Abstract

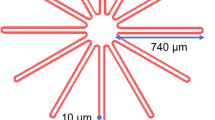

This abstract outlines current developments of a micro-assembly facility focusing on studies using a three fingered gripper. Individual fingers of the gripper comprise thin fibers ranging in diameter from 7 to 80 μm that are attached to quartz based oscillators and are capable of sensing proximity, contact, and controlling adhesion forces. To optimize gripper finger performance, an electrolytic etching facility has been used to selectively modify oscillator performance and this system is currently being developed for automated processing. To demonstrate current performance of the gripper system, a micro-CMM contact sensing probe has been assembled and a preliminary performance evaluation is presented.

Chapter PDF

Similar content being viewed by others

Keywords

References

Hastings, D.J., Graham, J., Nowakowski, B., Smith, S.T., Tomblin, J.: A three fingered hand for a micro-assembly system. In: Proc. ASPE, vol. 50, pp. 93–96 (2010)

Bauza, M., Woody, S.C., Hocken, R.J., Smith, S.T.: Development of a virtual probe tip with an application to high aspect ratio microscale features. Rev. Sci. Instrum. 76(9), 95112 (8 pages) (2005)

Woody, S.C., Nowakowski, B., Bauza, M., Smith, S.T.: Standing wave probes for micro-assembly. Rev. Sci. Instrum. 79, 85107 (9 pages) (2008)

Bauza, M.B., Woody, S.C., Woody, B.A., Smith, S.T.: Surface profilometry of high aspect ratio features. Wear 271, 519–522 (2011)

Bauza, M., Woody, S.C., Smith, S.T., Woody, B.A.: Microscale surface and form profilometry using a standing wave probe. In: Metromet Conference, Bilboa, Spain (February 2010)

Bauza, M., Woody, S.C., Seugling, R.M., Smith, S.T.: Dimensional measurements of ultra delicate materials using micrometrology tactile sensing. In: Proc. ASPE, vol. 50, pp. 73–76 (2010)

Lin, F., Smith, S.T., Ghazanfar, H.: Knife edge position transducer performance studies. Precision Engineering (submitted, 2011)

Insitutec Inc., 45 Odell School Road Suite A, Concord, North Carolina 28027, insitutec.com.

Nowakowski, B., Smith, S.T., Pratt, J., Shaw, G.: Electrolysis for precision mass removal. Rev. Sci. Instrum. (to be submitted, 2011)

Author information

Authors and Affiliations

Editor information

Rights and permissions

Copyright information

© 2012 IFIP International Federation for Information Processing

About this paper

Cite this paper

Chesna, J.W., Smith, S.T., Hastings, D.J., de la Maza, B., Nowakowski, B.K., Lin, F. (2012). Development of a Micro-scale Assembly Facility with a Three Fingered, Self-aware Assembly Tool and Electro-chemical Etching Capabilities. In: Ratchev, S. (eds) Precision Assembly Technologies and Systems. IPAS 2012. IFIP Advances in Information and Communication Technology, vol 371. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-28163-1_1

Download citation

DOI: https://doi.org/10.1007/978-3-642-28163-1_1

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-28162-4

Online ISBN: 978-3-642-28163-1

eBook Packages: Computer ScienceComputer Science (R0)