Abstract

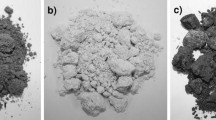

For several decades, the cement industry has been actively seeking alternative raw materials to reduce greenhouse gas emissions and energy consumption. In pursuit of partial replacements for clinker, worldwide research has focused primarily on industrial (fly ash, Si-Mn slag, fired clay-based) and agroforestry (rice husk, sugar cane) waste. The common denominator in all such waste, its pozzolanicity, determines mechanical performance and durability throughout the service life of the cement produced. In this study, two types of industrial waste (construction and demolition waste and biomass waste) were added separately or jointly in different proportions to Portland clinker to ascertain the effect on the rheological, physical and mechanical properties of the resulting binary and ternary eco cements. The use of biomass waste and the joint addition of both kind of wastes were observed to yield cements in which the fresh and hardened properties of the new eco-cement were not significantly lower than in conventional binders and these binders could be apt to use in the manufacture of cement-based material (mortar or concrete) with low-carbon footprint .

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

De Lena, E., Arias, B., Romano, M.C., Abanades, J.C.: Integrated calcium looping system with circulating fluidized bed reactors for low CO2 emission cement plants. Int. J. Greenhouse Gas Control 114 (2022)

Medina, J.M., Saez del Bosque, I.F., Frias, M., Sanchez de Rojas, M.I., Medina, C.: Design and properties of eco-friendly binary mortars containing ash from biomass-fuelled power plants. Cem. Concr. Compos. 104 (2019)

Jidrada, P., Sua-iam, G., Chatveera, B., Makul, N.: Recycling of combined coal-biomass ash from electric power plant waste as a cementitious material: characteristics and improvement. J. Mater. Cycles Waste Manag. 18, 527–540 (2016)

Saez del Bosque, I.F., Medina, J.M., Frias, M., Sanchez de Rojas, M.I., Medina, C.: Use of biomass-fired power plant bottom ash as an addition in new blended cements: effect on the structure of the C-S-H gel formed during hydration. Constr. Build. Mater. 228 (2019)

Cabrera, M., Galvin, A.P., Agrela, F., Dolores Carvajal, M., Ayuso, J.: Characterisation and technical feasibility of using biomass bottom ash for civil infrastructures. Constr. Build. Mater. 58, 234–244 (2014)

Akinyemi, B.A., Dai, C.: Development of banana fibers and wood bottom ash modified cement mortars. Constr. Build. Mater. 241 (2020)

Amiandamhen, S.O., Adamopoulos, S., Adl-Zarrabi, B., Yin, H., Noren, J.: Recycling sawmilling wood chips, biomass combustion residues, and tyre fibres into cement-bonded composites: properties of composites and life cycle analysis. Constr. Build. Mater. 297 (2021)

Rajamma, R., et al.: Biomass fly ash effect on fresh and hardened state properties of cement based materials. Compos. Part B Eng. 77, 1–9 (2015)

Rajamma, R., Ball, R.J., Tarelho, L.A.C., Allen, G.C., Labrincha, J.A., Ferreira, V.M.: Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 172, 1049–1060 (2009)

Farinha, C.B., de Brito, J., Veiga, R.: Influence of forest biomass bottom ashes on the fresh, water and mechanical behaviour of cement-based mortars. Resour. Conserv. Recycl. 149, 750–759 (2019)

Ayobami, A.B.: Performance of wood bottom ash in cement-based applications and comparison with other selected ashes: overview. Resour. Conserv. Recycl. 166 (2021)

Berra, M., Mangialardi, T., Paolini, A.E.: Reuse of woody biomass fly ash in cement-based materials. Constr. Build. Mater. 76, 286–296 (2015)

Garcia, M.D.L., Sousa-Coutinho, J.: Strength and durability of cement with forest waste bottom ash. Constr. Build. Mater. 41, 897–910 (2013)

Ban, C.C., Ramli, M.: The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: an overview. Resour. Conserv. Recycl. 55, 669–685 (2011)

Sklivaniti, V., et al.: Valorisation of woody biomass bottom ash in Portland cement: a characterization and hydration study. J. Environ. Chem. Eng. 5, 205–213 (2017)

Pavlikova, M., et al.: Valorization of wood chips ash as an eco-friendly mineral admixture in mortar mix design. Waste Manage. 80, 89–100 (2018)

Medina, J.M., Sáez del Bosque, I.F., Frías, M., Sánchez de Rojas, M.I., Medina, C.: Characterisation and valorisation of biomass waste as a possible addition in eco-cement design. Mater. Struct. 50(5), 1–13 (2017). https://doi.org/10.1617/s11527-017-1076-9

Jain, P., Gupta, R., Chaudhary, S.: A literature review on the effect of using ceramic waste as supplementary cementitious material in cement composites on workability and compressive strength. Mater. Today Proc. (2022)

He, X., Zheng, Z., Yang, J., Su, Y., Wang, T., Strnadel, B.: Feasibility of incorporating autoclaved aerated concrete waste for cement replacement in sustainable building materials. J. Cleaner Prod. 250 (2020)

Moreno-Juez, J., Vegas, I.J., Frias Rojas, M., Vigil de la Villa, R., Guede-Vazquez, E.: Laboratory-scale study and semi-industrial validation of viability of inorganic CDW fine fractions as SCMs in blended cements. Constr. Build. Mater. 271 (2021)

Wu, H., Liang, C., Wang, C., Ma, Z.: Properties of green mortar blended with waste concrete-brick powder at various components, replacement ratios and particle sizes. Constr. Build. Mater. 342 (2022)

