Abstract

The present chapter deals with a brief account on various topics in rubber based bionanocomposites: preparation and state of art. This chapter discussed with different topics such as cellulose based rubber nanocomposites, chitin based rubber nanocomposites, applications of chitin based rubber nanocomposites, chitin in rubber based blends and micro composites, starch in rubber based blends and micro composites, polylactic acid based rubber composites and nanocomposites, applications of rubber based biocomposites and bionanocomposites, vinyl ester (BisGMA)/SEBS/f-MWCNTs based nanocomposites preparation and applications and starch based rubber nanocomposites.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

R.L. Crawford, Lignin Biodegradation and Transformation (Wiley, New York, 1981). ISBN 0-471-05743-6

R. Young, Cellulose Structure Modification and Hydrolysis (Wiley, New York, 1986). ISBN 0471827614

D.M. Updegraff, Anal. Biochem. 32, 420–424 (1969)

S. Kuga, R.M. Brown, Carbohydr. Res. 180, 345–350 (1988)

K.R.Z. Andress, J. Phys. Chem. Part B 190, 38 (1929)

Y. Habibi, L.A. Lucia, O.J. Rojas, Chem. Rev. 110, 3479–3500 (2010)

H. Chanzy, Y. Nishiyama, P. Langan, J. Am. Chem. Soc. 121(43), 9940–9946 (1999)

C. Klason, J. Kubat, H.E. Stromvall, Int. J. Polym. Mater. 11(1), 9–38 (1985)

P. Zadorecki, A.J. Michell, Polym. Compos. 10(2), 69–77 (1989)

D. Maldas, B.V. Kokta, R. Raj, G.C. Daneault, Polymer 29(7), 1255–1265 (1988)

P. Terech, L. Chazeau, J.-Y. Cavaille, Macromolecules 32, 1872–1875 (1999)

F.G. Torres, R. Flores, J.F. Dienstmaier, O.A. Quintana, Polym. Compos. 13, 753–764 (2005)

F.G. Torres, O.H. Arroyo, C. Gomez, Thermoplast. Compos. Mater. 20, 207–223 (2007)

F.G. Torres, C.L. Aragon, Polym. Test. 25, 568–577 (2006)

F.G. Torres, O.H. Arroyo, C. Grande, E. Esparza, Int. J. Polym. Mater. 55, 1115–1132 (2006)

C. Grande, F.G. Torres, Adv. Polym. Technol. 24, 145–156 (2005)

M. Roman, W.T. Winter, Biomacromolecules 5, 1671–1677 (2004)

M.S. Peresin, Y. Habibi, J.O. Zoppe, J.J. Pawlak, O.J. Rojas, Biomacomolecules 11, 674–681 (2010)

T. Zimmermann, E. Pöhler, T. Geiger, Adv. Eng. Mater. 6, 754–761 (2004)

M.A.S. Azizi Samir, F. Alloin, J.-Y. Sanchez, A. Dufresne, Macromolecules 37, 4839–4844 (2004)

C. Legnani, C. Vilani, V.L. Calil, H.S. Barud, W.G. Quirino, C.A. Achete, S.J.L. Ribeiro, M. Cremona, Thin Solid Films 517, 1016–1020 (2008)

D.R. Rathke, S.M. Hudson, J. Macromol. Sci. Rev. Macromol. Chem. Phys. 34, 375 (1994)

W. Arbia, L. Arbia, L.A.A. Adour, Chitin extraction from crustacean shells using biological methods—a review. Food Technol. Biotechnol. 51, 12–25 (2013)

K. Gopalan Nair, A. Dufresne, Crab shell chitin whisker reinforced natural rubber nanocomposites. 1. Processing and swelling behavior. Biomacromolecules 4(3), 657–665 (2003)

D.K. Singh, A.R.J. Ray, Macromol. Sci. Rev. Macromol. Chem. Phys. C40, 69 (2000)

Y. Lu, L. Weng, L. Zhang, Biomacromolecules 5, 1046 (2004)

M. Paillet, A. Dufresne, Macromolecules 34, 6527 (2001)

S.I Fuku, M. Nogi, K. Abe, M. Yoshioka, M. Morimoto, H. Saimoto, H. Yano, Carbohydr. Polym. 84, 762 (2011)

