Abstract

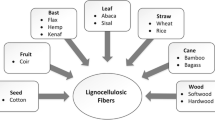

For some time now, nanocellulose has been at the focus of a good deal of industrial and scientific interest as a novel biomaterial due to their wide abundance, their renewability, and their outstanding mechanical properties. Cellulose is the most abundant biopolymer on earth, derived from a variety of living species. Cotton linter is the by-product from cotton textile and has high cellulose content, beside pectins, proteinaceous matter, waxes, ash, and minor soluble polysaccharides. As an essentially regenerative natural resource, it has been applied widely owing to its low cost. This chapter provides an overview of the recent research on the fundamental and composite properties of nanoparticles extracted from cotton linter. It contains a general introduction to cellulose and basic techniques of nanocellulose preparation with its properties. The incorporation of nanocellulose in composite materials including processing methods and properties is also presented.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: A review. Carbohydr Polym 87:963

Angellier H, Putaux JL, Molina-Boisseau S, Dupeyre D, Dufresne A (2005) Starch nanocrystals fillers in an acrylic polymer matrix. Macromol Symp 221:95

Araki J, Kuga S (2001) Effect of Trace Electrolyte on Liquid Crystal Type of Cellulose Microcrystals. Langmuir 17:4493

Araki J, Wada M, Kuga S, Okano T (1998) Flow properties of microcrystalline cellulose suspension prepared by acid treatment of native cellulose. Colloid Surface A 142:75

Araki J, Wada M, Kuga S, Okano T (1999) Influence of surface charge on viscosity behavior of cellulose microcrystal suspension. J Wood Sci 45:258

Ass BAP, Ciacco GT, Frollini E (2006) Cellulose acetates from linters and sisal: Correlation between synthesis conditions in DMAc/LiCl and product properties. Bioresour Technol 97:1696

Azizi Samir MAS, Alloin F, Dufresne A (2005) Review of Recent Research into Cellulosic Whiskers, Their Properties and Their Application in Nanocomposite Field. Biomacromolecules 6:612

Azizi Samir MAS, Alloin F, Paillet M, Dufresne A (2004) Preparation of Cellulose Whiskers Reinforced Nanocomposites from an Organic Medium Suspension. Macromolecules 37:4313

Beck-Candanedo S, Roman M, Gray DG (2005) Effect of reaction conditions on the properties and behavior of wood cellulose nanocrystal suspensions. Biomacromolecules 6:1048

Cao X, Dong H, Li CM (2007) New nanocomposite materials reinforced with flax cellulose nanocrystals in waterborne polyurethane. Biomacromolecules 8:899

Capadona JR, Shanmuganathan K, Trittschuh S, Seidel S, Rowan SJ, Weder C (2009) Polymer nanocomposites with nanowhiskers isolated from microcrystallinecellulose. Biomacromolecules 10:712

Chang CP, Perng YS, Wang EI (2012) Institute of Paper Science and Technology at Georgia Tech, Biomaterials Posters. www.ipst.gatech.edu/faculty/ragauskas_art/global/…/biomaterials_5.pdf

Chen W, Yu H, Liu Y, Chen P, Zhang M, Yunfei H (2011) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohydr Polym 83:804

Cherian BM, Leão AL, de Souza SF, Costa LMM, de Olyveira GM, Kottaisamy M, Nagarajan ER, Thomas S (2011) Cellulose nanocomposites with nanofibres isolated from pineapple leaf fibers for medical applications. Carbohydr Polym 86:1790

De Souza Lima M, Borsali R (2004) Rodlike Cellulose Microcrystals: Structure, Properties, and Applications. Macromol Rapid Commun 25:771

De Souza Lima MM, Wong JT, Paillet M, Borsali R, Pecora R (2003) Translational and Rotational Dynamics of Rodlike Cellulose Whiskers. Langmuir 19:24

