Abstract

A simple two-compartment in vitro dynamic gastrointestinal digestion system allowing the study of the disintegration of food during digestion has been recently developed at INRA. As a first application, it has been used for understanding the mechanisms of infant formula disintegration in the infant gastrointestinal tract. The developed system was validated by comparing the kinetics of proteolysis obtained in vitro towards in vivo data collected on piglets. Results showed a good correlation between in vitro and in vivo data and prove the physiological relevance of the newly developed system.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

- Two-compartment in vitro dynamic gastrointestinal digestion system

- Disintegration of food

- In vitro

- Digestion

- Infant gastrointestinal tract

1 Origins and Design of the DIDGI® System

At the French National Institute for Agricultural Research (INRA), several groups are trying to improve our understanding of the fate of different foods (dairy, egg, meat, bakery products, etc.) in the gastrointestinal tract. Our first objective is to unravel the mechanisms of food disintegration in the gastrointestinal tract and identify the molecules (nutrients, bioactive compounds, contaminants etc.) that are released during digestion (Barbé et al. 2013). A second objective is to determine how the structure of food matrices affects food digestion and nutrient bioaccessibility and bioavailability (Barbé et al. 2014). Finally, we model digestion and translate this cascade of events into mathematical models (Le Feunteun et al. 2014) in order to design new foods through a reverse engineering approach i.e. starting from the bioactivity we want to deliver to the body and going back to the most adapted structure.

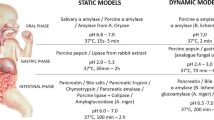

Since dynamic digestion devices are not very available on the market or quite expensive, we decided to build our own system. The system developed had to be cheap, simple, robust and applicable to all kind of foods INRA is working on. This model was built in order to monitor the disintegration and the kinetics of hydrolysis of the food occurring during a simulated digestion. It focuses on the upper parts of the digestive tract, i.e. the stomach and the small intestine. To be physiologically realistic, the computer-controlled system reproduces the gastric and intestinal transit times, the kinetics of gastric and intestinal pH, the sequential addition of digestive secretions and the stirring of the stomach and small intestine contents.

The gastrointestinal digestion system (Fig. 8.1) consists of two consecutive compartments simulating the stomach and the small intestine. Each compartment is surrounded by a glass jacket filled with water pumped using a temperature-controlled water bath. The system is equipped with temperature, pH and redox sensors and variable speed pumps to control the flow of meal, HCl, Na2CO3, bile, enzymes and the emptying of each compartment. Flow rates are regulated by specific computer-controlled peristaltic pumps. Anaerobic conditions can be simulated by purging air with nitrogen. A Teflon membrane with 2 mm holes is placed before the transfer pump between the gastric and the intestinal compartment to mimic the sieving effect of the pylorus in human, as described previously (Kong and Singh 2008).

The computer program was designed to accept parameters and data obtained from in vivo studies in animals or human volunteers, such as the quantity and duration of a meal, the pH curves for the stomach and small intestine, the secretion rates into the different compartments and the gastric and small intestine emptying rates. The system is controlled by software named StoRM for Stomach regulation and monitoring (Guillemin et al. 2010). To control the transit time of the chyme in each compartment, a power exponential equation for gastric and intestinal delivery is used \( \mathrm{f}={2^{-\left(t/\mathrm{t}\;1/2\right)}}^{\beta } \) where f represents the fraction of the chyme remaining in the stomach, t is the time of delivery, t½ is the half time of delivery and β is the coefficient describing the shape of the curve, as described previously (Elashoff et al. 1982).

2 Validation of DIDGI® for the Digestion of Infant Formula

The DIDGI® system is a very recent one. Although several matrices (dairy, meat, fruits and vegetables, emulsions) have been submitted to digestion using the DIDGI® system, only data obtained on the digestion of infant formulas have been published so far (Ménard et al. 2014). In order to demonstrate that this system was physiologically-relevant, a comparison of the in vitro and in vivo digestion of an infant formula was performed. The in vivo trial was conducted on 18 piglets that were fed the infant formula for which the concentration in lipids and proteins was increased compared to a standard one, but the ratio lipids/proteins was kept constant. In parallel, in vitro gastro-intestinal digestion was performed on this enriched infant formula using the newly developed system and the extent of milk proteolysis was monitored and compared to the one obtained in vivo.

2.1 Protocol for the In Vitro Dynamic Digestion of Infant Formula Using the DIDGI® System

Infant formula (150 ml) was introduced into the gastric compartment within a pre-set period of time, i.e. 10 min. The pH values were controlled via the computer by secreting either 0.5 M HCl to decrease the pH in the stomach or 0.1 M Na2CO3 to neutralize the pH in the small intestine.

