Abstract

Since its first use to build sculptures, additive manufacturing has come a long way to become a prominent and prolific modern technology with wide acceptance due to significant benefits and advantages arising from its adoption and implementation in different industrial and consumer sectors. AM is rapidly paving a path towards an intensified technological society by facilitating unprecedented accomplishments ranging from digital storage of production data and on-demand manufacturing to repair and maintenance of malfunctioning machines, tools, and even human’s anatomy. This chapter presents a state-of-the-art review on the history and evolution of additive manufacturing technologies along with the emerging paradigm for the incorporation of AM in major industrial and research sectors. Overall, the chapter provides all the necessary insights essentially required by young researchers to understand where AM came from and where it is going.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- 2D:

-

Two-dimensional

- 3D:

-

Three-dimensional

- 4D:

-

Four-dimensional

- AM:

-

Additive Manufacturing

- ASTM:

-

American Society for Testing and Materials

- CAD:

-

Computer Aided Design

- CEN:

-

European Committee for Standardization

- CT:

-

Computer Tomography

- DED:

-

Directed Energy Deposition

- DMLS:

-

Direct Metal Laser Sintering

- EBM:

-

Electron Beam Melting

- FDM:

-

Fused Deposition Modelling

- HA:

-

Hydroxyapatite

- IOP:

-

Integrated Organ Printing

- IoT:

-

Internet of Things

- IP:

-

Intellectual Property

- ISO:

-

International Organization for Standardization

- LM:

-

Layered Manufacturing

- MRI:

-

Magnetic Resonance Imaging

- PEEK:

-

Polyether ether ketone

- RPD:

-

Rapid Plasma Deposition

- SLA:

-

Stereolithography

- SLS:

-

Selective Laser Sintering

- SMP:

-

Shape Memory Polymers

- UV:

-

Ultraviolet

References

Chua CK, Leong KF (2014) 3d printing and additive manufacturing: principles and applications (with companion media pack)—, 4th edn. World Scientific Publishing Company, Of Rapid Prototyping

Mannoor MS, Jiang Z, James T, Kong YL, Malatesta KA, Soboyejo WO, Verma N, Gracias DH, McAlpine MC (2013) 3D printed bionic ears. Nano Lett 13(6):2634–2639. https://doi.org/10.1021/nl4007744

Noor N, Shapira A, Edri R, Gal I, Wertheim L, Dvir T (2019) 3D printing of personalized thick and Perfusable cardiac patches and hearts. Adv Sci (Weinh) 6(11):1900344. https://doi.org/10.1002/advs.201900344

The history and application of additive manufacturing for design personalisation (2016). In: Kuksa I, Fisher T (ed) Design for Personalisation (1st ed.). Routledge. https://doi.org/10.4324/9781315576633

Bourell DL, Joseph J. Beaman J, Leu MC, Rosen DW (2009) A brief history of additive manufacturing and the 2009 roadmap for additive manufacturing: looking back and lookin ahead. US—Turkey workshop on rapid technologies, 5–11

D'Aveni R (2015) The 3-D printing revolution. harvard business review. https://hbr.org/2015/05/the-3-d-printing-revolution

Singh S, Ramakrishna S, Singh R (2017) Material issues in additive manufacturing: a review. J Manuf Process 25:185–200. https://doi.org/10.1016/j.jmapro.2016.11.006

Beaman JJ, Barlow JW, Bourell DL, Crawford RH, Marcus HL, McAlea KP (1997) Solid freeform fabrication: a new direction in manufacturing. Springer Science, Business Media, LLC.https://doi.org/10.1007/978-1-4615-6327-3

Sobieszek RA (2014) Sculpture as the sum of its profiles: François Willème and Photosculpture in France, 1859–1868. The Art Bulletin 62(4):617–630. https://doi.org/10.1080/00043079.1980.10787818

Baese C (1904) Photographic process for the production of plastic objects. US774549

Monteath FH (1924) Photomechanical process for producing bas reliefs. US1516199

Morioka I (1935) Process for manufacturing a relief by the aid of photography. US2015457

