Abstract

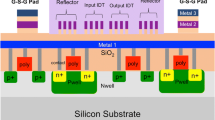

Zinc oxide (ZnO) is a multifunctional material and flaunts optical, piezoelectric and semiconducting properties. ZnO thin film, as a basic layer, is used in micro-electro-mechanical systems (MEMS)-based devices for sensing and actuation purpose. ZnO-based micro-electro-mechanical structures such as cantilevers and membranes require single-side processing of Si wafer. Dry etching process (DRIE) is desired way to etch silicon. Preferably, wet chemicals like potassium hydroxide (KOH), ethylene diamine pyrochatechol (EDP) or tetramethylammonium hydroxide (TMAH) can also be used to etch silicon in a more economical way. However, ZnO film is not amicable to such chemicals and dissolves in no time. Therefore, the protection of ZnO thin film in etching solvent is a very crucial issue while releasing this kind of structures. The chapter presents silicon wet etching experiments in tetramethylammonium hydroxide (TMAH) solution using silicon-based organic polymer as a protective mask for the zinc oxide sputtered side of wafer since it is difficult to use and remove SiO2 or Si3N4 as an etching barrier, in multilayer structures. A comprehensive characterization of ZnO thin film is performed to demonstrate that structural, mechanical and electrical properties of thin film remain unaltered.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ozgur U, Alivov Y, Liu C, Teke A, Reshchikov MA, Dogan S, Avrutin V, Cho SJ, Morkoc H (2005) A comprehensive review of ZnO materials and devices. J Appl Phys 98:041301

Fu YQ, Luo JK, Du XY, Flewitt AJ, Li Y, Markx GH, Walton AJ, Milne WI (2010) Recent developments on ZnO films for acoustic wave based bio-sensing and microfluidic applications: a review. Sens Actuat B 143:606

Baraki R, Novak N, Fromling T, Granzow T, Rodel J (2014) Bulk ZnO as piezotronic pressure sensor. App Phys Lett 105:111604

DeVoe DL, Pisano AP (2001) Surface micromachined piezoelectric accelerometers (PiXLs). J Microelectromech Syst 10:180

Percin G, Yakub BTK (2002) Piezoelectrically actuated flextensional micromachined ultrasound transducers. Ultrasonics 40:441

Scheeper P, Gullov JO, Kofoe LM (1996) A piezoelectric triaxial accelerometer. J Micromech Microeng 6:131

Ko SC, Kim YC, Lee SS, Choi SH, Kim SR (2003) Micromachined piezoelectric membrane acoustic device. Sens Actuat A 103:130

Lee SS, Ried RP, White RM (1996) Piezoelectric cantilever microphone and microspeaker. J Microelectromech Syst 5:238

Lee SH, Lee SS, Choi JJ, Jeon JU, Ro K (2005) Fabrication of a ZnO piezoelectric microcantilever with a high-aspect-ratio nanotip. Microsyst Technol 11

Brijesh K, Sang-Woo K (2012) Energy harvesting based on semiconducting piezoelectric ZnO nanostructures. Nano Energy 1:342

Prusakova L, Novak P, Kulha P, Ocenasek J, Savkova J, Pastorek L, Sutta P (2015) Modeling and fabrication of single cantilever piezoelectric microgenerator with optimized ZnO active layer. Thin Solid Films

Seidel H, Csepregi L, Heuberger A, Baumgartel H (1990) Anisotropic Etching of Crystalline Silicon in Alkaline Solutions: I . Orientation Dependence and Behavior of Passivation Layers. J Electrochem Soc 137:3626

Marc JM (2002) Fundamentals of Microfabrication, 2nd edn. CRC Press

Taylor RF, Schultz JS (1996) Handbook of chemistry and biological sensors 49. IOP, Bristol

Jo B, Van Lerberghe L, Motsegood K, Beebe D (2000) Three-dimensional micro-channel fabrication in polydimethylsiloxane (PDMS) elastomer. J Microelectromech Syst 9:76

Hosseini Yahya, Zellner Phillip, Agah Masoud (2013) A single-mask process for 3-D microstructure fabrication in PDMS. J Microelectromech Syst 22:356

Du P, Cheng C, Lu H, Zhang X (2013) Investigation of cellular contraction forces in the frequency domain using a PDMS micropillar based force transducer. J Microelectromech Syst 22:44

Xia YN, Whitesides GM (1998) Soft Lithography. Angew Chem Int Ed 37:550

Lee JN, Park C, Whitesides GM (2003) Solvent compatibility of poly(dimethylsiloxane)-based microfluidic devices. Anal Chem 75:6544

Dahiya RS, Valle M (2013) Robotic tactile sensing—technologies and system. Springer, Dordrecht

Rolland JP, Hagberg EC, Denison GM, Carter KR, DeSimoneAngew JM (2004) High-resolution soft lithography: enabling materials for nanotechnologies. Chem Int 43:5796

Liu C (2007) Recent Developments in Polymer MEMS. Adv Mater 19:3783

Peng K-G, Lee S-T (2011) Silicon nanowires for photovoltaic solar energy conversion. Adv Mater 23:198

Ko HC, Baca AJ, Rogers JA (2006) Bulk Quantities of Single-Crystal Silicon Micro-/Nanoribbons Generated from Bulk Wafers. Nano Lett 6:2318