The dynamic digestive system was set up using parameters taken from the literature that are listed in Table 8.1. The pH curve in the stomach was obtained by combining data from different in vivo experiments on piglets (Moughan et al. 1991; Chiang et al. 2008; Bouzerzour et al. 2012) whereas intestinal pH was kept constant at 6.5. Other parameters like the transit time of the formula in the stomach (determination of t1/2 and β) was obtained from an exhaustive review on human infant gastrointestinal physiological conditions (Bourlieu et al. 2014) and fixed at t1/2 = 70 min or 200 min and β = 1.23 or 2.2 for gastric or intestinal transit time, respectively. Volumes, flow rates of secretions, nature and quantity of enzymes in the different stages of the gastro-intestinal model have been described previously (Minekus et al. 1995; Blanquet et al. 2004; Bouzerzour et al. 2012) based on results of in vivo experiments. Digestive enzymes and bile were diluted in 150 mM NaCl, pH 6.5. After rehydration, all the digestive enzymes were kept on ice throughout the experiment in order to avoid autolysis. Digestion experiments were performed in triplicates. Samples were collected during the digestion in each compartment at 30, 60, 90, 120 and 210 min after ingestion. Before being frozen at −20 °C, phenylmethanesulfonyl fluoride was added at 0.37 g/kg of digested sample in order to inhibit proteolysis.

2.2 In Vivo Digestion of Infant Formula on Piglets

An in vivo study on piglets was conducted in parallel in accordance with the guidelines formulated by the European Community for the use of experimental animals (EU Directive 2010/63/EU). Eighteen piglets [Pietrain × (Large White × Landrace)] were separated from their mothers after 2 days and fed for 26 days with the formula using an automatic milk feeder, as described previously (Bouzerzour et al. 2012). The experimental design was a complete block design with 1 × 3 factorial arrangement of 1 diet and 3 slaughter times after the last meal (30 min, 90 min and 210 min). The daily net energy ration of 1,450 kJ/body weight (BW)0.75 was partitioned into ten meals automatically distributed during the day. Body weights were recorded weekly, and feeding schedules were adjusted accordingly. At the age of 28 days, piglets were allotted in three groups according to their slaughter times after the last meal: 30 min, 90 min and 210 min. They were slaughtered by electronarcosis immediately followed by exsanguination. Immediately afterwards, the digestive tract was removed, dissected and samples were collected from the stomach to the ileum.

The total content of each segment was collected, dispersed and pH was measured. Sodium benzoate and phenylmethanesulfonyl fluoride (10 and 0.37 g/kg of content, respectively) were added to each digested sample in order to avoid further protein breakdown. All effluents were stored at −20 °C until further analyses.

2.3 Comparison In Vitro/In Vivo Data

The evolution of the volume emptied from the stomach into the small intestine, the volume remaining in the stomach and the total volume of gastric content (emptied + remaining) monitored during three independent digestion experiments is represented on Fig. 8.2. The rapid increase in the total volume during the first 10 min of digestion corresponds to the ingestion of the infant formula. Subsequently, its increase is due to the injection of gastric secretions.

The emptied volume follows the gastric transit described by the Elashoff’s equation (Elashoff et al. 1982). Figure 8.2 also shows an excellent reproducibility between experiments since the curves of the replicates are similar in the gastric compartment. In the intestinal compartment, the reproducibility was also excellent (data not shown). Measuring all the volumes coming in and out of the two compartments allowed an assessment of the reliability of the system by comparing the values obtained by the system with those predicted by the software. The initial pH of the formula was 6.5. The pH regulation started only 5 min after the beginning of the experiment. Indeed, a minimum volume of c.a. 15 ml is needed for the pH electrode to give reliable measurements. Then pH followed the equation of the gastric acidification curve. The decrease in pH throughout the experiment is due to the addition of hydrochloric acid to the gastric compartment. After 210 min of digestion, gastric pH reached 3.10; at this stage, only 40 mL were present in the stomach mainly consisting of simulated gastric fluid.

Volumes of the stomach content observed in vitro with the dynamic digestion system were compared to the ones observed in vivo in piglets (Fig. 8.3). No significant differences were observed 30, 90 and 210 min after ingestion confirming that the parameters chosen for mimicking the gastric transit of infant formula in vitro were physiologically relevant.

Evolution of caseins (Fig. 8.4a) and β-lactoglobulin (Fig. 8.4b) throughout in vitro and in vivo digestion, as determined by ELISA, was compared. Results showed that the kinetics of hydrolysis of both proteins during in vitro and in vivo digestion were similar. The proportion of immunoreactive caseins appeared not to be significantly different between both experiments for samples collected in the stomach as well as in the small intestine after 30, 90 and 210 min of digestion (Fig. 8.4a). Similarly, the percentage of immunoreactive β-lactoglobulin showed no significant differences for samples collected in vivo and in vitro in the stomach after 30, 90 and 210 min. However, the percentage of immunoreactive β-lactoglobulin in the small intestine was significantly higher in vitro than in vivo. The correlation coefficient, between in vitro and in vivo ELISA determination for caseins and β-lactoglobulin was 0.987 (p < 0.001), proving a good agreement between in vitro and in vivo proteolysis during digestion.

