Abstract

Surface roughness is an essential property in the manufacturing industry to assess the quality of its products after finishing operations. However, the evaluation of surface quality in wood products usually depends on the subjective inspection of the operators, which implies a high variability in the final quality of the pieces. This study proposes a new method to estimate roughness parameters by applying algorithms on images of wood parts processed by robotic sanding. For this purpose, this article presents a hybrid approach based on features using the co-occurrence matrix applied to greyscale images processed with five edge detection algorithms. For the evaluation of the performance of this method, the researchers correlated five features for each edge detection algorithm with standard surface roughness parameters, obtaining high correlations. The results of this study constitute a first step in implementing the proposed method in inspection systems for optical roughness measurement of wood products in automated industrial environments.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Multiple studies are underway to automate the sanding operation using industrial robots [1]. Advances in this area require further knowledge and modelling of the robotic sanding process, considering the operating conditions and material properties. According to Gurau [2], the results of surface roughness evaluation on processed wood vary depending on many factors, such as: wood species, cut direction, structural elements of the wood, moisture content, operating conditions and measuring instrument.

Wood has a strong anisotropy, making the process’s influence on the piece’s roughness challenging to investigate. However, Medium Density Fibreboards (MDF) are more homogeneous materials, with no distinction in the fibre directions [3]. This characteristic makes it an appropriate material to investigate the influence of the operating conditions on the surface quality, reducing the variability in the results.

Gurau & Irle [4] reviewed surface roughness evaluation methods, indicating that wood products have no standardised procedure for calculating the amplitude parameters. A less explored field is non-conventional techniques for estimating wood roughness based on two-dimensional images.

Techniques based on two-dimensional images make possible fast, low-cost results, and allow easy integration into inspection lines or intelligent manufacturing devices. Ghodrati et al. [5] proposed a roughness evaluation method for plastic parts using edge detection algorithms in images, showing a high correlation between the features extracted from the images and the standardised roughness parameters, but it also presented variations at different resolutions. Gadelmawla [6] used features extracted from the grey-level co-occurrence matrix to estimate the surface roughness of turned parts. However, this technique is highly dependent on the illumination conditions.

Based on the background, there still needs to be a consensus on applying machine vision algorithms to evaluate surface roughness. There is also a gap in the literature on applying this algorithm in wood and its derivatives. To reduce this gap, we propose to evaluate the application of image-based algorithms to estimate surface roughness parameters in wood parts processed by robotic sanding.

2 Methodology

We proposed a method based on features using the grey-level co-occurrence matrix, applied to images processed with edge detection algorithms to reduce illumination effects. Then we evaluate Pearson’s r between the features and the roughness parameters.

2.1 Experimental Trials

The robotic sanding station consists of a servomotor-driven sander integrated with a structure mounted on the flange of a UR10e collaborative robot. The sanding station processed 15 MDF specimens (180 × 110 × 15 [mm3]) with the same operating conditions, except for sanding grit size, with levels P80, P120 and P240. The three types of circular sandpaper were 3M™ Cubitron™ II Hookit™ 127 [mm] diameter, with perforations for particle suction. The general conditions of the experimental trials were:

-

a normal force of 20 [N], controlled by the collaborative robot;

-

a rotational speed of 2000 [rpm] on the servomotor; and,

-

a feed rate of 0.02 [m/s], defined through a linear movement of the robot.

The total number of specimens was subdivided into three groups of five: the first group was processed with sandpaper P80, the second with P120 and the third was processed with two passes, one P120 and one finer pass P240, considering the need for incremental sanding when using finer grits.

2.2 Roughness Measurement

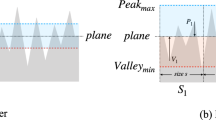

We used a Mitutoyo SJ-310 contact roughness profilometer to measure surface roughness (three measurements at the centre of each specimen in the feed direction) to calculate roughness parameters (\({R}_{a}\), \({R}_{sm}\), \({R}_{sk}\), \({R}_{z}\), and \({R}_{p}\)) according to ISO 21920-2 [7].

