Abstract

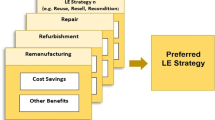

In order to solve the problems of low-process efficiency and high remanufacturing cost caused by uncertainty of service time and damage degree of mechanical and electrical products, a prediction method for active remanufacturing timing of mechanical and electrical products oriented to full life cycle comprehensive cost is proposed. Firstly, based on the analysis of service characteristics of mechanical and electrical products, the concept of comprehensive cost of mechanical and electrical products including three dimensions of energy cost, environmental impact cost and economic cost is proposed. Secondly, based on the life cycle approach, the prediction model of active remanufacturing time is established by analyzing the impact of products on comprehensive cost in different stages of the life cycle. Thirdly, the multi-objective problem is transformed into a single-objective problem by linear weighting method to find the optimal solution which is the best time for active remanufacturing of products. Finally, the research and analysis of a certain type of engine have verified the effectiveness and feasibility of the above method.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bensmain, Y., Dahane, M., Bennekrouf, M., et al.: Preventive remanufacturing planning of production equipment under operational and imperfect maintenance constraints: a hybrid genetic algorithm based approach. Reliab. Eng. Syst. Saf. 185, 546–566 (2019)

Song, S., Wang, W., Ke, Q.: Optimization design of predecisional remanufacturing based on structure coupling matrix. Comput. Integr. Manuf. Syst. 23(4), 744–752 (2017)

Ke, Q., Wang, H., Liu, G., Song, S.: Timing decision-making analysis method for proactive remanufacturing based on performance parameters. China Mech. Eng. 27(14), 1899–1904 (2016)

Qin, X., Hua, Z., Zhigang, J., et al.: A decision-making method for active remanufacturing time based on environmental and economic indicators. Int. J. Online Biomed. Eng. 12(12), 32–37 (2016)

Le, Chen, et al.: Timing decision-making method of engine blades for predecisional remanufacturing based on reliability analysis. Front. Mech. Eng. 14(4), 412–421 (2019)

Liu, Z., Afrinaldi, F., Zhang, H.C., et al.: Exploring optimal timing for remanufacturing based on replacement theory. CIRP Ann. Manuf. Tech. 65(1), 447–450 (2016)

Ke, Q., Wang, H., Song, S., et al.: A timing decision-making method for product and its key components in proactive remanufacturing. Procedia Cirp 48, 182–187 (2016)

Gao, W., Li, T., Peng, S.T., et al.: Optimal timing and recycling operation mode for electro-mechanical products active remanufacturing. Front. Eng. Manag. 3(02), 21–28+90–91 (2016)

Zhao, G., Zhang, H., Zhang, G., Guo, L.: Morphology and coupling of environmental boundaries in an iron and steel industrial system for modelling metabolic behaviours of mass and energy. J. Clean. Prod. 100(8), 247–261 (2015)

Chen, Q., Zhe, Z., Lan, W., et al.: Identifying miRNA-disease association based on integrating miRNA topological similarity and functional similarity. Quant. Biol. 7(3), 202–209 (2019)

Zhao, G., Zhang, X., Fang, C., Ruan, D., Wang, Y.: Systemic boundaries in industrial systems: a new concept defined to improve LCA for metallurgical and manufacturing systems. J. Clean. Prod. 187, 717–729 (2018)

Zhao, G., Gao, X., Yang, S., Duan, J., Hu, J., Guo, X., Wang, Z.: A mechanism model for accurately estimating carbon emissions on a micro scale of the steel industrial system. ISIJ Int. 59(2), 381–390 (2019)

Acknowledgements

This work is financially supported by National Natural Science Foundation of China (Grant No. 51675388).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Yao, X., Zhang, H., Yan, W., Jiang, Z. (2021). A Life Cycle Comprehensive Cost-Based Method for Active Remanufacturing Time Prediction. In: Scholz, S.G., Howlett, R.J., Setchi, R. (eds) Sustainable Design and Manufacturing 2020. Smart Innovation, Systems and Technologies, vol 200. Springer, Singapore. https://doi.org/10.1007/978-981-15-8131-1_41

Download citation

DOI: https://doi.org/10.1007/978-981-15-8131-1_41

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-8130-4

Online ISBN: 978-981-15-8131-1

eBook Packages: EngineeringEngineering (R0)