Abstract

The global trend towards stricter vehicle emission standards requires more knowledge about the use of renewable fuels to design strategies to reduce the use of non-renewable fossil fuels and the environmental impacts of road transport vehicles equipped with Diesel engines. In this study, a simple phenomenological model with three combined Wiebe functions is used to describe the main injection heat release rate of an unmodified heavy-duty diesel engine fueled with binary blends of n-butanol (up to 20% by volume) with diesel fuel. Conventional diesel was used as the reference fuel to compare combustion characteristics with the binary blends (DBu5, DBu10 and DBu20). The results show that the apparent heat release rate (\(AHRR\)) calculated from the model is in good agreement (RMSE ≤ 3.80 J/°CA) with the experimental values. The maximum \(AHRR\) values (J/°CA) for the fuel blends DBu5, DBu10, DBu20 and the reference diesel were 220.7, 219.1, 211.8 and 217.7 respectively.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The growing problems of environmental pollution and global warming have been a concern for governments and other social institutions for the past decades. Emissions from the transportation sector are estimated to be one of the main sources of air pollution affecting human health and the environment [1, 2]. In addition, the global trend to adopt stricter vehicle emission standards [3, 4] makes it necessary to consider the possibility of using alternative environmentally friendly fuels to replace fossil diesel [5].

The use of simple combustion models, such as the Wiebe function [6], to analyze or predict the combustion process can accelerate knowledge and help optimize engine performance with alternative fuels. The diesel combustion phenomenon is usually divided into three phases, namely, premixed combustion, diffusion combustion, and late combustion phase [7]. Each of these phases has a different combustion rate, so no single Wiebe function can be applied for the characterization of the entire combustion process [6]. Serrano et al. [8] simulated the premixed, diffusion, and late combustion phases of a turbocharged diesel engine by combining three Wiebe functions. Xu et al. [9] used the triple Wiebe function (to represent the premixed, main, and late combustion phases) and found that the triple Wiebe function was more accurate and preferable in terms of predicting the evolution of the mass fraction burned. A similar observation was made by Awad et al. [10] who experimentally studied the three combustion phases of a diesel engine fueled with diesel and biodiesel.

This study models the experimental data of an unmodified four-cylinder Diesel engine consuming diesel/n-butanol blends using a single zone combustion model along with the modified triple Wiebe equation.

2 Materials and Methods

2.1 Experimental Setup

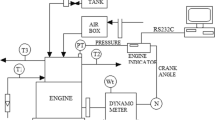

The experimental setup consists of an engine (Table 1), dynamometer control unit, fuel metering unit, eddy current dynamometer, in-cylinder pressure recording unit and data acquisition system.

In-cylinder pressure data acquisition was performed using a combustion analysis system (KiBox) consisting of an AVL GH14D cylinder pressure transducer, a charge amplifier, and a crankshaft angle adapter. Data were collected in KiBox for 100 consecutive cycles with a crankshaft angle resolution of 0.1°CA. The engine was preconditioned for 10 min following the procedure established in regulation 49 [11]. Then, it was run for the prescribed time in mode 11 of the World Harmonized Stationary Cycle at the speed of 1260 rpm and 50% load. All fuels were tested three times to ensure that the results were sufficiently repeatable.

2.2 Fuels

Four fuels were tested. Pure diesel (called Diesel) as reference, and three binary blends: DBu5/10/20; with 5%, 10% and 20% n-butanol added to neat diesel (Table 2).

2.3 Wiebe Function for Combustion Model

The Wiebe function represents the evolution of the fuel burned fraction during combustion phenomena [7, 10, 12]. The triple Wiebe function used in this study is Eq. (1).

where for \(\theta >{\theta }_{i}\); \(sign\left(\theta -{\theta }_{i}\right)=1\), else. \(sign\left(\theta -{\theta }_{i}\right)=-1\); θ_i = crank angle at which ith phase of combustion starts; \(\Delta {\theta }_{i}\) = combustion duration of ith phase of combustion; \({a}_{i}\) = efficiency factor for the ith phase of combustion; \({m}_{i}\) = form factor for the ith phase of combustion; \({\beta }_{i}\) = total burn fraction for the ith phase of combustion.