Dong XM, Revol JF, Gray DG (1998) Effect of microcrystallite preparation conditions on the formation of colloid crystals of cellulose. Cellulose 5:19

Dufresne A (2006) Comparing the Mechanical Properties of High Performances Polymer Nanocomposites from Biological Sources. J Nanosci Nanotechnol 6:322

Dufresne A (2010) Processing of Polymer Nanocomposites Reinforced with Polysaccharide Nanocrystals. Molecules 15:4111

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito AN, Mangalam A, Simonsen J, Benight AS, Bismarck A, Berglund LA, Peijs T (2010) Review: Current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1

FAOSTAT (FOOD AND AGRICULTURE ORGANIZATION OF THE UNITED NATIONS) Agricultural data (2012) Production. Crops. Food and Agriculture Organization of the United Nations. http://faostat.fao.org/default.aspx/. Accessed 02 May 2012

Favier V, Canova GR, Cavaillé JY, Chanzy H, Dufresne A, Gauthier C (1995) Nanocomposite materials from latex and cellulose whiskers. Polym Adv Technol 6:351

de Garcia de Rodriguez NL, Thielemans W, Dufresne A (2006) Sisal cellulose whiskers reinforced polyvinyl acetate nanocomposites. Cellulose 13:261

Helbert W, Cavaillé JY, Dufresne A (1996) Thermoplastic nanocomposites filled with wheat straw cellulose whiskers. Part I: Processing and mechanical behavior. Polym Compos 17:604

Ibrahim MM, El-Zawawy WK, Nassar MA (2010) Synthesis and characterization of polyvinyl alcohol/nanospherical cellulose particle films. Carbohydr Polym 79:694

Itoh T, Brown RM Jr (1984) The assembly of cellulose microfibrils in Valonia macrophysa. Planta 160:372

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Cellulose: Fascinating biopolymer and sustainable raw material. Angew Chem Int Edit 44:3358

Lin N, Chen G, Huang J, Dufresne A, Chang PR (2009) Effects of polymergrafted natural nanocrystals on the structure and mechanical properties of poly(lactic acid): A case of cellulose whisker-graft-polycaprolactone. J Appl Polym Sci 113:3417

Mathew AP, Dufresne A (2002) Morphological Investigation of Nanocomposites from Sorbitol Plasticized Starch and Tunicin Whiskers. Biomacromolecules 3:609

Mohanty AK, Misra M, Hinrichsen G (2000) Biofibres, biodegradable polymers and biocomposites: An overview. Macromol Mater Eng 276/277:1

Morais JPS, Rosa MF, de Souza Filho MM, do Nascimento LD, Nascimento DM, Cassales A (2013) Extraction and characterization of nanocellulose structures from raw cotton linter. Carbohydr Polym 91:229

Oksman K, Mathew AP, Bondeson D, Kvien I (2006) Manufacturing process of cellulose whiskers/polylactic acid nanocomposites. Compos Sci Technol 66:2776

Pääkkö M, Vapaavuori J, Silvennoinen R, Kosonen H, Ankerfors M, Lindström T, Berglund LA, Ikkala O (2008) Long and entangled native cellulose I nanofibers allow flexible aerogels and hierarchically porous templates for functionalities. Soft Matter 4:2492

Pandey JK, Ahn SH, Lee CS, Mohanty AK, Misra M (2010) Recent advances in the application of natural fiber based composites. Macromol Mater Eng 295:975

Pandey JK, Kumar AP, Misra M, Mohanty AK, Drzal LT, Singh RP (2005) Recent advances in biodegradable nanocomposites. J Nanosci Nanotechnol 5:497

Petersson L, Kvien I, Oksman K (2007) Structure and thermal properties of poly(lactic acid)/cellulose whiskers nanocomposite materials. Compos Sci Technol 67:2535

Plackett D, Andersen TL, Pedersen WB, Nielsen L (2003) Biodegradable composites based on l -polylactide and jute fibres. Compos Sci Technol 63:1287

