panama

Thorenz C, Grefenstein A (2022) Numerical modeling of air bubble transport behind a model scale weir. In: 39th IAHR world congress, 19–24 June 2022, Granada, Spain

Thorenz C, Strybny J (2012) On the numerical modelling of filling-emptying systems for lock. In: 10th international conference on hydroinformatics, HIC 2012, Hamburg, Germany

Thorenz C, Schulze L (2021) Numerical investigations of ship forces during lockage. J Coast Hydraul Struct. https://doi.org/10.48438/jchs.2021.0005

Verelst K, Vercruysse J, de Mulder T (2018) Comparison of software for computation of longitudinal forces on a ship in a lock chamber during levelling with openings in the lock gate. In: Bung, D, Tullis B (eds) 7th IAHR international symposium on hydraulic structures, Aachen, Germany, 15–18 May 2018. https://doi.org/10.15142/T3KD2H

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Thorenz, C., Belzner, F. (2023). On the Numerical Modelling of Ship Forces During Lockage. In: Li, Y., Hu, Y., Rigo, P., Lefler, F.E., Zhao, G. (eds) Proceedings of PIANC Smart Rivers 2022. PIANC 2022. Lecture Notes in Civil Engineering, vol 264. Springer, Singapore. https://doi.org/10.1007/978-981-19-6138-0_46

Download citation

DOI: https://doi.org/10.1007/978-981-19-6138-0_46

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-6137-3

Online ISBN: 978-981-19-6138-0

eBook Packages: EngineeringEngineering (R0)