Morioka I (1944) Process for plastically reproducing objects. US2350796

Blanther JE (1892) Manufacture of contour relief maps. US473901

Perera BV (1940) Process of making relief maps. US2189592

Munz OJ (1956) Photo-glyph recording. US2775758

Zang EE (1964) Vitavue relief model technique. US3137080

Gaskin TA (1973) Earth science teaching device. US3751827

Swainson WK (1977) Method, medium and apparatus for producing three-dimensional figure product. US4041476

Woodin RL, Schwerzel RE, Kaldor A, Wood VE, McGinniss VD, Verber CM (1984) Three-dimensional photochemical machining with lasers. Paper presented at the applications of lasers to industrial chemistry

Matsubara K (1974) Molding method of casting using Photocurable substance. Jpn Kokai Patent Appl Patent Sho 51[1976]-10813

Ciraud PA (1972) Process and device for the manufacture of any objects desired from any meltable material. FRG Disclosure Publication 2263777

Householder RF (1981) Molding process. US4247508

DiMatteo PL (1976) Method of generating and constructing three-dimensional bodies. US3932923

Nakagawa T (1979) Blanking tool by stacked bainite steel plates. Press Technique, pp 93–101

Kunieda M, Nakagawa T (1984) Development of laminated drawing dies by laser cutting. Bull of JSPE, pp 353–354

Nakagawa T (1985) Laser cut sheet laminated forming dies by diffusion bonding. Proc 25th MTDR Conf, pp 505–510

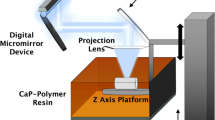

Zheng X, Deotte J, Alonso MP, Farquar GR, Weisgraber TH, Gemberling S, Lee H, Fang N, Spadaccini CM (2012) Design and optimization of a light-emitting diode projection micro-stereolithography three-dimensional manufacturing system. Rev Sci Instrum 83(12):125001. https://doi.org/10.1063/1.4769050

Herbert AJ (1982) Solid Object Generation Jour Appl Photo Eng 8(4):185–188

Hull CW (1986) Apparatus for production of three-dimensional objects by stereolithography US4575330

Wohlers T, Gornet T (2016) History of additive manufacturing

Sachs EM, Haggerty JS, Cima MJ, Williams PA (1993) Three-dimensional printing techniques. US5204055

ASTM (2015) Standard terminology for additive manufacturing—general principles. Part 1: terminology ISO/ASTM Stand. 52792

Sprinkle T The 5 most important standards in additive manufacturing. https://sn.astm.org/?q=features/5-most-important-standards-additive-manufacturing-.html

Holzl K, Lin S, Tytgat L, Van Vlierberghe S, Gu L, Ovsianikov A (2016) Bioink properties before, during and after 3D bioprinting. Biofabrication 8(3):032002. https://doi.org/10.1088/1758-5090/8/3/032002

Yu Y (2014) Ozbolat IT Tissue strands as “bioink” for scale-up organ printing. In: 2014 36th annual international conference of the IEEE engineering in medicine and biology society, 26–30 Aug. 2014 2014, pp 1428–1431. doi:https://doi.org/10.1109/EMBC.2014.6943868

Zhao Y, Li Y, Mao S, Sun W, Yao R (2015) The influence of printing parameters on cell survival rate and printability in microextrusion-based 3D cell printing technology. Biofabrication 7(4):045002. https://doi.org/10.1088/1758-5090/7/4/045002

Derakhshanfar S, Mbeleck R, Xu K, Zhang X, Zhong W, Xing M (2018) 3D bioprinting for biomedical devices and tissue engineering: a review of recent trends and advances. Bioact Mater 3(2):144–156. https://doi.org/10.1016/j.bioactmat.2017.11.008

Knowlton S, Onal S, Yu CH, Zhao JJ, Tasoglu S (2015) Bioprinting for cancer research. Trends Biotechnol 33(9):504–513. https://doi.org/10.1016/j.tibtech.2015.06.007

Daly AC, Cunniffe GM, Sathy BN, Jeon O, Alsberg E, Kelly DJ (2016) 3D Bioprinting of developmentally inspired templates for whole bone organ engineering. Adv Healthc Mater 5(18):2353–2362. https://doi.org/10.1002/adhm.201600182

