Abstract

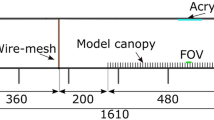

Air-assisted spray technology can increase the droplet deposition rate and reduce droplet drift. In order to broaden the transport channel of droplets, the effect of wind speed on the dynamic change of static porosity of crop canopy was studied. Taking cotton as an example, we established four simulated cotton plants and measured the wind speed in the canopy. Through the numerical calculation of the windward area, airflow speed and leaf parameters, the change of leaf inclination in the stratified zoning is determined when the leaves are affected by different airflow speeds. Finally, numerical results of static porosity changes in different regions are obtained. The results show that the static porosity model can be used to calculate the dynamic porosity.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Duga, A.T., Dekeyser, D., Ruysen, K., et al.: Numerical analysis of the effects of wind and sprayer type on spray distribution in different orchard training systems. Bound. Layer Meteorol. 157(3), 517–535 (2015)

Miranda-Fuentes, A., Rodríguez-Lizana, A., Gil, E., et al.: Influence of liquid-volume and airflow rates on spray application quality and homogeneity in super-intensive olive tree canopies. Sci. Total Environ. 537, 250–259 (2015)

Li, J., Shi, Y., Lan, Y., et al.: Vertical distribution and vortex structure of rotor wind field under the influence of rice canopy. Comput. Electron. Agric. 159, 140–146 (2019)

Hong, S., Zhao, L., Zhu, H.: CFD simulation of airflow inside tree canopies discharged from air-assisted sprayers. Comput. Electron. Agric. 149, 121–132 (2018)

Hong, S., Zhao, L., Zhu, H.: CFD simulation of pesticide spray from air-assisted sprayers in an apple orchard: tree deposition and off-target losses. Atmos. Environ. 175, 109–119 (2018)

Liu, X., Liu, X., Li, Y., et al.: Estimation model of canopy stratification porosity based on morphological characteristics: a case study of cotton. Biosys. Eng. 193, 174–186 (2020)

Liu, X., Liu, X., Li, Y., et al.: Predicting spray deposit distribution within a cotton plant canopy based on canopy stratification porosity and Gaussian process models. Biosys. Eng. 204, 1–14 (2021)

Liu, X., Yuan, J., Li, Y., et al.: Deformation modelling of cotton leaf under assisted airflow using bidirectional fluid-structure coupling method. Trans. CSAE 37(5), 68–76 (2021)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (52075308).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Liu, Y., Cui, H., Liu, X., Liu, X. (2022). Dynamic Porosity Estimation Model Based on Wind Speed Variation in Cotton Canopy. In: Wang, Y., Martinsen, K., Yu, T., Wang, K. (eds) Advanced Manufacturing and Automation XI. IWAMA 2021. Lecture Notes in Electrical Engineering, vol 880. Springer, Singapore. https://doi.org/10.1007/978-981-19-0572-8_79

Download citation

DOI: https://doi.org/10.1007/978-981-19-0572-8_79

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-0571-1

Online ISBN: 978-981-19-0572-8

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)