Abstract

It has been shown that surface microtexturing is useful for improving lubrication. It offers strong reductions in the friction coefficient under operation conditions which compromise the maintenance of full film lubrication. To study the influence of texturing in the reduction of the friction coefficient, an Artificial Intelligence algorithm will be used. Its performance will be optimized. Afterwards, the algorithm will be applied to a new set of textured surfaces with the objective of finding the optimal one, that is, the one capable of reducing friction under different operating conditions. The selection of the optimal texturing will be based on the Weighted Mean Value of the friction coefficient (WMPT), a metric that was specifically created for this purpose.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Controlled surface microtexturing is an interesting option to reduce friction, since it can improve lubrication conditions, especially when the operation of the system compromises the maintenance of full film lubrication [1, 2]. Therefore, the main effect takes place in the transition from full film lubrication to mixed lubrication conditions, as is the case of machine elements that operate with high load and/or low speed, such as bearings, gears, etc. There are numerous references that experimentally quantify the effect of dimple-based microtexturing on lubricated friction, through the analysis of several types of patterns, geometries, texturing densities, and manufacturing methods [1, 3,4,5]. Regarding the mechanisms that reduce friction, the literature describes the capability of texturing to form lubricant microreservoirs [6], which allow the surfaces to be separated through the formation of local hydrodynamic wedges [2, 7]. Although there are study sources, attempts to model the operation of textured surfaces are relatively scarce, except for those presented in references [8, 9] and some others. The complexity of the interactions between textured surfaces makes it difficult to model their performance. To address this problem, the use of Artificial Intelligence (AI) algorithms can be of great benefit since they ease the handling of all the experimental information available. These algorithms can be applied to predict the friction between textured surfaces and to optimize their performance, without the need to model the complex phy-sical phenomena that take place in the contact. In fact, AI has been used successfully in many tribological applications as is gathered in references [10, 11]. Echávarri Otero et al. have investigated the use of neural networks to predict the lubricated friction coefficient in textured point contacts using the Matlab Deep Learning Toolbox [1].

The present article analyses the use and optimization of an Artificial Intelligence (AI) algorithm for predicting the friction coefficient (CoF) in lubricated contacts with different microtexturing patterns. Then, it will be used to find the textured surface that reduces the friction coefficient to a greater extend under a range of operating conditions.

2 Methodology

2.1 Obtaining the Initial Data

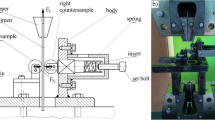

For this study, a series of friction tests carried out on the Mini-Traction Machine (MTM) are used as data set. 21 microtextured copper test samples with different geometric patterns are used, in contact with a ¾” diameter (19 mm) steel ball, resulting in a point contact. The lubricant is a PAO-6 base oil. The test conditions are:

-

Slide-to-Roll ratio, SRR (%): it is the quotient between the sliding speed and the average speed: 5, 10, 20 50, 75 and 100%.

-

Average speed (mm/s): value range from 100 to 3500 mm/s.

-

Normal contact load (N): 5 and 20 N.

-

Lubricant bath temperature (ºC): 40 and 80 ºC.

-

The geometric characteristics of the microtextured patterns are as follows:

-

Shape: The data set includes specimens with circular, elliptical and radial microtexturing pattern, as well as untextured samples. This variable is categorical and allows differentiating between each type of microtexture.

-

Dimension 1 (μm): radius for circular textures or minor axis length in the sliding direction for elliptical samples or groove width for radial pattern. Values between 0–350 μm.

-

Dimension 2 (μm): radius for circular textures or major axis length in the sliding direction for elliptical samples or groove width for radial pattern. Values between 0–11000 μm.

-

Texturing density (%): surface area that has been textured relative to the total area. Values between 0–25%.

-

Depth (μm): depth of the pattern. Values between 0–185 μm.

-

Roughness (μm): Average surface roughness of the test sample before texturing. Specimens with 0.007 and 0.1 μm of Ra roughness have been used.

-

Regarding the tests with these microtextured samples, 9 pairs of average speed-friction coefficient values are obtained, for each Stribeck curve. The curves for each sample correspond to a typical performance of the Stribeck curves in reference [1].

2.2 Artificial Intelligence Algorithm, Data Preprocessing, Training and Evaluation

In order to have a larger data set, the first goal has been to carry out a data augmentation. To this end, the UnivariateSpline function available in the Scipy python library has been used. A total of 160 pairs of values of friction coefficient and average speed are obtained.