Kesti M, Eberhardt C, Pagliccia G, Kenkel D, Grande D, Boss A, Zenobi-Wong M (2015) Bioprinting complex cartilaginous structures with clinically compliant biomaterials. Adv Func Mater 25(48):7406–7417. https://doi.org/10.1002/adfm.201503423

Pati F, Jang J, Ha DH, Won Kim S, Rhie JW, Shim JH, Kim DH, Cho DW (2014) Printing three-dimensional tissue analogues with decellularized extracellular matrix bioink. Nat Commun 5:3935. https://doi.org/10.1038/ncomms4935

Schmolka IR (1972) Artificial skin 1. Preparation and properties of pluronic F-127 gels for treatment of burns. J Biomed Mater Res 6:571–582

Merceron TK, Burt M, Seol YJ, Kang HW, Lee SJ, Yoo JJ, Atala A (2015) A 3D bioprinted complex structure for engineering the muscle-tendon unit. Biofabrication 7(3):035003. https://doi.org/10.1088/1758-5090/7/3/035003

Binder KW (2011) In situ bioprinting of the skin

Zhang YS, Yue K, Aleman J, Moghaddam KM, Bakht SM, Yang J, Jia W, Dell’Erba V, Assawes P, Shin SR, Dokmeci MR, Oklu R, Khademhosseini A (2017) 3D Bioprinting for tissue and organ fabrication. Ann Biomed Eng 45(1):148–163. https://doi.org/10.1007/s10439-016-1612-8

Mironov V, Prestwich G, Forgacs G (2007) Bioprinting living structures. J Mater Chem 17(20). https://doi.org/10.1039/b617903g

Gaebel R, Ma N, Liu J, Guan J, Koch L, Klopsch C, Gruene M, Toelk A, Wang W, Mark P, Wang F, Chichkov B, Li W, Steinhoff G (2011) Patterning human stem cells and endothelial cells with laser printing for cardiac regeneration. Biomaterials 32(35):9218–9230. https://doi.org/10.1016/j.biomaterials.2011.08.071

Nahmias Y, Odde DJ (2006) Micropatterning of living cells by laser-guided direct writing: application to fabrication of hepatic–endothelial sinusoid-like structures. Nat Protoc 1(5):2288–2296. https://doi.org/10.1038/nprot.2006.386

Lu Y, Mapili G, Suhali G, Chen S, Roy K (2006) A digital micro-mirror device-based system for the microfabrication of complex, spatially patterned tissue engineering scaffolds. J Biomed Mater Res A 77(2):396–405. https://doi.org/10.1002/jbm.a.30601

Mehla S, Kandjani A, Coyle V, Harrison CJ, Low MX, Kaner RB, Sabri Y, Bhargava SK (2022) Gold sunflower microelectrode arrays with dendritic nanostructures on the lateral surfaces for antireflection and surface-enhanced Raman scattering. ACS Appl. Nano Mater. 5(2):1873–1890.https://doi.org/10.1021/acsanm.1c03501

Therriault D, White SR, Lewis JA (2003) Chaotic mixing in three-dimensional microvascular networks fabricated by direct-write assembly. Nat Mater 2(4):265–271. https://doi.org/10.1038/nmat863

Wu W, DeConinck A, Lewis JA (2011) Omnidirectional printing of 3D microvascular networks. Adv Mater 23(24):H178-183. https://doi.org/10.1002/adma.201004625

Kolesky DB, Homan KA, Skylar-Scott MA, Lewis JA (2016) Three-dimensional bioprinting of thick vascularized tissues. Proc Natl Acad Sci U S A 113(12):3179–3184. https://doi.org/10.1073/pnas.1521342113

Yan Q, Dong H, Su J, Han J, Song B, Wei Q, Shi Y (2018) A Review of 3D printing technology for medical applications. Engineering 4(5):729–742. https://doi.org/10.1016/j.eng.2018.07.021

Hager I, Golonka A, Putanowicz R (2016) 3D printing of buildings and building components as the future of sustainable construction? Procedia Engineering 151:292–299. https://doi.org/10.1016/j.proeng.2016.07.357

Sakin M, Kiroglu YC (2017) 3D printing of buildings: construction of the sustainable houses of the future by BIM. Energy Procedia 134:702–711