The mechanical profile was processed in MATLAB (version R2021b). First, we applied a Gaussian S-filter to remove the small lateral scale components (short wavelength), with nesting index \({N}_{i\mathrm{s}}=0.008 \left[\mathrm{mm}\right]\). Then, we used the F-operation, consisting of the adjustment and subtraction of a sixth-order polynomial, to remove the profile shape [8]. Finally, we applied a Gaussian L-filter, which removes the large lateral scale components (long wavelength) with nesting index \({N}_{i\mathrm{c}}=2.5 \left[\mathrm{mm}\right]\).

The uncertainty was estimated by pooling the three measurements of the five processed specimens with the same grit number, calculating 95% confidence intervals using a Student’s t-distribution.

2.3 Image Acquisition and Processing

Image acquisition was executed in a darkroom with side LED illumination, with a SONY STL-A58 camera with DT 3.5–5.6/18–55 SAM II lens, focal length 30 mm, aperture F14, exposure time 10 s, ISO 100, parallel to the specimen surface at 400 mm. After capture, images were cropped in the central area of the MDF specimen with a size of 78 × 676 px, equivalent to approx. 4.5 × 39 mm2. The processing included three steps:

-

Step 1. Edge detection. Edge detection algorithms typically consider three stages: a filtering stage to remove noise; an enhancement stage to facilitate edge detection based on intensity changes; and a detection stage with a thresholding criterion to discern between points that are edges and those that are not. This work will only apply the enhancement stage because using a filter or threshold could reduce the relevant information describing the quality of the surface. We used five enhancement algorithms, three based on the first derivative of the image intensity (Roberts, Sobel, and Prewitt) and two on the second derivative (Laplacian and Laplacian of Gaussian). The derivatives are approximated by differences using convolution masks [9].

-

Step 2. Co-occurrence Matrix. The grey-level co-occurrence matrix (GLCM) [10] is widely used to analyse texture in images, it is a second-order statistical technique that estimates the probability of spatial relationship between two pixels. The co-occurrence matrix is added with its transposed, resulting in a symmetric matrix, which is then normalised. It considers a co-occurrence matrix with a maximum of 8 levels and a displacement vector of \({\varvec{d}}=\left(\mathrm{1,0}\right)\), perpendicular to the sanding marks.

-

Step 3. GLCM Features. The features are obtained according to the definitions of [10]. The five features are: Uniformity of energy (U), Contrast (C), Homogeneity (H), Correlation (Autocorrelation in this paper) (A) and Entropy (S).

3 Results

3.1 Surface Roughness

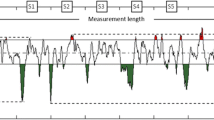

In the results, Fig. 1 shows three roughness profiles obtained with the contact roughness profilometer for each sandpaper grit and the amplitude distribution of each profile. It is possible to appreciate the reduction of profile heights as the grit size increases and the amplitude distribution that reduces its dispersion. Figure 2 shows the roughness parameter mean for each group of specimens sanded with different grit sizes. All roughness parameters show a decrease for finer grit sizes. Parameters \({R}_{a}\), \({R}_{z}\) and \({R}_{p}\), which describe the roughness profile height, present a reduction of the confidence intervals as finer grit is applied. This does not occur with \({R}_{sm}\), and neiher with the skewness \({R}_{sk}\) increases its confidence intervals with finer grits.

3.2 Image Processing

We applied five edge detection algorithms to each image according to the methodology. Figure 4 shows the result after processing one image corresponding to a piece sanded with the coarser grit sandpaper (P80). As the image section corresponds to the central area of the wooden specimen, streaks resulting from the tangential speed of sanding pad rotation can be distinguished perpendicular to the operation’s feed. Figure 3 shows feature means extracted from the GLCM matrix with different edge detection algorithms for each grit size.

In the case of the images resulting from the application of Roberts and the Laplacian algorithms, it is possible to distinguish a lower light intensity. We obtain a higher contrast in images enhanced with Laplacian of Gaussian algorithm.

Figure 4 shows an overlap in confidence intervals between P80 and P120 sandpaper trials where the means do not show a relevant variation in both sandpaper grit size levels. However, this does not occur with P240 sandpaper trials, in which the mean value is distinguishable from the mean values of the other two groups.

