Abstract

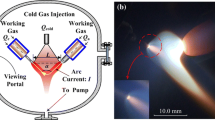

Numerical modeling of the thermal plasma process was carried out based on the thermal plasma reactor in our lab and confirmed using experimental data. The inlet boundary conditions of a non-transferred DC arc thermal plasma reactor were used in modeling the temperature and fluid flow distribution in the reactor. Different mesh grid sizes were used to confirm the model is independent of grid size. Temperature profile and gas flow distribution in the thermal plasma reactor were developed by the computational fluid dynamics (CFD) with ANSYS Fluent. The predicted temperatures are in good agreement with the experimentally measured temperatures in the reactor. The influence of plasma torch input power as well as the plasma gas flux on the temperature distribution was investigated using this model. The influence of power input and gas flow rate on temperature and velocity distributions are not independent. Generally, higher power input and lower gas flow rate will give rise to the temperature increase in the reactor.

Similar content being viewed by others

References

M.I. Boulos, Thermal plasma processing. IEEE Trans. Plasma Sci. 19(6), 1078–1089 (1991)

H.-C. Lee, S. Dhage, M.S. Akhtar, D.H. Kwak, W.J. Lee, C.-Y. Kim, O.-B. Yang, A simulation study on the direct carbothermal reduction of SiO2 for Si metal. Curr. Appl. Phys. 10(2), S218–S221 (2010)

N. Thakkar, R.G. Reddy, Thermal plasma production of B4C nanopowders. J. Manuf. Sci. Prod. 7(2), 87–100 (2006)

L. Tong, R.G. Reddy, Synthesis of titanium carbide nano-powders by thermal plasma. Scr. Mater. 52(12), 1253–1258 (2005)

S. Niyomwas, B. Wu, R.G. Reddy, Synthesis of Fe-TiN Composites by Thermal Plasma Processing. Ultrafine Grained Materials (as held at the 2000 TMS Annual Meeting, 2000), pp. 89–98

L. Tong, R.G. Reddy, Thermal plasma synthesis of SiC nano-powders/nano-fibers. Mater. Res. Bull. 41(12), 2303–2310 (2006)

S.Y. Mashayak, CFD Modeling of Plasma Thermal Reactor for Waste Treatment (Purdue University West Lafayette, 2009)

H. Lorcet, D. Guenadou, C. Latge, M. Brothier, G. Mariaux, A. Vardelle, kinetics modeling of biomass gasification under thermal plasma conditions. Application to a refractory species: the methane. International symposium on plasma chemistry, Germany (Bochum, 2009)

I.B. Matveev, S. Serbin, Modeling of the coal gasification processes in a hybrid plasma torch. IEEE Trans. Plasma Sci. 35(6), 1639–1647 (2007)

F. Qunbo, W. Lu, W. Fuchi, Modeling influence of basic operation parameters on plasma jet. J. Mater. Process. Technol 198(1), 207–212

Y.A. Mankelevich, M. Ashfold, A. Orr-Ewing, Measurement and modeling of Ar∕H2∕CH4 arc jet discharge chemical vapor deposition reactors II: Modeling of the spatial dependence of expanded plasma parameters and species number densities. J. Appl. Phys. 102(6), 063310 (2007)

R. Williamson, J. Fincke, D. Crawford, S. Snyder, W. Swank, D. Haggard, Entrainment in high-velocity, high-temperature plasma jets.: Part II: computational results and comparison to experiment. Int. J. Heat Mass Transf. 46(22), 4215–4228 (2003)

N. Agon, J. Vierendeels, M. Hrabovský, A. Murphy, G. Van Oost, Interaction of a H2O/AR plasma jet with nitrogen atmosphere: effect of the method for calculating thermophysical properties of the gas mixture on the flow field. Plasma Chem. Plasma Process. 35(2), 365–386 (2015)

L. Yan, L. Yudong, Z. Ting’an, F. Naixiang, Research on the penetration depth in aluminum reduction cell with new type of anode and cathode structures. JOM 66(7), 1202–1209 (2014)

Y. Li, R. Reddy, Experimental and numerical investigation of thermal plasma synthesis of silicon. J. Manuf. Sci. Prod. 15(4), 345–354 (2015)

J. Ramshaw, C. Chang, Computational fluid dynamics modeling of multicomponent thermal plasmas. Plasma Chem. Plasma Process. 12(3), 299–325 (1992)

C. Chang, J. Ramshaw, Numerical simulations of argon plasma jets flowing into cold air. Plasma Chem. Plasma Process. 13(2), 189–209 (1993)

J. Fincke, C. Chang, W. Swank, D. Haggard, Entrainment and demixing in subsonic thermal plasma jets: comparison of measurements and predictions. Int. J. Heat Mass Transf. 37(11), 1673–1682 (1994)

A. Fluent, Release 14.0, User Guide, Ansys, Inc., Lebanon, US (2011)

H. Lorcet, M. Brothier, D. Guenadou, C. Latge, A. Vardelle, Modeling bio-oil gasification by a plasma process. High Temp. Mater. Proc.: An Int. Q. High-Technol. Plasma Process. 14(1–2) (2010)

M. Hrabovsky, V. Kopecký, V. Sember, T. Kavka, O. Chumak, M. Konrad, Properties of hybrid water/gas DC arc plasma torch. IEEE Trans. Plasma Sci. 34(4), 1566–1575 (2006)

J. Fincke, D. Crawford, S. Snyder, W. Swank, D. Haggard, R. Williamson, Entrainment in high-velocity, high-temperature plasma jets. Part I: experimental results. Int. J. Heat Mass Transf. 46(22), 4201–4213 (2003)

M. Ramachandran, R.G. Reddy, Thermal plasma synthesis of SiC. Advances in Manufacturing 1(1), 50–61 (2013)

R.G. Reddy, L.V. Antony, Processing of SiC nano powders using thermal plasma technique. In Proceedings of the International Conference on Nanotechnology: Scientific Challenges and Commercial Opportunities, (Rhode Island, pp. 17–18, 2003)

L. Tong, R.G. Reddy, In situ synthesis of TiC-Al (Ti) nanocomposite powders by thermal plasma technology. Metall. Mater. Trans. B 37(4), 531–539 (2006)

Acknowledgments

The authors are thankful for the financial support from National Science Foundation (NSF) agency (Grant No. DMR-1310072), American Cast Iron Pipe Company (ACIPCO) and The University of Alabama during the course of the current research project.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Li, Y., Reddy, R. (2017). Numerical Study of the Fluid Flow and Temperature Distribution in a Non-transferred DC ARC Thermal Plasma Reactor. In: Wang, S., Free, M., Alam, S., Zhang, M., Taylor, P. (eds) Applications of Process Engineering Principles in Materials Processing, Energy and Environmental Technologies. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-51091-0_43

Download citation

DOI: https://doi.org/10.1007/978-3-319-51091-0_43

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-51090-3

Online ISBN: 978-3-319-51091-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)