Lloret E, Shahab AR, Linus M, Flatt RJ, Gramazio F, Kohler M, Langenberg S (2015) Complex concrete structures. Comput Aided Des 60:40–49. https://doi.org/10.1016/j.cad.2014.02.011

Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos B Eng 143:172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

Tay YWD, Panda B, Paul SC, Noor Mohamed NA, Tan MJ, Leong KF (2017) 3D printing trends in building and construction industry: a review. Virt Phys Prototyping 12(3):261–276. https://doi.org/10.1080/17452759.2017.1326724

Xia M, Sanjayan J (2016) Method of formulating geopolymer for 3D printing for construction applications. Mater Des 110:382–390. https://doi.org/10.1016/j.matdes.2016.07.136

Mueller S, Mohr T, Guenther K, Frohnhofen J, Baudisch P (2014) faBrickation. Paper presented at the proceedings of the SIGCHI conference on human factors in computing systems

Severini C. http://printinthemix.cad.rit.edu/Research/Show/127

Sun J, Zhou W, Huang D, Fuh JYH, Hong GS (2015) An overview of 3D printing technologies for food fabrication. Food Bioprocess Technol 8(8):1605–1615. https://doi.org/10.1007/s11947-015-1528-6

Liu Z, Zhang M, Bhandari B, Wang Y (2017) 3D printing: printing precision and application in food sector. Trends Food Sci Technol 69:83–94. https://doi.org/10.1016/j.tifs.2017.08.018

Chen Z (2016) Research on the impact of 3D printing on the international supply Chain. Adv Mater Sci Eng 2016:1–16. https://doi.org/10.1155/2016/4173873

Jia F, Wang X, Mustafee N, Hao L (2016) Investigating the feasibility of supply chain-centric business models in 3D chocolate printing: a simulation study. Technol Forecast Soc Chang 102:202–213. https://doi.org/10.1016/j.techfore.2015.07.026

Payne CLR, Dobermann D, Forkes A, House J, Josephs J, McBride A, Müller A, Quilliam RS, Soares S (2016) Insects as food and feed: European perspectives on recent research and future priorities. J Insects Food Feed 2(4):269–276. https://doi.org/10.3920/JIFF2016.0011

Vancauwenberghe V, Baiye Mfortaw Mbong V, Vanstreels E, Verboven P, Lammertyn J, Nicolai B (2019) 3D printing of plant tissue for innovative food manufacturing: encapsulation of alive plant cells into pectin based bio-ink. J Food Eng 263:454–464. https://doi.org/10.1016/j.jfoodeng.2017.12.003

Sun J, Peng Z, Zhou W, Fuh JYH, Hong GS, Chiu A (2015) A review on 3D printing for customized food fabrication. Procedia Manuf 1:308–319. https://doi.org/10.1016/j.promfg.2015.09.057

Pallottino F, Hakola L, Costa C, Antonucci F, Figorilli S, Seisto A, Menesatti P (2016) Printing on food or food printing: a review. Food Bioprocess Technol 9(5):725–733. https://doi.org/10.1007/s11947-016-1692-3

Yang F, Zhang M, Bhandari B (2017) Recent development in 3D food printing. Crit Rev Food Sci Nutr 57(14):3145–3153. https://doi.org/10.1080/10408398.2015.1094732

Lipson H, Kurman M (2013) Fabricated: the new world of 3D printing. Wiley

Masuch T A world first: additively manufactured titanium components now onboard the Airbus A350 XWB. https://www.etmm-online.com/a-world-first-additively-manufactured-titanium-components-now-onboard-the-airbus-a350-xwb-a-486310/

Wimpenny DI, Pandey PM, Kumar LJ (2017) Advances in 3D printing & additive manufacturing technologies

Khajavi SH, Partanen J, Holmström J (2014) Additive manufacturing in the spare parts supply chain. Comput Ind 65(1):50–63. https://doi.org/10.1016/j.compind.2013.07.008

SpaceX—Capabilities & Services. https://www.spacex.com/media/Capabilities&Services.pdf

