Abstract

This work describes a machine vision system workflow to automatically estimate the broaching tool wear. The proposed system offers the possibility to evaluate the evolution of wear under different machining conditions and to decide when a tool should be replaced, guaranteeing the quality of the machined part and avoiding catastrophic tool breakage. In addition, the paper discusses the advantages of the proposed method over the traditional and widely used ISO 3685:1993 based methods, which are highly influenced by the operator. The proposed method uses a novel wear area segmentation technique based on Machine Learning artificial intelligence, generating highly reproducible values, saving technicians labor-intensive tasks, and obtaining values with high accuracy. The results show a strong relationship between the values obtained by the proposed automatic method and the experimental ones, with errors below 0.17% and 2.88% corresponding to the MSE and MAE respectively.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The new idea of Industry 4.0 aims to implement all technological advances in various fields to boost production capabilities, streamline production processes, and make it easier for operators to do their tasks. One of the existing technologies that represents great advantages in the automation of production processes is artificial vision based on artificial intelligence [1].

To achieve the highest quality material cutting during the machining process, tool integrity is essential [2]. Therefore, new manufacturing models require intelligent machining to cope with dynamics, process variations and complexity. In this field, studies related to machining tool wear are necessary to achieve high quality parts. Various recent studies have attempted to monitor the machining process by considering different information such as torque [3], vibration signals [1], acoustic signals [4] and process images [2] to estimate tool wear. However, some studies [1, 2] point out that there is still a lot of work to be done as estimating tool wear is a challenging task, frequently subjective and even more complex when the tool dimensions are in the order of micrometers, as is the case of broaching process. Broaching is a machining process used in the manufacture of complex shapes, both internal and external, required by many industrial sectors such as aeronautics, automotive and marine [3]. A common application of the broaching process is the manufacture of the aero-engine turbine discs fir trees, where both the level of surface and dimensional integrity and the cost of manufacture are critical. Therefore, the interest and requirement for reliable control of tool integrity is of great importance in the broaching process [2, 5, 6].

Direct measurement of flank wear in accordance with ISO 3685:1993 is a frequently used technique for evaluating the broaching tool wear [5]. Nevertheless, this method is laborious and subjective, as it depends on the experience of the operator performing the measurements. However, Machine Learning ML is the basis of many recent advances in artificial intelligence that have been developed in terms of improving evaluations of cutting tool wear. Machine learning is a subfield of artificial intelligence that allows machines to learn, improve and perform a specific task using process data. Thus, the main disadvantages of manual wear measurements can be overcome by ML techniques, which generate highly reproducible values, save technicians labor-intensive tasks and can obtain values with high accuracy. ML algorithms can be divided into three categories depending on the learning system and the type of input data (supervised learning, unsupervised learning, reinforcement learning). These algorithms attempt to perform two main tasks: clustering, in which data is separated into specific classes, and regression, looking for a trend within the data. The various methods used to achieve the different objectives will determine the type of algorithm used, for example Support Vector Machines SVM, Random Forest RF, k-nearest neighbors, etc. [1].

In this work, a machine vision system workflow to automatically estimate the broaching tool wear is proposed. The proposed method is established on in-process images of the tool and is based on the classification of pixels corresponding to the tool wear class. This classification is performed by supervised learning using one of the best performing algorithms in the field of digital image processing, Random Forest RF [1]. In the framework of this study, additional tests are carried out comparing the traditional measurement results using ISO 3685:1993 with the prediction results obtained by the RF algorithm.

2 Methodology

This section describes the broaching tests carried out, as well as the wear assessment by the traditional and the proposed ML-based machine vision method.

2.1 Broaching Test

Figure 1 shows the set-up of the method. The machined part was an Inconel 718 turbine disc of Ø500 mm diameter and a thickness of 34 mm. The experimental set-up was carried out on an EKIN vertical broaching machine working, Fmax = 70kN with an uncoated 18-tooth Tungsten Carbide (Co10%) tool of grade S10. The images of the tool were obtained in process every 5 broaching cycles with a telecentric lens camera, LED light source, and integrated commercial imaging software. The resolution of all images was 1280x1024 and recorded with (.jpg) extension.

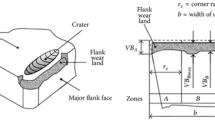

2.2 Flank Wear Measurement by ISO 3685 Method

Firstly, once all the images of each flank were captured at different slots, the flank wear was measured in the traditional way according to the ISO 3685:1993 ISO8688-1 and 2 standards [6, 7]. Based on several studies [3, 5, 8], when machining with flat-faced tools, flank wear (VB) or crater wear (KT) are considered as main tool wear measurement parameters. Therefore, the procedure described in ISO 3685 (Fig. 1b) is applicable to the broaching process for the measurement of wear on its cutting tool.

2.3 Flank Wear Prediction by Machine Vision

The process of predicting flank wear by machine vision is shown in Fig. 2. First, after preliminary tests using a calibrated standard, the angle of image acquisition that was most representative of the actual magnitude of flank wear was determined. Then, a software tool was developed to delimit the Region of Interest (ROI), in which the tool wear occurs, thus avoiding undesiring effects that may lead to errors in prediction. This automated approach, which is based on morphological procedures, was successful with all of the test images (Fig. 2a). As the broaching tool comprises cutting-edge, 18 images were obtained in each slot. The labelling was performed on 5% of the pixels for only three out of the eighteen images in each pass. The pixels where classified into 5 classes (for a multi-class classification), including wear, background, tool, drill, and chip. Thereafter, the attributes of the model were obtained. In this study, more than 150 digital filters were assigned as attributes (Fig. 2a). After the attributes were obtained, the RF classification algorithm implemented in the Scikit-learn python library, version 1.0.2 was used for multi-classification [9]. The number of trees used in each prediction was 100. Finally, once the RF classifier was trained, the model can be used to predict tool wear in new images.