3.3 Correlations

The Pearson’s r between the features obtained from images processed with edge detection algorithms and the roughness parameters are presented in Table 1. These results show high correlation levels using edge detection algorithms combined with GLCM features.

When analysing the results, the highest correlations occur using the Roberts edge detection algorithm, while the best-evaluated feature corresponds to Contrast. When calculating the mean of the correlations in absolute value for each edge detection algorithm, Roberts’s algorithm has the highest result with a mean correlation of 0.93. For the features extracted from the GLCM matrix, the highest average correlation occurs in Contrast with 0.90. Equally, the Roberts algorithm and the Contrast feature have the highest absolute correlations above 0.90.

Although the high correlations suggest that the method proposed in this work is suitable for assessing the roughness of sanded MDF parts, further tests with images at different resolutions and illumination modes are needed. In addition, the methodology needs to be repeated in other areas of the specimen surface to assess whether the behaviour is the same. Another relevant aspect necessary to evaluate are the configurations of the GLCM hyperparameters, such as the displacement vector and the number of levels.

4 Conclusion

This work studied a new surface roughness evaluation method employing images of the surface of sanded MDF specimens. We obtain high correlations with the standardised roughness parameters, suggesting that the Roberts algorithm and the Contrast feature are suitable for evaluating the surface quality of sanded wooden parts.

Before establishing models to obtain roughness parameters based on the proposed methodology, it is necessary to optimise the vision system and evaluate the algorithms’ sensitivity with different resolutions and illumination conditions. However, based on the current results, we realised that this methodology based on the capture and processing of two-dimensional images has the potential to improve performance and quality control in the wood sanding industry.

References

Wen, Y., Pagilla, P.R.: A novel 3D path following control framework for robots performing surface finishing tasks. Mechatronics 76(December 2020), 102540 (2021)

Gurau, L.: Testing the processing-induced roughness of sanded wood surfaces separated from wood anatomical structure. Forests 13(2) (2022)

Csanády, E., Magoss, E.: Mechanics of Wood Machining. Springer, Cham (2013). https://doi.org/10.1007/978-3-030-51481-5

Gurau, L., Irle, M.: Surface roughness evaluation methods for wood products: a review. Curr. For. Rep. 3(2), 119–131 (2017). https://doi.org/10.1007/s40725-017-0053-4

Ghodrati, S., Mohseni, M., Gorji Kandi, S.: Application of image edge detection methods for precise estimation of the standard surface roughness parameters: polypropylene/ethylene-propylene-diene-monomer blend as a case study. Meas. J. Int. Meas. Confed. 138, 80–90 (2019)

Gadelmawla, E.S.: Estimation of surface roughness for turning operations using image texture features. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 225(8), 1281–1292 (2011)

ISO 21920-2:2021(en): Geometrical product specifications (GPS)—Surface texture: Profile—Part 2: Terms, definitions and surface texture parameters (2021). https://www.iso.org/standard/72226.html

Piratelli-Filho, A., Sternadt, G.H., Arencibia, R.V.: Removing deep valleys in roughness measurement of soft and natural materials with mathematical filtering. Cienc. Eng. Sci. Eng. J. 21(2), 29–34 (2012)

Ramesh, J., Kasturi, R., Schunck, B.: Machine Vision. McGraw-Hill, Inc. (1995)

Haralick, R.M., Shapiro, L.G.: Computer and Robot Vision, 1st edn. Addison-Wesley Publishing Company (1992)

Acknowledgements

We are very grateful to ANID Chile for funding the projects FONDEF IT21i0069 and VIU22P0027, and we also thank the support of 3M Chile and Eng. Pablo Sanhueza.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Iglesias, F., Aguilera, A., Padilla, A., Madaf, M., Diez, E. (2023). Optical Evaluation of Surface Roughness in Wood Parts Processed by Robotic Sanding. In: Vizán Idoipe, A., García Prada, J.C. (eds) Proceedings of the XV Ibero-American Congress of Mechanical Engineering. IACME 2022. Springer, Cham. https://doi.org/10.1007/978-3-031-38563-6_52

Download citation

DOI: https://doi.org/10.1007/978-3-031-38563-6_52

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-38562-9

Online ISBN: 978-3-031-38563-6

eBook Packages: EngineeringEngineering (R0)