Zhang Q, Zhang K, Hu G (2016) Smart three-dimensional lightweight structure triggered from a thin composite sheet via 3D printing technique. Sci Rep 6:22431. https://doi.org/10.1038/srep22431

Hong S, Sycks D, Chan HF, Lin S, Lopez GP, Guilak F, Leong KW, Zhao X (2015) 3D printing of highly stretchable and tough hydrogels into complex. Cellularized Structures. Adv Mater 27(27):4035–4040. https://doi.org/10.1002/adma.201501099

Wehner M, Truby RL, Fitzgerald DJ, Mosadegh B, Whitesides GM, Lewis JA, Wood RJ (2016) An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 536(7617):451–455. https://doi.org/10.1038/nature19100

Yu K, Ge Q, Qi HJ (2014) Reduced time as a unified parameter determining fixity and free recovery of shape memory polymers. Nat Commun 5:3066. https://doi.org/10.1038/ncomms4066

Zhao Q, Qi HJ, Xie T (2015) Recent progress in shape memory polymer: nw behavior, enabling materials, and mechanistic understanding. Prog Polym Sci 49–50:79–120. https://doi.org/10.1016/j.progpolymsci.2015.04.001

Choi J, Kwon OC, Jo W, Lee HJ, Moon M-W (2015) 4D printing technology: a review. 3D Printing Addit Manuf 2(4):159–167. https://doi.org/10.1089/3dp.2015.0039

Tibbits S, McKnelly C, Olguin C, Dikovsky D, Hirsch S 4D printing and univerrsal transformation. In, 2014

Jung JP, Bhuiyan DB, Ogle BM (2016) Solid organ fabrication: comparison of decellularization to 3D bioprinting. Biomater Res 20(1):27. https://doi.org/10.1186/s40824-016-0074-2

Zarek M, Mansour N, Shapira S, Cohn D (2017) 4D printing of shape memory-based personalized Endoluminal medical devices. Macromol Rapid Commun 38 (2). https://doi.org/10.1002/marc.201600628

Taylor DL, In Het Panhuis M (2016) Self-healing hydrogels. Adv Mater 28(41):9060–9093. https://doi.org/10.1002/adma.201601613

Khoo ZX, Teoh JEM, Liu Y, Chua CK, Yang S, An J, Leong KF, Yeong WY (2015) 3D printing of smart materials: a review on recent progresses in 4D printing. Virt Phys Prototyping 10(3):103–122. https://doi.org/10.1080/17452759.2015.1097054

Jiang R, Kleer R, Piller FT (2017) Predicting the future of additive manufacturing: a Delphi study on economic and societal implications of 3D printing for 2030. Technol Forecast Soc Chang 117:84–97. https://doi.org/10.1016/j.techfore.2017.01.006

Agarwal T, Hann SY, Chiesa I, Cui H, Celikkin N, Micalizzi S, Barbetta A, Costantini M, Esworthy T, Zhang LG, De Maria C, Maiti TK (2021) 4D printing in biomedical applications: emerging trends and technologies. J Mater Chem B 9(37):7608–7632. https://doi.org/10.1039/d1tb01335a

Momeni F, Mehdi Hassani MNS, Liu X, Ni J (2017) A review of 4D printing. Mater Design 122:42–79.https://doi.org/10.1016/j.matdes.2017.02.068

Kamila, (2013) Introduction, classification and applications of smart materials: an overview. Am J Appl Sci 10(8):876–880. https://doi.org/10.3844/ajassp.2013.876.880

Vaezi M, Chianrabutra S, Mellor B, Yang S (2013) Multiple material additive manufacturing—Part 1: a review. Virt Phys Prototyping 8(1):19–50. https://doi.org/10.1080/17452759.2013.778175

Mitchell A, Lafont U, Hołyńska M, Semprimoschnig C (2018) Additive manufacturing—a review of 4D printing and future applications. Addit Manuf 24:606–626. https://doi.org/10.1016/j.addma.2018.10.038

Shin D-G, Kim T-H, Kim D-E (2017) Review of 4D printing materials and their properties. Int J Precis Eng Manuf Green Technol 4(3):349–357. https://doi.org/10.1007/s40684-017-0040-z