P. Wongpanit, N. Sanchavanakit, P. Pavasant, T. Bunaprasert, Y. Tabata, R. Rujiravanit, Eur. Polym. J. 43, 4123 (2007)

J.-B. Zeng, Y.-S. He, S.-L. Li, Y.-Z. Wang, Biomacromolecules 13, 1 (2012)

M.J. Zaini, M.Y.A. Fuad, H. Ismail, M.S. Mansor, J. Mustafah, Polym. Int. 40, 51 (1996)

B. Krajewska, Enzym. Micro Technol. 35, 126–139 (2004)

N.L. Yusof, A. Wee, L.Y. Lim, E. Khor, Biomed. Mater. Res. Part A 66A, 224–232 (2003)

M. Kanke, H. Katayama, S. Tsuzuki, H. Kuramoto, Chem. Pharm. Bull. 37, 523–525 (1989)

Y. Kato, H. Onishi, Y.J. Machida, Curr. Pharm. Biotechnol. 4, 303–309 (2003)

K. Gopalan Nair, A. Dufresne, Biomacromolecules 4(3), 657–665 (2003)

A. Morin, A. Dufresne, Macromolecules 35, 2190–2199 (2002)

K. Gopalan Nair, A. Dufresne, Biomacromolecules 4(3), 666–674 (2003)

K. Gopalan Nair, A. Dufresne, Biomacromolecules 4(6), 1835–1842 (2003)

M.A.S. Azizi Samir, F. Alloin, J.Y. Sanche, N. El Kissi, A. Dufresne, Macromolecules 37, 1386–1393 (2004)

R.J. Rujiravanit, J. Sriupayo, P. Supaphol, J. Blackwell, Carbohydr. Polym. 62, 130–136 (2005)

E. Ruiz-Hitzky, M. Darder (eds.), Curr. nanosci. 2, 153–294 (2006)

J.K. Pandey, A.P. Kumar, M. Misra, A.K. Mohanty, L.T. Drzal, R.P.J. Singh, j. nanosci. nanotechnol. 5(4), 497–526 (2005)

C. Gousse, H. Chanzy, G. Excoffier, L. Soubeyrand, E. Fleury, Polymer 43, 2645–2651 (2002)

O.J. Rojas, G.A. Montero, Y. Habibi, J. Appl. Polym. Sci. 113, 927–935 (2009)

Y. Matsushita, A. Suzuki, T. Sekiguchi, K. Saito, T. Imai, K. Fukushima, Appl. Surf. Sci. 255, 1022–1024 (2008)

V.G. Geethamma, G. Kalaprasad, G. Groeninckx, S. Thomas, Dynamic mechanical behavior of short coir fiber reinforced natural rubber composites. Compos. Part A Appl. Sci. Manufact. 36(11), 1499–1506 (2005)

V.G. Geethamma, S. Thomas, Diffusion of water and artificial seawater through coir fiber reinforced natural rubber composites. Polym. Compos. 26(2), 136–143 (2005)

K.M. Zia, M. Barikani, M. Zuber, I.A. Bhatti, M.A. Sheikh, Molecular engineering of chitin based polyurethane elastomers. Carbohydr. Polym. 74(2), 149–158 (2008)

M. Barikani, H. Honarkar, M. Barikani, Synthesis and characterization of polyurethane elastomers based on chitosan and poly(epsilon-caprolactone). J. Appl. Polym. Sci. 112(5), 3157–3165 (2009)

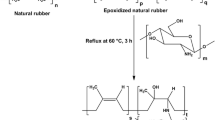

H. Ismail, S.M. Shaari, N. Othman, The effect of chitosan loading on the curing characteristics, mechanical and morphological properties of chitosan-filled natural rubber (NR), epoxidised natural rubber (ENR) and styrene-butadiene rubber (SBR) compounds. Polym. Test. 30(7), 784–790 (2011)

H. Ismail, F.S. Haw, Effects of palm ash loading and maleated natural rubber as a coupling agent on the properties of palm-ash-filled natural rubber composites. J. Appl. Polym. Sci. 110(5), 2867–2876 (2008)

K.M. Zia, K. Mahmood, M. Zuber, T. Jamil, M. Shafiq, Chitin based polyurethanes using hydroxyl terminated polybutadiene. Part I: molecular engineering. Int. J. Biomacromolecules 59, 320–327 (2013)

K.M. Zia, M. Zuber, M.J. Saif, M. Jawaid, K. Mahmood, M. Shahid et al., Chitin based polyurethanes using hydroxyl terminated polybutadiene, part III: surface characteristics. Int. J. Biomacromolecules 62, 670–676 (2013)