2.4 Predictive Performance

Through the comparison of a set of experimental data with the prediction results, it is possible to estimate the performances of various types of AI algorithms, such as shallow neural networks (SNN), deep neural networks (DNN), and Random-Forest (RF) algorithms. Mean Absolute Error (MAE) and Mean Squared Error (MSE) are two commonly used comparative metrics. Thus, in the present work, both MAE and MSE metrics were used to evaluate the accuracy of the proposed model. Equations (1) and (2) indicate the determination of the above metrics:

where, yexp represents the experimental values obtained by the traditional method based on ISO 3685:1993 and ypred the values predicted by the model.

3 Results

Figure 3 shows the results of flank wear measurements using the traditional method (Fig. 3a) and the proposed (Fig. 3b). Progressive wear is observed as the number of machined grooves increases. The result is consistent with the nature of the process, as each edge is theoretically designed to cut through more and more matter. However, adhesion may occur at the cutting edge, increasing the cutting cross-section and thus leading to increased flank wear (case of the cutting-edge number 9).

By comparing both methods prediction results, an MSE of 0.17% and MSA of 2.88% were achieved (Fig. 4a). Although noise was present in certain sets of acquired images, the algorithm was able to classify the flank wear accurately (results in line with the ones obtained by the traditional method (Fig. 4b), in much less time and in an automatic way. In addition, it is observed that the flank wear and the wear area obtained by the RF algorithm have a direct relationship which is reflected in the trend of wear progress. Consequently, these two metrics are considered useful for assessing wear growth.

4 Conclusions

In this paper, flank wear on tool edges in broaching operation was evaluated using two methods: a traditional method under ISO 3685:1993 and by means of a Random Forest (RF) machine learning algorithm. The performance of the algorithm was evaluated on images acquired in process. The performance was determined using the MSE and MSA indicators, resulting in 0.17% and 2.88% respectively. It is therefore concluded that the Random Forest algorithm has potential utility for assessing flank wear development.

It is known that labelling improves the accuracy and indicators of the model. This study concludes that with the labelling of 3 mages of the 18 that confirm the broaching tool, a high density of labelling (5% of the pixels of the image), and with 4 different classes is sufficient to obtain repeatable and reliable results of tool wear.

Although not demonstrated in this study, the proposed ML-based method could be transferred to industrial environments and implemented in collaborative robots, increasing the level of automation and monitoring of tool wear in production processes.

In the future, a comparison of the performance of the Random Forest algorithm with other ML-based image processing algorithms will be carried out. Learning will also be extended to other weathering phenomena, such as cratering.

References

Kim, D.-H., et al.: Smart machining process using machine learning: a review and perspective on machining industry. Int. J. Precis. Eng. Manuf.-Green Technol. 5(4), 555–568 (2018). https://doi.org/10.1007/s40684-018-0057-y

Fernández-Robles, L., Sánchez-González, L., Díez-González, J., Castejón-Limas, M., Pérez, H.: Use of image processing to monitor tool wear in micro milling. Neurocomputing 452, 333–340 (2021). https://doi.org/10.1016/J.NEUCOM.2019.12.146

del Olmo, A., et al.: Tool wear monitoring of high-speed broaching process with carbide tools to reduce production errors. Mech. Syst. Signal Process. 172, 109003 (2022). https://doi.org/10.1016/J.YMSSP.2022.109003

Elangovan, M., Devasenapati, S.B., Sakthivel, N.R., Ramachandran, K.I.: Evaluation of expert system for condition monitoring of a single point cutting tool using principal component analysis and decision tree algorithm. Expert Syst. Appl. 38, 4450–4459 (2011). https://doi.org/10.1016/J.ESWA.2010.09.116

ISO - ISO 3685:1993 - Tool-life testing with single-point turning tools. https://www.iso.org/standard/9151.html. Accessed 01 June 2022

ISO - ISO 8688–1:1989 - Tool life testing in milling — Part 1: Face milling. https://www.iso.org/standard/16091.html. Accessed 14 July 2022

ISO - ISO 8688–2:1989 - Tool life testing in milling — Part 2: End milling. https://www.iso.org/standard/16092.html. Accessed 14 July 2022

Tool Life Testing with Single - Point Turning Tools – ASME. https://www.asme.org/codes-standards/find-codes-standards/b94-55m-tool-life-testing-single-point-turning-tools/1985/drm-enabled-pdf. Accessed 01 June 2022

Scikit-learn: Machine Learning in Python. https://jmlr.csail.mit.edu/papers/v12/pedregosa11a.html. Accessed 14 July 2022

Acknowledgments

This research has been funded by the group IT1573–22 of the Basque Government and the grant PID2019-109340RB-I00 funded by MCIN/AEI/ https://doi.org/10.13039/501100011033 and PDC2021-121792-I00, AIMS-Opticed Elkartek project, project (QUOLINK) Ministry of Science and Innovation 2021, and the MICINN project PDC2021–121792-I00. Thanks are due to the Universidad Técnica de Ambato for supporting the research.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Holgado, I., Pérez-Salinas, C., Ortega, N., de Lacalle, L.N.L., del Olmo, A. (2023). An Intelligent Machine Learning Based Method for Tool Wear Estimation in the Vertical Broaching Process. In: Vizán Idoipe, A., García Prada, J.C. (eds) Proceedings of the XV Ibero-American Congress of Mechanical Engineering. IACME 2022. Springer, Cham. https://doi.org/10.1007/978-3-031-38563-6_45

Download citation

DOI: https://doi.org/10.1007/978-3-031-38563-6_45

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-38562-9

Online ISBN: 978-3-031-38563-6

eBook Packages: EngineeringEngineering (R0)