Yang W, Lu H, Huang W, Qi H, Wu X, Sun K (2014) Advanced shape memory technology to reshape product design. Manuf Recycling. Polymers 6(8):2287–2308. https://doi.org/10.3390/polym6082287

Ramakrishna S, Mayer J, Wintermantel E, Leong KW (2001) Bomedical applications of polymer-composite materials: a review. Compos Sci Technol 61:1189

Stavropoulos P, Foteinopoulos P, Papacharalampopoulos A, Bikas H (2018) Addressing the challenges for the industrial application of additive manufacturing: towards a hybrid solution. Int J Lightweight Mater Manuf 1(3):157–168. https://doi.org/10.1016/j.ijlmm.2018.07.002

Wohlers Report 2012

Franke N, Piller F (2004) Value creation by toolkits for user innovation and design: the case of the watch market. J Product Innov Manag 21:401–415

Lott P, Schleifenbaum H, Meiners W, Wissenbach K, Hinke C, Bültmann J (2011) Design of an optical system for the in situ process monitoring of selective laser melting (SLM). Phys Procedia 12:683–690. https://doi.org/10.1016/j.phpro.2011.03.085

P R (2009) Additive manufacturing–a supply chain wide response to economic uncertainty and en-vironmental sustainability. In: Mass customization engineering and managing global operations

Huang SH, Liu P, Mokasdar A, Hou L (2012) Additive manufacturing and its societal impact: a literature review. Int J Adv Manuf Technol 67(5–8):1191–1203. https://doi.org/10.1007/s00170-012-4558-5

du Plessis A, Broeckhoven C, Yadroitsava I, Yadroitsev I, Hands CH, Kunju R, Bhate D (2019) Beautiful and functional: a review of biomimetic design in additive manufacturing. Addit Manuf 27:408–427. https://doi.org/10.1016/j.addma.2019.03.033

Beyers RN, Blignaut AS, Mophuti L (2012) Mobile fablabs: local and rural innovation in South Africa. In: EdMedia+ innovate learning association for the advancement of computing in education (AACE), pp 112–122

Ishengoma FR, Mtaho AB (2014) 3D Printing: developing counties perspectives. Int J Comput Appl 104(11)

Berman B (2012) 3-D printing: the new industrial revolution. Bus Horiz 55(2):155–162. https://doi.org/10.1016/j.bushor.2011.11.003

Loh GH, Pei E, Harrison D, Monzón MD (2018) An overview of functionally graded additive manufacturing. Addit Manuf 23:34–44. https://doi.org/10.1016/j.addma.2018.06.023

Oxman N (2011) Variable property rapid prototyping. Virt Phys Prototyping 6(1):3–31. https://doi.org/10.1080/17452759.2011.558588

Junk S, Sämann-Sun J, Niederhofer M (2010) Application of 3D printing for the rapid tooling of thermoforming moulds. In: Proceedings of the 36th international MATADOR conference Springer, London, pp 369–372

Wang PH, Kim G, Sterkenburg R (2019) Investigating the effectiveness of a 3D printed composite mold. Int Schol Scient Res Innov 13(11):684–688

Kumar K, Zindani D, Davim JP (2020) Rapid prototyping, rapid tooling and reverse engineering: from biological models to 3D Bioprinters. De Gruyter. https://doi.org/10.1515/9783110664904

D HP (2000) Rapid tooling: technologies and industrial applications

T C (2015) Wohlers Report 2015: additive manufacturing and 3D printing state of the industry annual worldwide progress report

Mehla S, Kandjani AE, Babarao R, Lee AF, Periasamy S, Wilson K, Ramakrishna S, Bhargava SK (2021) Porous crystalline frameworks for thermocatalytic CO2 reduction: an emerging paradigm. Energy Environ Sci 14(1):320–352. https://doi.org/10.1039/d0ee01882a

Zhakeyev A, Wang P, Zhang L, Shu W, Wang H, Xuan J (2017) Additive manufacturing: unlocking the evolution of energy materials. Adv Sci 4(10):1700187. https://doi.org/10.1002/advs.201700187

Mehla S, Kukade S, Kumar P, Rao PVC, Sriganesh G, Ravishankar R (2019) Fine tuning H-transfer and β-scission reactions in VGO FCC using metal promoted dual functional ZSM-5. Fuel 242:487–495. https://doi.org/10.1016/j.fuel.2019.01.065

