Abstract

Small-scale wind turbines can play an important role in the energy transition by providing distributed generation in urban and rural areas. They can help decrease the reliance on traditional forms of energy generation, such as fossil fuels, which can have negative environmental impacts. Thereby, this study aims to implement and complement a computational fluid dynamics (CFD) methodology for predicting the aerodynamic performance of a H-Darrieus Vertical Axis Wind Turbine (VAWT). The analysis of dimensionless numbers, such as Grid-reduced Vorticity (GRV) and Reference Courant Number (Co*), is used to indicate the suitability of spatial and temporal discretizations. Results for Power Coefficient (Cp) agreed with data from the literature and were associated with corresponding GRV and Co* values. It was also identified that incorporating the evaluation and analysis of dimensionless numbers as simulation parameters can guide methodology settings and significantly reduce simulation time compared to conventional methods such as mesh independence studies.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Small-scale wind power systems are increasingly focused on Vertical Axis Wind Turbines (VAWT) due to their improved performance in turbulent conditions compared to Horizontal Axis Wind Turbines (HAWT). Particularly, the H-Darrieus VAWT solution has received significant attention due to benefits such as low wind speed and omnidirectional operation. Equations 1 and 2 express the most common operational and performance parameters of this type of turbomachinery, Tip Speed Ratio (TSR) and Power Coefficient (Cp).

where T is the torque generated by the turbine, ω is the angular velocity, ρ the specific mass of the air, A the frontal area swept by the rotor, U∞ the undisturbed wind speed and R the radius of the rotor.

Computational fluid dynamics (CFD) simulations are valuable tools for predicting wind turbine performance. It reduces the need for physical testing, but sometimes the computational cost can be high or even prohibitive [1, 2]. Regarding H-Darrieus VAWT, 2D simulations are reliable but require solving an unsteady flow, which increases computational cost. Proper simulation setup is crucial for balancing accuracy and computational time. This study proposes a simplifying methodology for a CFD simulation of a three-bladed H-Darrieus VAWT by using dimensionless numbers to assess discretization and simulation stability.

2 Methodology

Simulations were run on a workstation with Intel Xeon E-2236 6-core processors. The model set up followed article [3], where authors carried H-Darrieus VAWT simulation using ANSYS Fluent ®. Convergence criteria was based on Cp variability during turbine rotation and the total cpu-clock time was recorded. Aerodynamic performance results were associated to dimensionless numbers Grid-Reduced Vorticity and Reference Courante Number Co* [4] which indicating mesh and time step suitability, respectively.

Equation 3 represents the dimensionless Courant number (Co):

where V is the necessary velocity for a particle to cross an element of size Δx, and Δt is the time-step adopted in the simulation. For Co*, Δx must represent the perimeter of the rotor blade divided by the number of elements that the discrete and V the peripheral velocity of the blade. According to [3, 4], the recommended value of Co* for turbomachinery should be less than 10.

Equation 4 represents the dimensionless number GRV:

where ωv represents the vorticity, V0 the local velocity and L0 the representative length or local element size. Authors of [4] recommends GRV values of up to 0.01 in the critical regions of the flow, such as near the blades and in areas of vortex shedding.

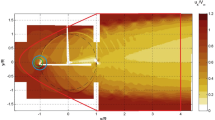

2.1 Computational Domain

Figure 1 shows the computational domain, including auxiliary lines, boundary conditions, and their locations. The rotor has an 850 mm radius (Rturb) and 246 mm chord length (c) of cambered NACA0018. The domain comprises a rectangular stationary zone (SZ) which surrounding a circular rotating zone (RZ). Blade position along its circular path is represented by azimuthal angle (θ).

2.2 Spatial Discretization

Non-structured triangular elements mesh was generated, except for the use of quadrilateral elements in the near-wall regions of blade surfaces. Sizing controls tools were utilized on auxiliary lines to regulate element size, ensuring Skewness and Orthogonal Quality mesh metrics were maximum 0.6 and minimum 0.5 respectively. Figure 2 displays mesh details.

2.3 Modelling setup

The ANSYS Fluent® solver software was configured with a 2nd order upwind scheme for spatial discretization and a bounded 2nd order implicit scheme for temporal discretization. The k-ω SST turbulence model, which requires a y+ value close to 1, was found to be the best performer for the case. This is supported by references [5,6,7], which demonstrate satisfactory results obtained by using this model for turbomachinery. Moreover, pressure-based solver type, coupled solution algorithm, and 30 iterations per time step were used. The boundary conditions included a velocity inlet of 8 m/s in the x-axis direction, a pressure outlet of 0 Pa (gauge), symmetry on the side edges, a sliding interface between the SZ and RZ, and a wall on the blades with a no-slip condition and stationary in relation to the RZ.

3 Results and Discussion

The authors of [3] suggest using a convergence criterion of 0.1% deviation in Cp value over two subsequent rotor revolutions. In this study, the criterion was met prematurely and produced unrealistic Cp values, leading to a revision requiring at least three consecutive revolutions with four decimal place precision. Table 1 displays Cp results for five operating points along with relative percentage error compared to [3], number of revolutions required for convergence, and simulation time.

Comparing with CFD data from reference [3], errors were below 10%, considered sufficient for methodology validation. Total simulation time using one reference workstation was estimated at 1600 h, and with a mesh sensitivity study, it would be at least three times longer.