Peng Y, Wang T, Jiang W, Liu X, Wen X, Wang G (2018) Modeling and optimization of inductively coupled wireless bio-pressure sensor system using the design of experiments method. IEEE Trans Compon Pack Manuf Technol 8(1):65

Zhou X-P, Deng R-S, Zhu J-Y (2018) Three-layer-stacked pressure sensor with a liquid metal-embedded elastomer. J Micromech Microeng 28(8):085020

Lee D-W, Choi Y-S (2008) A novel pressure sensor with a PDMS diaphragm. Microelectron Eng 85(5–6):1054

Kim BJ, Meng E (2015) Review of polymer MEMS micromachining. J Micromech Microeng 26(1):013001

Liu X, Zhu Y, Nomani MW, Wen X, Hsia T-Y, Koley G (2013) A highly sensitive pressure sensor using a Au-patterned polydimethylsiloxane membrane for biosensing applications. J Micromech Microeng 23(2):025022

Xue N, Gao G, Sun J, Liu C, Li T, Chi C (2018) Systematic Study and Experiment of Flexible Pressure and Tactile Sensing Array for Wearable Devices Applications. J Micromech Microeng 28(7):075019

Kovacs GTA, Maluf NI, Petersen KE (1998) Bulk micromachining of silicon. Proc IEEE 86–8:1536

Prasad M, Sahula V, Khanna VK (2014) ZnO etching and microtunnel fabrication for high-reliability MEMS Acoustic Sensor. IEEE Trans Device Mater Reliab 14–1:545

Polla DL, Yoon H, Tamagawa T, Voros K (1989) Integration of Surface-Micromachined Zinc Oxide Sensors in n-Well CMOS Technology. IEEE International electron devices meeting. Washington, DC

Prasad M, Sahula V, Khanna VK (2013) Design and fabrication of Si-diaphragm, ZnO piezoelectric film-based MEMS acoustic sensor using SOI wafers. IEEE Trans Semicond Manuf 26–2:233

Kim S-H, Lee J-S, Choi H-C, Lee Y-H (1999) The fabrication of thin-film bulk acoustic wave resonators employing a ZnO/Si composite diaphragm structure using porous silicon layer etching. IEEE Electron Device Lett 20–3:113

Ray R, Ramgopal Rao V (2013) ZnO Nanowire Embedded Strain Sensing Cantilever: A New ultra-sensitive Technology Platform. J Microelectromech Syst 22:995

Jia Y, Sheshia AA (2015) Power optimization by mass tuning for MEMS piezoelectric cantilever vibration energy harvesting. J Microelectromech Syst 25:108

Bausells J (2015) Piezoresistive cantilevers for nanomechanical sensing. Microelectron Eng 145:9

Shokuhfar A, Heydari P, Aliahmadi MR, Mohtashamifar M, Ebrahimi-nejad SR, Zahedinejad M (2012) Low-cost polymeric microcantilever sensor with titanium as piezoresistive material. Microelectron Eng 98:338

Joshi P, Singh J, Sharma R, Jain VK, Akhtar J (2018) A facile approach to fabricate ZnO thin film based micro-cantilevers. Microelectron Eng 187:50

Joshi P, Kumar S, Jain VK, Akhtar J, Singh J (2019) Distributed MEMS Mass-Sensor Based on Piezoelectric Resonant Micro-Cantilevers. J Microelectromech Syst 1057:7157

Tabata O (1996) pH-controlled TMAH etchants for silicon micromachining. Sens Actuat A 53:335

Sakaino K, Adachi S (2001) Study of Si(1 0 0) surfaces etched in TMAH solution. Sens Actuat A 88:71

Joshi P, Singh J, Jain VK, Akhtar J (2020) Nanotechnology for energy and environmental engineering. green energy and technology. Springer, Cham, 495

Takayama S et al (2001) Topographical Micropatterning of Poly(dimethylsiloxane) Using Laminar Flows of Liquids in Capillaries. Adv Mater 13:570

Balakrishnam B, Patil S, Smela E (2009) Patterning PDMS using a combination of wet and dry etching. J Micromech Microeng 19:1

Xu JQ, Pan QY, Shun YA, Tian ZZ (2007) Grain size control and gas sensing properties of ZnO gas sensor. Sens Actuat B 66:277

Williamson GB, Smallman RC (1956) islocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos Mag 1:34

Wang XS, Wu ZC, Webb JF, Liu ZG (2003) Ferroelectric and dielectric properties of Li-doped ZnO thin films prepared by pulsed laser deposition. Appl Phys A 77:561

Barret CS, Massalski TB (1980) Structure of metals. Pergamon Press, Oxford

Stoney GG (1909) The tension of metallic films deposited by electrolysis. Proc R Soc London Ser A 82:172

Acknowledgements

The authors wish to acknowledge the DST-FIST support X-ray diffraction facility of the physics department, BITS Pilani. Dr Jitendra Singh is thanked for his help in the experimental work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Joshi, P., Akhtar, J. (2021). PDMS on ZnO Thin Film: A Mask for ZnO Thin Film in MEMS Fabrication. In: Khan, Z.H. (eds) Emerging Trends in Nanotechnology. Springer, Singapore. https://doi.org/10.1007/978-981-15-9904-0_9

Download citation

DOI: https://doi.org/10.1007/978-981-15-9904-0_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9903-3

Online ISBN: 978-981-15-9904-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)