The model approximation \(AHRR\) compared with experimentally calculated \(AHRR\). Equation (2) was used to predict the gross apparent heat release rate (\({Q}_{ch}\)) [7, 12].

where \({X}_{b}\) (\(\theta \)) is the burn fraction at a particular crank angle (\(\theta \)) predicted using triple Wiebe function, \({m}_{f}\) is the fuel consumption per cycle (g), \(LH{V}_{fuel}\) is the lower heating value of fuel (J/g), \({\eta }_{comb}\) is the combustion efficiency [7].

The modeled heat release rate data were used to predict in-cylinder pressure using Eq. 3 [12] derived from the analysis of the first law of thermodynamics.

\(V\) is the in-cylinder volume, \(\gamma \) is the specific heat ratio, \(p\) is the in-cylinder pressure.

3 Results and Discussion

Figure 1 shows the comparison between experimental and simulated in-cylinder pressure values for diesel fuel. The combustion model was validated using the fitted Wiebe function to estimate the heat release rate, this rate was used to predict the in-cylinder pressure during the combustion process. The accuracy of each format of the triple Wiebe function was evaluated using the root-mean-square error (\(RMSE\)) to compare the predicted heat release rate and in-cylinder pressure to the experimental data. The RMSE values determined are ≤1.2 bar for all fuels. The max. in-cylinder pressure values (bar) for fuel DBu5/10/20 and diesel were 110.2, 111.0, 112.2 and 111.1 respectively. The max.in-cylinder temperatures (°C) were 2265, 2256, 2256 and 2262.

The parameters of the Wiebe triple function obtained by curve fitting of the experimental data on the combustion fraction are given in Table 3. The form factor values in the first stage (\({m}_{1}\)) of combustion are significantly larger than those in the second stage (\({m}_{2}\)) for diesel and binary blends. This is because the initial combustion is slower during the start of combustion, while the initial combustion is faster during the second stage of combustion, which is obvious from the nature of premixed combustion in the IC engine [10]. Moreover, the Wiebe triple function predicted the mass fraction burned (\({X}_{b}\)) with good accuracy (R2 = 0.99).

Figure 2 and 3 show the \({X}_{b}\) and \(AHHR\) profiles for all fuels, respectively. The \(AHRR\) calculated with the model is in good agreement with the experimental \(AHRR\) (\(RMSE\) ≤ 3.80 J/°CA). The low n-butanol contents in the binary mixture do not show considerable variations in the combustion process. It is important to note that the DBu20 blend leads to a slower initial combustion (Table 3) due to the lower CN of n-butanol.

The maximum AHRR value for diesel was 217.7 J/ºCA, which decreased to 211.8 J/ºCA when adding n-butanol (DBu20 fuel blend) due to the lower calorific value of the n-butanol blended fuel [13]. The maximum AHRR values of DBu5 (220.7 J/ºCA) and DBu10 (219.1 J/ºCA) are slightly increased without considerable variations, due to the proper atomization and air/fuel mixing of oxygenated fuels with n-butanol [14].

The combustion starts earlier and has a shorter ignition delay (6.1°CA) for diesel compared to DBu20 (7.1°CA). The addition of n-butanol increases the ignition delay from 6.1°CA to 7.1°CA. This is expected because n-butanol has a lower cetane number than diesel [15]. With the use of DBu5 and DBu10 blends the effect on ignition delay is less evident, with values of 6.1°CA and 6.7°CA, respectively.

Experimental vs. model Burn faction (\({X}_{b}\)) [\(Xb\_exp\) – experimental burn fraction, \(Xb\_tw\) – burn fraction fitted applying triple Wiebe function, \(Xb\_f\) – burn fraction of first phase, \(Xb\_s\) – burn fraction of second phase, \(Xb\_t\) – burn fraction of third phase] for all fuels.