Machine learning algorithms present optimized performance when the values are in an identical and small range, the second stage in data preprocessing is the scaling of each variable in the range of values from −1 to 1. To achieve this, the MinMaxScaler function available in the SciKitLearn library is used [12, 13]. Then, the data set formed by 40320 data is divided into two sets using a pseudorandom function by defining a value called “seed”:

-

Training data set: is formed by 90% of the data set.

-

Validation set: is formed by the remaining 10% of the data set. From these data, the prediction of the network can be evaluated through different evaluation metrics. After this, the algorithms hyperparameters are modified to optimize its performance.

The case study is a supervised learning approach since the values of the output variable, the friction coefficient, to be predicted are already known. The input variables are these shown in Sect. 2.1.

The algorithm has been trained following an iterative method, in order to optimize their operation from the evaluation of their performance according to mathematical metrics used on the training and validation data set. The metric used to evaluate the algorithm is the mean squared error quality metric (MSE).

The algorithm selected for this study is a Sequential Neural Network, which is a model made up of artificial neurons connected to each other and grouped in the form of layers. The Back Propagation algorithm is selected for carrying out the learning process.

2.3 Optimal Microtexturing Prediction.

Once the best algorithm for predicting the CoF has been chosen, we proceed to predict this coefficient with new microtexturing patterns which are different from those that form the training and validation set. Selecting the microtextured surface that achieves the lowest friction for the two studied loads and six Slide-to-Roll ratios can be an overly complex task. For this reason, it is decided to apply the calculation of a weighted mean value of the friction coefficient per test (WMPT), as a method of comparison and selection. In the calculation of WMPT, “test” alludes to a Stribeck curve. This weighted mean value is chosen to give more significance to the lowest average speeds (from 100 to 1000 mm/s), since the microtextures are expected to improve the behavior at these speeds, in which the test conditions are more severe and mixed lubrication is achieved.

The WMPT value is calculated for each test, considering the 9 predicted friction coefficient values f_i for the following average speeds: 100, 250, 500, 1000, 1500, 2000, 2500, 3000 and 3500 mm/s in a weighted way, according to Eq. (1). The values c1 and c2 have been stablished as 0.15 and 0.08 respectively. Each test sample is tested at 2 loads and 6 different SRR for each load, a total of 12 tests are obtained and the WMPT metric is calculated on each of them. As a control test, an untextured sample is tested and the WMPT metric is calculated again for each of the tests, which is called WMPTc. Then the WMPT of each test is compared with the value of the control test (WMPTc). With this result, a counting procedure is followed using Eq. 2:

Finally, the sum of the x values of each test sample is performed, thus obtaining a criterion that allows deciding which type of microtextured surfaces reduce friction on average for the combinations of load and SRR.

3 Results

Sequential neural network is a deep learning algorithm, a Machine learning subset which is typically used to solve highly complex problems. The neuronal algorithm is built with the so-called Dense layer of Keras programming library [12, 13]. It has been trained with different network configurations, using different amounts of neurons and hidden layers. The optimal parameters and the obtained MSE are shown in Table 1.

The MSE is very low, revealing an accurate prediction of the friction coefficient on the validation data. Furthermore, the MSE value for the training and validation data sets becomes very similar in last training epochs. Thus, it is concluded that no overfitting is presented. A minimum value of 1.44e−04 can be found in epoch 491.

Once the Neural Network has been chosen as the appropriate algorithm, by using it and applying the method described in Sect. 2.3 it is made the prediction and selection of the optimal microtextured surface. To achieve this, a new data set of microtextured test samples is created. The different geometric variables that define a microtexture are in the range of values studied. The total number of new microtextured surfaces is 6783. In this way, the tests results with the same testing conditions shown in Sect. 2.1 are obtained for each of the different test samples.

According to the friction coefficient data predicted using the Neural Network, it is determined that the optimal design is a circular shape with dimension 1 and 2 equal to 100 μm; texturing density 8%; depth 110 μm and Ra 0.007 μm. The sum of x (from Eq. 2) is equal to 7. Figure 1 compares the results of a series of six predictions obtained for the optimal sample with an untextured sample. This graph shows that the friction values predicted by the Neural Network are reduced with respect to the untextured test sample, in all SRR conditions for a 20 N load. Also, the texturing effect is greater at low speeds, where theoretically the presence of textures should lead to more favorable lubrication conditions.