Rånby BG, Ribi E (1950) The microstructure of cellulose. Experientia 6:12

Rånby BG (1949) Aqueous Colloidal Solutions of Cellulose Micelles. Acta Chem Scand 3:649

Rhim JW (2007) Potential use of biopolymer-based nanocomposite films in food packaging applications. Food Sci Biotechnol 16:691

Roman M, Winter WT (2004) Effect of Sulfate Groups from Sulfuric Acid Hydrolysis on the Thermal Degradation Behavior of Bacterial Cellulose. Biomacromolecules 5:1671

Roohani M, Habibi Y, Belgacem NM, Ebrahim G, Karimi AN, Dufresne A (2008) Cellulose whiskers reinforced polyvinyl alcohol copolymers nanocomposites. Eur Polym J 44:2489

Rosa MF, Medeiros ES, Malmonge JA, Gregorski KS, Wood DF, Mattoso LHC, Glenn G, Orts WJ, Imam SH (2010) Cellulose nanowhiskers from coconut husk fibers: Effect of preparation conditions on their thermal and morphological behavior. Carbohydr Polym 81:83

Sczostak A (2009) Cotton linters: An alternative cellulosic raw material. Macromol Symp 280:45

Shanmuganathan K, Capadona JR, Rowan SJ, Weder C (2010) Bio-inspired mechanically-adaptive nanocomposites derived from cotton cellulose whiskers. J Mater Chem 20:180

Silva R, Haraguchi SK, Muniz EC, Rubira AF (2009) Aplicac, ões de fibras lignocelulósicas na química de polímeros e em compósitos. Quim Nova 32:661

Siqueira G, Bras J, Dufresne A (2009) Cellulose whiskers versus microfibrils: Influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites. Biomacromolecules 10:425

Sorrentino A, Vittoria GGV (2007) Potential perspectives of bio-nanocomposites for food packaging applications. Trends Food Sci Tech 18:84

Stelte W, Sanadi AR (2009) Preparation and characterization of cellulose nanofibers from two commercial hardwood and softwood pulps. Ind Eng Chem Res 48:11211

Sun Y, Yue Q, Gao B, Li Q, Huang L, Yao F, Xu X (2012) Preparation of activated carbon derived from cotton linter fibers by fused NaOH activation and its application for oxytetracycline (OTC) adsorption. J Colloid Interface Sci 368:521

Teixeira EM, Corrêa AC, Manzoli A, Leite FL, Oliveira CR, Mattoso LHC (2010) Cellulose nanofibers from white and naturally colored cotton fibers. Cellulose 17:595

Ummartyotin S, Juntaro J, Sain M, Manuspiya H (2012) Development of transparent bacterial cellulose nanocomposite film as substrate for flexible organic light emitting diode (OLED) display. Ind Crop Prod 35:92

Wang SQ, Cheng QZ (2009) A novel process to isolate fibrils from cellulose fibers by high-intensity ultrasonication. Part 1: Process optimization. J Appl Polym Sci 113:1270

Yang Q, Fukuzumi H, Saito T, Isogai A, Zhang L (2011) Transparent cellulose films with high gas barrier properties fabricated from aqueous alkali/urea solutions. Biomacromolecules 12:2766

Yu H, Liu RG, Shen DW, Jiang Y, Huang Y (2005) Study on morphology and orientation of cellulose in the vascular bundle of wheat straw. Polymer 46:5689

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Ibrahim, M.M., El-Zawawy, W.K. (2015). Extraction of Cellulose Nanofibers from Cotton Linter and Their Composites. In: Pandey, J., Takagi, H., Nakagaito, A., Kim, HJ. (eds) Handbook of Polymer Nanocomposites. Processing, Performance and Application. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-45232-1_76

Download citation

DOI: https://doi.org/10.1007/978-3-642-45232-1_76

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-45231-4

Online ISBN: 978-3-642-45232-1

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)