4 Conclusions

The zero-combustion model using Wiebe’s triple combustion fraction predicted the AHRR data with good accuracy for all fuels. The results show that the DBu5 and DBu10 blends did not alter the peak in-cylinder pressure and peak apparent heat release rate (AHRR) values, while slightly decreasing the peak in-cylinder temperature, with no significant changes in ignition delay and combustion duration. The DBu20 blend has no relevant variations in peak in-cylinder pressure and temperature, slightly reduced peak AHRR, also increased ignition delay and reduced combustion duration. The results may be beneficial to promote the use of n-butanol as an alternative renewable fuel in diesel engines to comply with emission control regulations.

References

Jeyaseelan, T., et al.: A comprehensive review on the current trends, challenges and future prospects for sustainable mobility. Renew. Sustain. Energy Rev. 157, 112073 (2022)

EIA. International Energy Outlook 2021 - U.S. Energy Information Administration (EIA) 2021. https://www.eia.gov/outlooks/ieo/. Accessed 9 Oct 2022

Mendoza-Villafuerte, P., et al.: NOx, NH3, N2O and PN real driving emissions from a Euro VI heavy-duty vehicle. Impact of regulatory on-road test conditions on emissions. Sci. Total Environ. 609, 546–55 (2017)

Verger, T., et al.: Biomass-based fuel blends as an alternative for the future heavy-duty transport: a review. Renew. Sustain. Energy Rev. 161, 112391 (2022)

Directive (EU) 2018/2001 of the European Parliament and of the Council of 11/12/2018 on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 328, 82–209 (2018). http://data.europa.eu/eli/dir/2018/2001/oj. Accessed 26 Sept 2022

Ghojel, J.I.: Review of the development and applications of the Wiebe function: a tribute to the contribution of Ivan Wiebe to engine research. Int. J. Eng. Res. 11, 297–312 (2010)

Thakkar, K., et al.: Combustion investigation of ternary blend mixture of biodiesel/n-butanol/diesel: CI engine performance and emission control. Renew. Sustain. Energy Rev. 137, 110468 (2020)

Serrano, J.R., et al.: Methodology for characterisation and simulation of turbocharged diesel engines combustion during transient operation. Part 2: Phenomenological Combustion Simulation. Appl. Therm. Eng. 29, 150–158 (2009)

Xu, S., et al.: A phenomenological combustion analysis of a dual-fuel natural-gas diesel engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 231, 66–83 (2017)

Awad, S., et al.: Single zone combustion modeling of biodiesel from wastes in diesel engine. Fuel 106, 558–568 (2013)

Regulation No 49 UN/ECE—Uniform provisions concerning the measures to be taken against the emission of gaseous and particulate pollutants from compression-ignition engines and positive igniti. Off. J. Eur. Union 171, 1–390 (2013)

Liu, J., Dumitrescu, C.E.: Single and double Wiebe function combustion model for a heavy-duty diesel engine retrofitted to natural-gas spark-ignition. Appl. Energy 248, 95–103 (2019)

Huang, H., et al.: Influence of n-butanol-diesel-PODE3-4 fuels coupled pilot injection strategy on combustion and emission characteristics of diesel engine. Fuel 236, 313–324 (2019)

Emiroğlu, A.O., Şen, M.: Combustion, performance and emission characteristics of various alcohol blends in a single cylinder diesel engine. Fuel 212, 34–40 (2018)

Yusri, I.M., et al.: Evaluation of engine combustion and exhaust emissions characteristics using diesel/butanol blended fuel. Appl. Therm. Eng. 156, 209–219 (2019)

Acknowledgement

This work was conducted within the research project H2020-LCE-2015 Waste2Fuels ‘Sustainable production of next generation biofuels from waste streams’ [N. 654623], funded under the European Union’s research and innovation program Horizon 2020.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Tipanluisa, L., López-Martínez, J., Casanova, J., Fonseca, N. (2023). Three-Stage Combustion Modeling of a Binary Mixture-Fueled CI CRDI Engine. In: Vizán Idoipe, A., García Prada, J.C. (eds) Proceedings of the XV Ibero-American Congress of Mechanical Engineering. IACME 2022. Springer, Cham. https://doi.org/10.1007/978-3-031-38563-6_38

Download citation

DOI: https://doi.org/10.1007/978-3-031-38563-6_38

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-38562-9

Online ISBN: 978-3-031-38563-6

eBook Packages: EngineeringEngineering (R0)