Nishiyama H, Yamada T, Nakabayashi M, Maehara Y, Yamaguchi M, Kuromiya Y, Nagatsuma Y, Tokudome H, Akiyama S, Watanabe T, Narushima R, Okunaka S, Shibata N, Takata T, Hisatomi T, Domen K (2021) Photocatalytic solar hydrogen production from water on a 100-m(2) scale. Nature 598(7880):304–307. https://doi.org/10.1038/s41586-021-03907-3

Mehla S, Krishsna V, Sriganesh G, Ravishankar R (2018) Mesoporous superacid catalysts for valorisation of refinery naphtha stream. RSC Adv 8(59):33702–33709. https://doi.org/10.1039/C8RA07024E

Path to hydrogen competitiveness: a cost perspective (2020). Hydrogen Council

Silveria GD, Borenstein D, Fogliatto FS (2001) Mass customization: literature review and research direction. Int J Product Econ 72:1–13

Mai J, Zhang L, Tao F, Ren L (2015) Customized production based on distributed 3D printing services in cloud manufacturing. Int J Adv Manuf Technol 84(1–4):71–83. https://doi.org/10.1007/s00170-015-7871-y

Liu N, Choi T-M, Yuen C-WM, Ng F (2012) Optimal pricing, modularity, and return policy under mass customization. IEEE Trans Syst Man Cybern Part A: Syst Hum 42(3):604–614. https://doi.org/10.1109/tsmca.2011.2170063

Hart CWL (1994) Mass customization: conceptual underpinnings, opportunities and limits. Int J Serv Ind Manag 6(2):36–45

Quinlan HE, Hasan T, Jaddou J, Hart AJ (2017) Industrial and consumer uses of additive manufacturing: a discussion of capabilities, trajectories, and challenges. J Ind Ecol 21(S1):S15–S20. https://doi.org/10.1111/jiec.12609

Salvador F, Forza C, Rungtusanatham M (2002) Modularity, product variety, production volume, and component sourcing: theorizing beyond generic prescriptions. J Oper Manag 20(5):549–575. https://doi.org/10.1016/S0272-6963(02)00027-X

Hu SJ (2013) Evolving paradigms of manufacturing: from mass production to mass customization and personalization. Procedia CIRP 7:3–8. https://doi.org/10.1016/j.procir.2013.05.002

Acher M, Baudry B, Barais O, Jézéquel J-M (2014) Customization and 3D printing. Paper presented at the proceedings of the 18th international software product line conference, Vol 1

Banks J (2013) Adding value in additive manufacturing: researchers in the United Kingdom and Europe look to 3D printing for customization. IEEE Pulse 4(6):22–26. https://doi.org/10.1109/MPUL.2013.2279617

Kyriakou H, Nickerson JV, Sabnis G (2017) Knowledge reuse for customization: Metamodels in an open design community for 3D printing. MIS Q 41(1):315–332

Qiu J, Gao Q, Zhao H, Fu J, He Y (2017) Rapid Customization of 3D integrated microfluidic chips via modular structure-based design. ACS Biomater Sci Eng 3(10):2606–2616. https://doi.org/10.1021/acsbiomaterials.7b00401

Mehla S, Das J, Jampaiah D, Periasamy S, Nafady A, Bhargava SK (2019) Recent advances in preparation methods for catalytic thin films and coatings. Catal Sci Technol 9:3582–3602. https://doi.org/10.1039/C9CY00518H

Groeger D, Chong Loo E, Steimle J (2016) HotFlex. Paper presented at the Proceedings of the 2016 CHI conference on human factors in computing systems

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Singh, S., Mehla, S., Bhargava, S.K., Ramakrishna, S. (2022). History and Evolution of Additive Manufacturing. In: Bhargava, S.K., Ramakrishna, S., Brandt, M., Selvakannan, P. (eds) Additive Manufacturing for Chemical Sciences and Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-2293-0_2

Download citation

DOI: https://doi.org/10.1007/978-981-19-2293-0_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-2292-3

Online ISBN: 978-981-19-2293-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)