Abstract

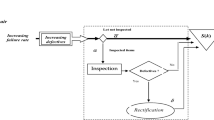

When a manufacturing process is controlled with a Fraction-Defective Control-Chart, the values of 3 decision variables have to be determined: the timing of the samples, the size of the samples, and the distance of the control limits from the central line on the control-chart in terms of standard deviations.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Baker, K.R. (1971): Two process models in the economic design of an X chart, AIIE Transactions Vol. 3, No. 4.

Barlow, R.E., Hunier, L.C. and Proschan, F. (1963): Optimum checking procedures, J. Society of Industrial & Applied Mathematics Vol. 11, 1078–1095.

Barlow, R.E. and Proschan, F. (1965): Mathematical theory of reliability. Pp. 107–118. Wiley: New York.

Chiu, W.K. (1975): Economic design of attribute control charts, Technometrics Vol. 17, 81–87.

Chiu, W.K. and Wetherill, B (1974): A simplified scheme for the economic design of X-Charts, Journal of Ouality Technology April, 63–69.

Duncan, A.J. (1956): The economic design of i-charts used to maintain current control of process, Journal of American Statistical Association Vol. 51, 228–242.

Gibra, T.H. (1971): Economically optimal determination of the parameters of an X chart, AIIE Transactions Vol. 3, No. 4.

Goel, A.L., JAIN, S.D., and WU, S.M. (1968): An algorithm for the determination of the economic design of X-charts based on Duncan’s Model, Journal of the American Statistical Association Vol. 63.

Hall, R.I., and EILON, S. (1963): Controlling production processes which are subject to linear trends, Operational Research Quarterly Vol. 14, No. 3, 279-

Keller, J.B. (1974): Optimum checking schedules for systems subject to random failure, Management Science Vol. 21, No. 3, 256–266.

Knappenberger, H.A. and Grandage, A.H. (1969)• Minimum cost quality control tests, AIIE Transactions Vol. 1, No. 1.

Ladany, S.P. (1973): Optimal use of control charts for controlling current production, Management Sciences Vol. 19, No. 7, 763–772.

Ladany, S.P. and Bedi, Dina N. (1976): Selection of the optimal setup policy, Naval Research Logistics Ouarterly Vol. 23, No. 2, 219–233.

Luss, H. (1983): An inspection policy model for production facilities, Management Science Vol. 29, No. 9, 1102–1109.

Luss, H. and Kander, Z. (1974): Inspection policies when duration of checkings is non-negligible, Operational Research Ouarterly Vol. 25, No. 2, 299–309.

Montgomery, D.C. (1980): The economic design of control charts: A review and literature survey, Journal of Ouality Technology Vol. 12, 75–87.

Montgomery, D.C. and Klatt, PJ. (1972): Economic design of T2 control charts to maintain current control of a process, Management Science Vol. 19, No. 1.

Mumford, A.G. (1981): Comparison among certain inspection policies, Management Science Vol. 27, No. 3, 260–267.

Raz, Z. and Ladany, S.P. (1991) Optimal inspection policy for imperfect inspection in discrete times, Production Planning and Control (forthcoming).

Sackrowitz, H. and Samuel-Cahn. E. (1974): Inspection procedures for Markov chains, Management Science Vol. 21, No. 3, 261–270.

Saniga, E. and Montgomery, D.C. (1981): Economical quality control policies for a single cause system, AILE Transactions Vol. 13, No. 3, 258–264.

Sengupta, B. (1979): Inspection procedures when failure symptoms are delayed, Operations Research Vol. 27, No. 4, 768–776.

Wattanapanom, N. and Shaw, L. (1979): Optimal inspection schedules for failure detection in a model where tests hasten failures, Operations Research Vol. 27, No. 2, 303–317.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1992 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Ladany, S.P., Raz, T. (1992). Optimal Dynamic Application of a Fraction-Defective Control Chart to Control a Production Process. In: Lenz, HJ., Wetherill, G.B., Wilrich, PT. (eds) Frontiers in Statistical Quality Control 4. Frontiers in Statistical Quality Control 4, vol 4. Physica, Heidelberg. https://doi.org/10.1007/978-3-662-11789-7_12

Download citation

DOI: https://doi.org/10.1007/978-3-662-11789-7_12

Publisher Name: Physica, Heidelberg

Print ISBN: 978-3-7908-0642-7

Online ISBN: 978-3-662-11789-7

eBook Packages: Springer Book Archive