The results show that the texturing density and geometry predictions follow the trend of other empirical studies [1, 6]. It seems logical that greater depths allow a greater friction reduction, since the microtextures act as lubricant reservoirs. However, there is no overall optimal value. Rosekranz et al. [14] obtained that the optimal depth was between 25 and 50 μm. While Echávarri et al. [1] have concluded that the optimal depth for elliptical textures is around 78 μm, increasing the friction drop as texture depth increases. Therefore, tests must be performed to verify this effect.

4 Conclusions

This study has shown the use of Artificial Intelligence algorithms for predicting the friction coefficient in lubricated contacts with microtextured surfaces.

The architecture of the Neural Network is formed with one hidden layer of 64 neurons. The predictions can be obtained on any computer in a few seconds. This gives to the Neural Network a notable advantage over complex numerical simulations.

The predictions made by the Neural Network on the friction coefficient show a Stribeck curve with a similar shape to the experimental data, demonstrating that the network captures the texturing effect on the Stribeck curve. Furthermore, if we compare all the Stribeck curves of the textured test sample in Fig. 1 with the untextured sample, they show an improvement in friction. Finally, it is worth mentioning that the network can accurately predict the influence of the slide-to-roll ratio, allowing the results to be generalized for other slide-to-roll ratio values within the studied range.

In the future, the authors will compare the results of the Neural Network prediction with experimentation to verify the friction reduction.

References

Echávarri, J., de la Guerra, E., Bellón, I., Chacón, E.: Optimizing the design of textured surfaces for reducing lubricated friction coefficient. Lubr. Sci. 29(3), 183–199 (2017)

Gohar, R., Rahnejat, H.: Fundamentals of Tribology, 3rd edn. World Scientific Publishing Europe (2019)

Kovalchenko, A., Ajayi, O., Erdemir, A., Fenske, G., Etsion, I.: The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 38, 219–225 (2005)

Gachot, C., Rosenkranz, A., Hsu, S.M., Costa, H.L.: A critical assessment of surface texturing for friction and wear improvement. Wear 372–373, 21–41 (2017)

Xu, Y., et al.: Characterization of the tribological behavior of the textured steel surfaces fabricated by photolithographic etching. Tribol. Lett. 66, 55 (2018)

Wakuda, M., Yamauchi, Y., Kanzaki, S., Yasuda, Y.: Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 254(3), 356–363 (2003)

Predescu, A., Pascovici, M.D., et al.: Friction evaluation of lubricated laser-textured surfaces. Lubr. Sci. 22(10), 431–442 (2010)

Ronen, A., Etsion, I., Kligerman, Y.: Friction-reducing surface-texturing in reciprocating automotive components. Tribol. Trans. 44, 359–366 (2001)

Marian, M., Grützmacher, P., Rosenkranz, A., Tremmel, S., Mücklich, F., Wartzack, S.: Designing surface textures for EHL point-contacts - transient 3D simulations, meta-modeling and experimental validation. Tribol. Int. 137, 152–163 (2019)

Marian, M., Tremmel, S.: Current trends and applications of machine learning in tribology—a review. Lubricants 9(9), 86 (2021)

Echávarri, J., et al.: Artificial neural network approach to predict the lubricated friction coefficient. Lubr. Sci. 26, 141–162 (2014)

García Moltó, J.J.: Inteligencia artificial aplicada al análisis tribológico de texturizados superficiales con Python. Bachelor thesis, Universidad Politécnica de Madrid (2021)

Bobadilla, J.: Machine Learning y Deep Learning: Usando Python, Scikit y Keras. Ra-Ma Editorial (2021). 9789587921465

Rosenkranz, A., Szurdak, A., Garchot, C., Hirt, G., Mücklich, F.: Friction reduction under mixed and full film EHL induced by hot micro-coined surface patterns. Tribol. Int. 95, 290–297 (2016)

Acknowledgments

The authors are grateful for the collaboration of the Repsol Tech lab (Mostoles, Spain) in the preliminary experimental phase of this study.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Franco-Martínez, F., Moltó, J.J.G., Otero, J.E., Tanarro, E.C., Díaz-Lantada, A. (2023). Using Artificial Intelligence to Predict Lubricated Friction in Microtextured Mechanical Contacts. In: Vizán Idoipe, A., García Prada, J.C. (eds) Proceedings of the XV Ibero-American Congress of Mechanical Engineering. IACME 2022. Springer, Cham. https://doi.org/10.1007/978-3-031-38563-6_63

Download citation

DOI: https://doi.org/10.1007/978-3-031-38563-6_63

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-38562-9

Online ISBN: 978-3-031-38563-6

eBook Packages: EngineeringEngineering (R0)