K. Gopalan Nair, A. Dufresne, A. Gandini, M.N. Belgacem, Crab shell chitin whiskers reinforced natural rubber nanocomposites. 3. Effect of chemical modification of chitin whiskers. Biomacromolecules 4(6), 1835–1842 (2003)

R.A.A. Muzzarelli, P. Morganti, G. Morganti, P. Palombo, M. Palombo, G. Biagini et al., Chitin nanofibrils/chitosan glycolate composites as wound medicaments. Carbohydr. Polym. 70(3), 274–284 (2007)

A. Morin, A. Dufresne, Nanocomposites of chitin whiskers from Riftia tubes and poly(caprolactone). Macromolecules 35(6), 2190–2199 (2002)

S. Phongying, S. Aiba, S. Chirachanchai, Direct chitosan nanoscaffold formation via chitin whiskers. Polymer 48(1), 393–400 (2007)

M. Mincea, A. Negrulescu, V. Ostafe, Preparation, modification, and applications of chitin nanowhiskers: a review. Rev. Adv. Mater. Sci. 30(3), 225–242 (2012)

K. Gopalan Nair, A. Dufresne, Crab shell chitin whisker reinforced natural rubber nanocomposites. 2. Mechanical behavior. Biomacromolecules 4(3), 666–674 (2003)

M.A. Garcia, M.N. Martino, N.E. Zaritzky, Starch-based coatings: effect on refrigerated strawberry (Fragaria ananassa) quality. J. Sci. Food Agric. 76, 411–420 (1998)

S.H. Imam, S.H. Gordon, L. Mao, L. Chen, Environmentally friendly wood adhesive from a renewable plant polymer: characteristics and optimization. Polym. Degrad. Stab. 73, 529–533 (2001)

Y. Wei, F. Cheng, H. Zheng, Synthesis and flocculating properties of cationic starch derivatives, Carbohydr. Polym. 74, 673–679 (2008)

J. Wu, Y. Wei, J. Lin, S. Lin, Study on starch-graft-acrylamide/mineral powder super absorbent composite. Polymer 44, 6513–6520 (2003)

B.R. Pant, H.-J. Jeon, H.H. Song, Radiation cross-linked carboxymethylated starch and iron removal capacity in aqueous solution. Macromol. Res. 19, 307–312 (2011)

M.-C. Li, J.K. Lee, U.R. Cho, Synthesis, characterization, and enzymatic degradation of starch-grafted poly(methyl methacrylate) copolymer films. J. Appl. Polym. Sci. 125, 405–414 (2012)

E.D.M. Teixeira, D. Pasquini, A.A.S. Curvelo, E. Corradini, M.N. Belgacem, A. Dufresne, Cassava bagasse cellulose nanofibrils reinforced thermoplastic cassava starch. Carbohydr. Polym. 78, 422–431 (2009)

D. Liu, Q. Wu, H. Chen, P.R. Chang, Transitional properties of starch colloid with particle size reduction from micro- to nanometer. J. Colloid Interface Sci. 339, 117–124 (2009)

A. Shi, D. Li, L. Wang, B. Lia, B. Adhikari, Preparation of starch-based nanoparticles through high-pressure homogenization and miniemulsion cross-linking: influence of various process parameters on particle size and stability. Carbohydr. Polym. 83, 1604–1610 (2011)

X. Ma, R. Jian, P.R. Chang, R. Yu, Fabrication and characterization of citric acid-modified starch nanoparticles/plasticized-starch composites. Biomacromolecules 9, 3314–3320 (2008)

Y. Tan, K. Xu, L. Li, C. Liu, C. Song, P. Wang, Fabrication of size-controlled starch-based nanospheres by nanoprecipitation. ACS Appl. Mater. Interfaces 1, 956–959 (2009)

S. Xiao, X. Liu, C. Tong, J. Liu, D. Tang, L. Zhao, Studies of poly-L-lysine-starch nanoparticle preparation and its application as gene carrier. Sci. China Ser. B Chem. 48, 162–9166 (2005)

D. Yu, S. Xiao, C. Tong, C. Lin, X. Liu, Dialdehyde starch nanoparticles: preparation and application in drug carrier. Chinese Sci. Bull. 52, 2913–2918 (2007)

S.F. Chin, S.C. Pang, S.H. Tay, Size controlled synthesis of starch nanoparticles by a simple nanoprecipitation method. Carbohydr. Polym. 86, 1817–1819 (2011)

