Abstract

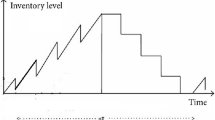

This study proposes a procedure for an on-line process control system to monitor the average number of defects using a Shewhart-like chart with two sets of limits (viz., control and warning limits). After the production of m units, the mth item is inspected. If the number of defects exceeds the upper control limit or if, in a sequence of the last h inspections, all inspected items exhibit a number of defects between the warning and control limits, then the process is stopped for adjustment; otherwise, production continues. The properties of an ergodic Markov chain are used to obtain an expression for the average cost per item produced. The inspection interval (m), warning and control limits (W and C, respectively), and the sequence size (h) are determined by minimizing the average cost per produced item. A numerical example illustrates the proposed procedure.

Similar content being viewed by others

References

Bessegato LF, Quinino RC, Ho LL, Duczmal L (2010) Variable interval sampling in economical designs for online process control of attributes with misclassification errors. J Oper Res Soc 62(7):1365–1375

Chiu WK, Cheung KC (1977) An economic study of X-charts with warning limits. J Qual Technol 9(4):166–171

Chou CY, Chen CH, Liu HR (2004) Effect of nonnormality on the economic design of warning limit X̄ charts. Qual Eng 16(4):567–575

Chung KJ (1993) An economic study of X-charts with warning limits. Comput Ind Eng 24(1):1–7

Glushkovsky EA (1994) “On-line” G-control chart for attribute data. Qual Reliab Eng Int 10(3):217–227

Gordon GR, Weindling JI (1975) Cost model for economic design of warning limit control chart schemes. AIIE Trans 7(3):319–329

Ho LL, Quinino RC (2012) An analysis of Taguchi's on-line quality monitoring procedure for variables based on the results of a sequence of inspections. Pesq Operacional 32:197–212

Lam YC, Shamsuzzaman M, Zhang S, Wu Z (2005) Integrated control chart system-optimization of sample sizes, sampling intervals and control limits. Int J Prod Res 43(3):563–583

Liu HR, Chou CY, Chen CH (2003) The effect of correlation on the economic design of warning limit X-bar charts. Int J Adv Manuf Technol 22(3–4):306–312

Nayebpour MR, Woodall WH (1993) An analyses of Taguchi's on-line quality-monitoring procedures for attributes. Technometrics 35(1):53–60

Page ES (1955) Control charts with warning lines. Biometrics 42(2):243–257

Page ES (1962) A modified control chart with warning limits. Biometrika 49:171–176

Ross SM (1997) Introduction to probability models, 6th edn. Academic, San Diego

Taguchi G (1981) On-line quality control during production. Japanese Standards Association, Tokyo

Taguchi G (1985) Quality engineering in Japan. Bull Jpn Soc Precis Eng 19(4):237–242

Taguchi G, Elsayed EA, Hsiang T (1989) Quality engineering in production systems. McGraw-Hill, New York

Vasconcelos RMR, Medeiros PG, Ho LL (2012) On-line process control of the number of non-conformities in the inspected item. Braz J Oper Prod Manag 9:55–69

Western Electric Company (1956) Statistical quality control handbook. Indianapolis, Indiana

Wu Z, Jiao J (2008) A control chart for monitoring process mean based on attribute inspection. Int J Prod Res 46(15):4331–4347

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sena da Rocha, A.L., Guedes de Medeiros, P. & Lee Ho, L. Economical control chart with supplementary rules to monitor the average number of defects. Int J Adv Manuf Technol 76, 881–891 (2015). https://doi.org/10.1007/s00170-014-6237-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6237-1