Oliveira, T.C.F., Dezen, B.G.S., Possan, E.: Use of concrete fine fraction waste as a replacement of Portland cement. J. Cleaner Prod. 273 (2020)

de Matos, P.R., et al.: Utilization of ceramic tile demolition waste as supplementary cementitious material: an early-age investigation. J. Build. Eng. 38 (2021)

Frias, M., Vigil de la Villa, R., Martinez-Ramirez, S., Fernandez-Carrasco, L., Villar-Cocina, E., Garcia-Gimenez, R.: Multi-technique characterization of a fine fraction of CDW and assessment of reactivity in a CDW/lime system. Minerals 10 (2020)

Caneda-Martinez, L., Monasterio, M., Moreno-Juez, J., Martinez-Ramirez, S., Garcia, R., Frias, M.: Behaviour and properties of eco-cement pastes elaborated with recycled concrete powder from construction and demolition wastes. Materials 14 (2021)

Fontes, C.M.A., Silva, R.B., Lima, P.R.L.: Characterization and effect of using bottom and fly ashes from co-combustion of cocoa waste as mineral addition in concrete. Waste Biomass Valorization 10, 223–233 (2019)

Tosti, L., van Zomeren, A., Pels, J.R., Comans, R.N.J.: Technical and environmental performance of lower carbon footprint cement mortars containing biomass fly ash as a secondary cementitious material. Resour. Conserv. Recycl. 134, 25–33 (2018)

Villar-Cocina, E., Valencia Morales, E., Santos, S.F., Savastano, Jr., H., Frias, M.: Pozzolanic behavior of bamboo leaf ash: characterization and determination of the kinetic parameters. Cem. Concr. Compos. 33, 68–73 (2011)

European Commission: Report from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the Implementation of EU waste legislation. Brussels, p. 10 (2018)

Agrela, F., Sánchez de Juan, M., Ayuso, J., Geraldes, V.L., Jiménez, J.R.: Limiting properties in the characterisation of mixed recycled aggregates for use in the manufacture of concrete. Constr. Build. Mater. 25, 3950–3955 (2011)

Ma, Z., Shen, J., Wu, H., Zhang, P.: Properties and activation modification of eco-friendly cementitious materials incorporating high-volume hydrated cement powder from construction waste. Constr. Build. Mater. 316 (2022)

Asensio, E., Medina, C., Frias, M., de Rojas, M.I.S.: Characterization of ceramic-based construction and demolition waste: use as Pozzolan in cements. J. Am. Ceram. Soc. 99, 4121–4127 (2016)

Monasterio, M., Caneda-Martínez, L., Vegas, I., Frías, M.: Progress in the influence of recycled construction and demolition mineral-based blends on the physical–mechanical behaviour of ternary cementitious matrices. Constr. Build. Mater. 344, 128169 (2022)

Jittin, V., Rithuparna, R., Bahurudeen, A., Pachiappan, B.: Synergistic use of typical agricultural and industrial by-products for ternary cement: a pathway for locally available resource utilisation. J. Cleaner Prod. 279 (2021)

ASTM International: ASTM C618 - Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete (2019)

European Committee for Standardization: European Standard EN 450-1 - Fly ash for concrete - Part 1: Definition, specifications and conformity criteria (2013)

European Committee for Standardization: European Standard EN 197-1: Cement - Part 1: Composition, specifications and conformity criteria for common cements (2011)

European Committee for Standardization: European Standard EN 196-1: Methods of testing cement - Part 1: Determination of strength (2018)

European Committee for Standardization: European Standard EN 196-3. Methods of testing cement - Part 3: Determination of setting times and soundness (2017)

Elinwa, A., Ejeh, S.: Effects of the incorporation of sawdust waste incineration fly ash in cement pastes and mortars. J. Asian Archit. Build. Eng. 3, 1–7 (2004)

Abdullahi, M.: Characteristics of wood ash/OPC concrete. Leonardo Electron. J. Pract. Technol. 8 (2006)

Pitarch, A.M., et al.: Pozzolanic activity of tiles, bricks and ceramic sanitary-ware in eco-friendly Portland blended cements. J. Cleaner Prod. 279 (2021)

Kim, Y.J., Choi, Y.W.: Utilization of waste concrete powder as a substitution material for cement. Constr. Build. Mater. 30, 500–504 (2012)

Acknowledgements

This study was conducted under grant PID2019-107238RB-C21 funded by MCIN/AEI/10.13039/501100011033, by ‘ERDF A way of making Europe’. Funding was also possible thanks to funding granted by the Consejería de Economía, Ciencia y Agenda Digital de la Junta de Extremadura and by the European Regional Development Fund of the European Union through the reference grants GR 18122 and IB20131. Author Paula Velardo benefitted from pre-doctoral grant FPU17/06093 funded by MCIN/AEI/10.13039/501100011033 and ‘ESF Investing in your future’.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Velardo, P., Barroso, M., Sáez del Bosque, I.F., Sánchez de Rojas, M.I., De Belie, N., Martínez, C.M. (2023). Development of Eco-cement from Recycled Low-Carbon Footprint By-product. In: Jędrzejewska, A., Kanavaris, F., Azenha, M., Benboudjema, F., Schlicke, D. (eds) International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of Cement-based Materials and Concrete Structures. SynerCrete 2023. RILEM Bookseries, vol 44. Springer, Cham. https://doi.org/10.1007/978-3-031-33187-9_12

Download citation

DOI: https://doi.org/10.1007/978-3-031-33187-9_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-33186-2

Online ISBN: 978-3-031-33187-9

eBook Packages: EngineeringEngineering (R0)