Y.-J. Wang, V.-D. Truong, L. Wang, Structures and physicochemical properties of acid-thinned corn, potato and rice starches. Starch/Starke 53, 570–576 (2001)

V.D. Athawale, V. Lele, Syntheses and characterisation of graft copolymers of maize starch and methacrylonitrile. Carbohydr. Polym. 41, 407–416 (2000)

A.J.F. Carvalho, A.E. Job, N. Alves, A.A.S. Curvelo, A. Gandini, Thermoplastic starch/natural rubber blends. Carbohydr. Polym. 53, 95–99 (2003)

A.I. Khalaf, E.M. Sadek, Compatibility study in natural rubber and maize starch blends. J. Appl. Polym. Sci. 125, 959–967 (2012)

Z.F. Wang, Z. Peng, S.D. Li, H. Lin, K.X. Zhang, X.D. She, X. Fu, The impact of esterification on the properties of starch/natural rubber composites. Compos. Sci. Technol. 69, 1797–1803 (2009)

M.C. Li, X. Ge, U.R. Cho, Emulsion grafting vinyl monomers onto starch for reinforcement of styrene-butadiene rubber. Macromol. Res. 21, 519–528 (2013)

D. LeCorre, J. Bras, A. Dufresne, Influence of the botanic origin of starch nanocrystals on the morphological and mechanical properties of natural rubber nanocomposites, Macromol. Mater. Eng. Doi:10.1002/mame.201100317

M.M. Senna, R.M. Mohamed, A.N. Shehab-Eldin, S. El-Hamouly, Characterization of electron beam irradiated natural rubber/modified starch composites. J. Ind. Eng. Chem. 18, 1654–1661 (2013)

Y.P. Wu, G.H. Liang, L.Q. Zhang, Influence of starch on the properties of carbonblackfilled styrene–butadiene rubber composites. J. Appl. Polym. Sci. 114(4), 2254–2260 (2009)

D.J. Sawyer, Bioprocessing; no longer a field of dreams. Macromol. Symp. 201, 271–281 (2003)

J.R. Dorgan, H.J. Lehermeier, L.I. Palade, J. Cicero, Polylactides: properties and prospects of an environmentally benign plastic from renewable resources. Macromol. Symp. 175, 55–66 (2001)

M. Hiljanen-Vainio, P. Varpomaa, J. Seppälä, P. Törmälä, Modification of poly(l-lactides) by blending: mechanical and hydrolytic behavior. Macromol. Chem. Phys. 197, 1503–1523 (1996)

R.M. Rasal, D.E. Hirt, Toughness decrease of PLA–PHBHHx blend films upon surface-confined photo polymerization. J. Biomed. Mater. Res. Part A 88(4), 1079–1086 (2008)

R. Auras, B. Harte, S. Selke, An overview of polylactides as packaging materials. Macromol. Biosci. 4, 835–864 (2004)

N. Bitinis, R. Verdejo, P. Cassagnau, M.A. Lopez-Manchadoa, Structure and properties of polylactide/natural rubber blends. Mater. Chem. Phys. 129, 823–831 (2011)

B. Meng, J. Deng, Q. Liu, Z. Wu, W. Yang, Transparent and ductile poly(lactic acid)/poly(butyl acrylate) (PBA) blends: structure and properties. Eur. Polym. J. 48, 127–135 (2012)

S. Ishida, R. Nagasaki, K. Chino, T. Dong, Y. Inoue, Toughening of poly(L-lactide) by melt blending with rubbers. J. Appl. Polym. Sci. 113, 558–566 (2009)

G. Siqueira, J. Bras, A. Dufresne, Polymers 2, 728 (2010)

D. Puglia, J. Biagiotti, J.M. Kenny, J. Nat. Fibers 1, 23 (2004)

J. Jordan, K.J. Jacob, R. Tannenbaum, M.A. Sharaf, I. Jasuk, Experimental trends in polymer nanocomposites—a review. Mater. Sci. Eng. A Struct. 393, 1–11 (2005)

M. Moniruzzaman, K. Winey, Polymer nanocomposites containing carbon nanotubes. Macromolecules 39, 5194–5205 (2006)

A. Star, J.F. Stoddart, D. Steuerman, M. Diehl, A. Boukai, E.W. Wong, X. Yang, S.W. Chung, H. Choi, J.R. Heath, Preparation and properties of polymer wrapped single-walled carbon nanotubes. Angew. Chem. Int. Ed. 40, 1721–1725 (2001)