Concerning spatial discretization, it's worth mentioning that y+ results, not included here for conciseness, indicated reliability of the k-ω SST turbulence model. The GRV number showed similar magnitudes and behaviors throughout a complete rotor revolution. Figure 3 displays a variation between 0.022 and 0.032 in maximum values.

Comparing Fig. 3 with Table 1, it can be observed that at TSR of 1.1 (operating point with highest prediction errors), the GRV behavior is more chaotic and has a larger amplitude between minimum and maximum values. Conversely, at other operating points, the amplitude is smaller, and behavior is more uniform.

Table 2 shows that Co* is below the recommended upper limit of 10 in temporal discretization, indicating potential to increase the time-step, resulting in decreased simulation convergence time. Like GRV, Co* does not significantly vary after a few rotor revolutions, allowing evaluation of the time-step without waiting for convergence.

4 Conclusions

The CFD methodology applied to a small Darrieus H TEEV in reference [3] was successfully replicated in this study. Results in Table 1 showed small errors compared to reference methodology, demonstrating its validity. However, modifications and adaptations were necessary, such as the adaptation of the simulation convergence criterion. It is recommended to consider the simulation converged after Cp does not vary for three consecutive rotor revolutions at four decimal place precision.

The high computational demands of the simulation (1600 h for five operating points) emphasize the significant resources required for predicting aerodynamic performance of H-Darrieus VAWT. Monitoring GRV from the start of the simulation allows for early assessment of spatial discretization adequacy, avoiding the need to wait for Cp convergence and simplifying methodologies requiring multiple simulations, such as optimization, by eliminating mesh sensitivity studies. Results in Fig. 3 suggest that GRV values up to 0.022 indicate adequate mesh and reliable Cp results for the three-bladed H-Darrieus VAWT.

Finally, after establishing an appropriate GRV number, the time-step should be adjusted to result in Co* < 10. Like GRV, Co* stabilizes in the early revolutions, making it useful for determining the time-step. Setting limits on GRV and Co* can be beneficial in cases of limited computational resources or tasks requiring many simulations.

References

Yepes, D., et al.: Biomass gasification in downdraft dual stage reactor by experimental analysis and simulation with CFD tools. In: European Biomass Conference and Exhibition Proceedings, vol. 25, pp. 808–816 (2017). ISSN 22825819

Sarmiento, A., Yepes, D., Chejne, F., Lora, E.: Gasification of agro-industrial wastes for electricity cogeneration. In: ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, vol. 3, paper No: GT2015–43410, V003T03A008 (2015). https://doi.org/10.1115/GT2015-43410

Balduzzi, F., Bianchini, A., Maleci, R., Ferrara, G., Ferrari, L.: Critical issues in the CFD simulation of Darrieus wind turbines. Renew. Energy 85, 419–435 (2016). https://doi.org/10.1016/J.RENENE.2015.06.048

Balduzzi, F., Bianchini, A., Ferrara, G., Ferrari, L.: Dimensionless numbers for the assessment of mesh and timestep requirements in CFD simulations of Darrieus wind turbines. Energy 97, 246–261 (2016). https://doi.org/10.1016/J.ENERGY.2015.12.111

Sarmiento, A.L.E., Camacho, R.G.R., de Oliveira, W., Velásquez, E.I.G., Murthi, M., Diaz Gautier, N.J.: Design and off-design performance improvement of a radial-inflow turbine for ORC applications using metamodels and genetic algorithm optimization. Appl. Thermal Eng. 183, 116197 (2021). https://doi.org/10.1016/j.applthermaleng.2020.116197

Espinosa Sarmiento, A.L., Ramirez Camacho, R.G., de Oliveira, W.: Performance analysis of radial-inflow turbine of ORC: new combined approach of preliminary design and 3D CFD study. J. Mech. Sci. Technol. 34(6), 2403–2422 (2020). https://doi.org/10.1007/s12206-020-0517-5

Sarmiento, A.L.E., de Oliveira, W., Camacho, R.G.R.: Influence of the vortex design method in the performance characteristics of reversible axial rotors. J. Braz. Soc. Mech. Sci. Eng. 39(5), 1575–1588 (2016). https://doi.org/10.1007/s40430-016-0680-x

Acknowledgments

Thanks to the Federal University of Itajubá (UNIFEI), the PPGEEN (Postgraduate Program in Energy Engineering) and the Research Support Foundation of the State of Minas Gerais (FAPEMIG) (processes APQ-00653-22 and APQ-01865-18 referring to the Projects, respectively: “Numerical and Experimental Analysis of Wind Microgenerators for Applications in Remote Regions in Brazil” – call 001/2022, registration at DPI UNIFEI No: PVDI297-2022 – and “Multi-objective optimization algorithms of computationally expensive functions with application in fluid dynamic design of flow machines and in robust optimization of mechanical designs”) for funding this research.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Junior, C.A.B.S., Sarmiento, A.L.E., Balduzzi, F. (2023). Dimensionless Coefficients for Validation and Evaluation of a CFD Methodology Applied to a H-Darrieus Vertical Axis Wind Turbine. In: Vizán Idoipe, A., García Prada, J.C. (eds) Proceedings of the XV Ibero-American Congress of Mechanical Engineering. IACME 2022. Springer, Cham. https://doi.org/10.1007/978-3-031-38563-6_5

Download citation

DOI: https://doi.org/10.1007/978-3-031-38563-6_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-38562-9

Online ISBN: 978-3-031-38563-6

eBook Packages: EngineeringEngineering (R0)