Abstract

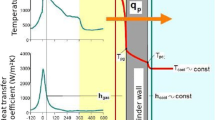

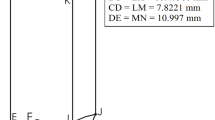

An accurate model for the heat release rate in a modern DI diesel engine is newly evolved from the known mixing-controlled combustion model. In this chapter, the combustion rate is precisely described by relating the mixing rate to the turbulent energy created at the exit of the nozzle as a function of the injection velocity and by considering the dissipation of energy in free air and along the wall. The complete absence of tuning constants distinguishes the model from the other zero-dimensional or pseudo-multi-dimensional models, at the same time retaining the simplicity. Successful prediction of the history of heat release in engines widely varying in bores, rated speeds, and types of aspiration, at all operating conditions, validated the model. The earlier model has explained correctly the effect of the kinetic energy of fuel injection. However, it considered only the spray in the air and the accuracy of prediction was only about 65%. In most of the engines of bore less than 130 mm, wall jet plays a very important role. By considering the wall jet in detail, the heat release has been explained to an accuracy better than 95%. This was proved for a variety of engines. The bores range from 85 to 280 mm.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- n :

-

Engine speed (rpm)

- 1/ρf dmf/dθ:

-

Volumetric injection rate injection of fuel (m3/crank degree)

- a and b:

-

Engine-specific constants for the rate of burning (−)

- AFRstoich:

-

Air–fuel ratio for the stoichiometric combustion of diesel (−)

- A n :

-

Area of nozzle holes (m2)

- A s :

-

Instantaneous surface area (m2)

- C d :

-

Coefficient of discharge of the nozzle (−)

- C diss :

-

Dissipation constant = 0.01 (s−1)

- C model :

-

A model constant, 1000 (kJ/kg/deg)

- C rate :

-

Constant for mixing rate, 0.002 (s)

- C turb :

-

Efficiency of conversion of kinetic energy to turbulence energy in free jet = 0.2 (−)

- d e :

-

Equivalent diameter of the orifice (m)

- dE diss /dθ :

-

Rate of energy dissipation across the control surface (J/s)

- dE i /dθ :

-

Rate of the generation of the kinetic energy of fuel jet into the cylinder (J/s)

- dm b /dt :

-

Rate of burning (kg/s)

- dQ/dθ :

-

Rate of heat release (J/s)

- E u :

-

Total turbulent kinetic energy of fuel jet at a given crank angle instant (J)

- f 1 :

-

A function of fuel availability (−)

- f 2 :

-

A function of fuel–air mixing (−)

- h c :

-

Heat transfer coefficient (W/(m2K))

- k :

-

Density of turbulent kinetic energy (J/m3)

- LCV:

-

Lower calorific value of fuel (J/kg)

- m b :

-

Cumulative mass of fuel burnt (kg)

- m f :

-

Cumulative mass of fuel injected (kg)

- n p :

-

Piston velocity (m/s)

- Q :

-

Cumulative heat release (J)

- s :

-

Penetration of spray (m)

- t :

-

Time after the start of injection (s)

- T g :

-

Cylinder charge temperature (K)

- T o :

-

Reference temperature, 294 (K)

- T surr :

-

Surrounding temperature (K)

- T w :

-

Wall temperature (K)

- U j :

-

Velocity of fuel jet at the exit of the nozzle (m/s)

- V :

-

Instantaneous cylinder volume (m3)

- V :

-

Instantaneous cylinder volume (m3)

- λ diff :

-

Air excess ratio for diffusion combustion (−)

- ρ f :

-

Density of fuel (kg/m3)

References

Austen AEW, Lyn WT (1960) Relation between fuel injection and heat release in a direct-injection engine and the nature of the combustion process. In: Proceedings of the Institute of Mechanical Engineers

Watson N, Pilley AD, Marzauk M (1980) A combustion correlation for diesel engine simulation. SAE 800029

Shahed SM, Chiu WS, Yumlu VS (1978) A preliminary model for the formation of nitric oxides in DI diesel engine and its application in parametric studies. SAE 730083

Dent JC, Mehta PS (1981) Phenomenological combustion model for a quiescent chamber diesel engine. SAE 811235

Hiroyasu H et al (1983) Development and use of spray combustion modelling to predict diesel engine efficiency and pollutant emissions. Bull JSME 26(214)

Cartillieri W, Johns RJR (1983) Multidimensional modeling of engine processes: progress and prospects. Fifteenth CIMAC Congress, Paris

Gosman AD, Tsui YY, Watkins AP (1985) calculation of unsteady three-dimensional flow in a model motored reciprocating engine and comparison with experiment. In: Fifth International Turbulent Shear Flow Meeting, Cornell University

Chmela FG, Orthaber GC (1999) Rate of heat release prediction for a direct injection diesel engine based on purely mixing controlled combustion. SAE 99010186

Lakshminarayanan PA, Aghav YV, Dani AD Mehta PS (2002) Accurate prediction of the rate of heat release in a modern direct injection diesel engine. IMechE, 216, J Automobile

Lakshminarayanan PA, Nagpurkar UP (1986) Rate of heat release for the divided combustion chamber. SAE 860084

Magnussen BF and Hjertager BH (1976) On mathematical modelling of turbulent combustion with special emphasis on soot formation and combustion. In: International symposium on combustion

Heywood JB (1988) A textbook on Internal Combustion engine fundamentals. McGraw-Hill International Edition

Hohenberg GH (1979) Advance approach for heat transfer calculation. SAE 790825

Gajendra Babu MK, Murthy BS (1976) Simulation and evaluation of Exhaust and Intake system of a 4-stroke spark-ignition Engine. SAE 760:763

Lakshminarayanan PA, Dent JC (1983) Interferometric studies of vapourising and combusting sprays. SAE 830244

Weibe II (1970) Brennverlauf und Kreisprozeb von Verbrennungsmotoren. VEB Verlag Technik, Berlin

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Lakshminarayanan, P.A., Aghav, Y.V. (2022). Heat Release in Direct Injection Engines. In: Modelling Diesel Combustion. Mechanical Engineering Series. Springer, Singapore. https://doi.org/10.1007/978-981-16-6742-8_9

Download citation

DOI: https://doi.org/10.1007/978-981-16-6742-8_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-6741-1

Online ISBN: 978-981-16-6742-8

eBook Packages: EngineeringEngineering (R0)