F. Ciardelli, S. Coiai, E. Passaglia, A. Pucci, G. Ruggeri, Nanocomposites based on polyolefins and functional thermoplastic materials. Polym. Int. 57, 805–836 (2008)

C. Nakason, A. Kaesaman, K. Eardrod, Cure and mechanical properties of natural rubber-g-poly(methyl methacrylate)–cassava starch compounds. Mater. Lett. 59, 4020–4025 (2005)

C. Nakason, A. Kaesaman, S. Homsin, S. Kiatkamjonwong, Rheological and curing behavior of reactive blending. II. Natural rubber-g-poly(methyl methacrylate)–cassava starch. J. Appl. Polym. Sci. 89, 1453–1463 (2003)

C. Nakason, A. Kaesaman, T. Wongkul, S. Kiatkamjonwong, Rheological and curing properties of reactive blending products of epoxidised natural rubber and cassava starch. Plast Rubber Compos. 30, 154–161 (2001)

S. Hizukuri, Polymodal distribution of the chain lengths of amylopectins, and its significance. Carbohydr. Res. 147, 342–347 (1986)

R. Stute, R.W. Klingler, S. Boguslawski Dipl-Ing, M.N. Eshtiaghi Dipl-Ing, D. Knorr, Effects of high pressures treatment on starches. Starch 48, 11–12 (1996)

A. Imberty, H. Chanzy, S. Perez, A. Buleon, V. Tran, New three-dimensional structure for A-type starch. Macromolecules 20, 2634–2636 (1987)

A. Imberty, S. Perez, A revisit to the three-dimensional structure of B-type starch. Biopolymers 27, 1205–1221 (1988)

F.G. Corvasce, F.A.J. Fourgon, Chemically modified starch reinforced natural rubber composites. EP 1293530 (2003)

T. Tomita, T. Horiguchi, I. Tsumori, Chemically modified starch reinforced natural rubber composites. JP 2005053944 (2005)

C. Wang, Z.L. Pan, P. Zhao, S.B. Fang, Y.J. Li, CN 03109143 (2003)

H. Tang, Q. Qi, Y. Wu, G. Liang, L. Zhang, J. Ma, Reinforcement of elastomer by starch. Macromol. Mater. Eng. 291, 629–637 (2006)

H. Yang, Q. Zhang, M. Guo, C. Wang, R. Du, Q. Fu, Study on the phase structures and toughening mechanism in PP/EPDM/SiO2 ternary composites. Polymer 47, 2106–2115 (2006)

A. Dufresne, J.Y. Cavaille, W. Helbert, New nanocomposite materials: microcrystalline starch reinforced thermoplastic. Macromolecules 29, 7624–7626 (1996)

S. Pichaiyut, S. Wisunthorn, C. Thongpet, C. Nakason. Novel ternary blends of natural rubber/linear low-density polyethylene/thermoplastic starch: influence of epoxide level of epoxidized natural rubber on blend properties. Iran Polym. J. (2016). Doi:10.1007/S/3726-016-0459-z

M. Bootklad, K. Kaewtatip, Biodegradability, mechanical, and thermal properties of thermoplastic starch/cuttlebone composites. Polym. Compos. 36, 1401–1406 (2007)

C. Yokesahachart, R. Yoksan, Effect of amphiphilic molecules on characteristics and tensile properties of thermoplastic starch and its blends with poly(lactic acid). Carbohydr. Polym. 83, 22–31 (2011)

R. Shanks, I. Kong, Thermoplastic Starch, Thermoplastic Elastomers (2012), Rijeka, Croatia, pp. 137–154

M.M. Pang, M.Y. Pun, Z.A.M. Ishak, Degradation studies during water absorption, aerobic biodegradation, and soil burial of biobased thermoplastic starch from agricultural waste/ polypropylene blends. J. Appl. Polym. Sci. 129, 3656–3664 (2013)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Visakh P.M. (2017). Rubber Based Bionanocomposites: Preparation and State of Art. In: Visakh P. M. (eds) Rubber Based Bionanocomposites. Advanced Structured Materials, vol 56. Springer, Cham. https://doi.org/10.1007/978-3-319-48806-6_1

Download citation

DOI: https://doi.org/10.1007/978-3-319-48806-6_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48804-2

Online ISBN: 978-3-319-48806-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)