3 Advantages, Disadvantages and Limitations

Some advantages and limitations of the DIDGI® are provided in Table 8.2.

4 Conclusion and Prospects

We present here the development of a simple and new dynamic digestion system, DIDGI® that has been validated against in vivo (porcine) data for the digestion of infant formula. The system is currently being applied to study (1) the digestion of human milk, dairy gels and emulsions, cheese, and (2) the survival of food microorganisms in the gastro-intestinal tract. The results obtained so far are quite promising. Some improvements have recently been applied to the system: it now has three compartments (stomach, duodenum and jejunum + ileum) instead of two; dialysis membranes will soon be added to the system to mimic absorption; the pump allowing the bolus to enter the stomach has been modified to allow the introduction of solid matrices (meat, bread, fruits and vegetables).

References

Barbé F, Ménard O, Le Gouar Y, Buffière C, Famelart MH, Laroche B, Le Feunteun S, Dupont D, Rémond D (2013) The heat treatment and the gelation are strong determinants of the kinetics of milk proteins digestion and of the peripheral availability of amino acids. Food Chem 136(3–4):1203–1212

Barbé F, Ménard O, Le Gouar Y, Buffière C, Famelart M-H, Laroche B, Le Feunteun S, Rémond D, Dupont D (2014) Acid and rennet gels exhibit strong differences in the kinetics of milk protein digestion and amino acid bioavailability. Food Chem 143:1–8

Blanquet S, Zeijdner E, Beyssac E, Meunier JP, Denis S, Havenaar R, Alric M (2004) A dynamic artificial gastrointestinal system for studying the behavior of orally administered drug dosage forms under various physiological conditions. Pharm Res 21(4):585–591

Bourlieu C, Menard O, Bouzerzour K, Mandalari G, Macierzanka A, Mackie A, Dupont D (2014) Specificity of infant digestive conditions: some clues for developing relevant in vitro models. Crit Rev Food Sci Nutr 54:1427–1457

Bouzerzour K, Morgan F, Cuinet I, Bonhomme C, Jardin J, Le Huerou-Luron I, Dupont D (2012) In vivo digestion of infant formula in piglets: protein digestion kinetics and release of bioactive peptides. Br J Nutr 108(12):1–10. doi:10.1017/S000711451200027X

Chiang C, Croom J, Chuang S, Chiou P, Yu B (2008) Development of a dynamic system simulating pig gastric digestion. Asian-Australasian J Anim Sci 21(10):1522–1528

Elashoff JD, Reedy TJ, Meyer JH (1982) Analysis of gastric-emptying data. Gastroenterology 83(6):1306–1312

Guillemin H, Perret B, Picque D, Menard O, Cattenoz T (2010) Logiciel StoRM - stomach and duodenum regulation and monitoring. IDDNFR001230009000RP201000031235:290

Kong F, Singh RP (2008) Disintegration of solid foods in human stomach. J Food Sci 73(5):R67–R80. doi:10.1111/j.1750-3841.2008.00766.x

Le Feunteun S, Barbé F, Rémond D, Ménard O, Le Gouar Y, Dupont D, Laroche B (2014) Impact of the dairy matrix structure on milk protein digestion kinetics: mechanistic modelling based on mini-pig in vivo data. Food Bioprocess Technol 7(4):1099–1113

Ménard O, Cattenoz T, Guillemin H, Souchon I, Deglaire A, Dupont D, Picque D (2014) Validation of a new in vitro dynamic system to simulate infant digestion. Food Chem 145:1039–1045

Minekus M, Marteau P, Havenaar R, Huisintveld JHJ (1995) A multicompartmental dynamic computer-controlled model simulating the stomach and small-intestine. Altern Lab Anim 23(2):197–209

Moughan PJ, Cranwell PD, Smith WC (1991) An evaluation with piglets of bovine-milk, hydrolyzed bovine-milk, and isolated soybean proteins included in infant milk formulas.2. Stomach-emptying rate and the postprandial change in gastric Ph and milk-clotting enzyme-activity. J Pediatr Gastroenterol Nutr 12(2):253–259

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is distributed under the terms of the Creative Commons Attribution Noncommercial License, which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Copyright information

© 2015 The Author(s)

About this chapter

Cite this chapter

Ménard, O., Picque, D., Dupont, D. (2015). The DIDGI® System. In: Verhoeckx, K., et al. The Impact of Food Bioactives on Health. Springer, Cham. https://doi.org/10.1007/978-3-319-16104-4_8

Download citation

DOI: https://doi.org/10.1007/978-3-319-16104-4_8

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-15791-7

Online ISBN: 978-3-319-16104-4

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)