Abstract

Proton-exchange membrane (PEM) cells fuel cells are being used as highly efficient and zero-emission power units to produce electricity from a renewable source. The purpose of the current study is to present the design of a simple PEM type fuel cell model that can be used in an educational environment. The study has illustrated possibility of the design through a product design specification (PDS) process. Three different designs were studied and ranked based on design parameters such as cost, environmental safety, size and weight, educational application etc. Then the highest score design was selected. The selected design then improved by utilizing a 3D computer modelling to come up with the final design. The developed design was then manufactured in house and assembled to form a full functional prototype. The model then was tested, and outcome was compared against existing fuel cell models. Test results show that the prototype can produce reasonable amount of electricity. However, the efficiency of the higher heating value and lower heating value of hydrogen was about 15% less compared to the existing fuel cell model. Furthermore, there are some concerns about the controlling combustible and flammable gas which need to be consumed immediately inside the system instead of storing the gas. The project is under development to be safe enough for any educational environment.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

22.1 Introduction

Today increasing the global warming and air pollution due to the combustion of fossil fuels are an environmental issue. On the other hand, the fossil fuels and non-renewable energy sources are limited so the renewable energies and renewable energy sources become more important than before [1]. Fuel cells are one of the great renewable energy systems which can directly convert the chemical energy of Hydrogen into electricity without combustion process. They do not emit greenhouse gases and their only products are water and heat [2]. Between all fuel cell types, proton-exchange membrane (PEM) fuel cells have the highest power density and lowest operating temperature [3]. For a wide range of applications like portable electronic telecommunications, transportation applications and educational purposes.

Electrode has an important role in the PEM fuel cells and improving its performance and durability affects the PEM fuel cell efficiency and performance. In the PEM fuel cells, platinum is used as the catalyst and despite its high price, it is still used due to its high chemical stability and other advantages. There are attempts to use metals like Cobalt as the catalyst in PEM fuel cells which are non-noble metal and cheaper than Platinum [4].

Several research have been done to investigate the effects of various parameters such as water management on the PEM fuel cells performance and durability so far. Goßling et al. studied a 2D and 1D model of a PEM fuel cell stack considering the water management and water balance in the fuel cell [5]. Wang et al. studied the effect of liquid water in porous electrodes and developed a 3-D and two-phase model of the PEM fuel cell [6]. Rahimi-Esbo et al. manufactured a transparent PEM fuel cell according to a numerical design and introduced this transparent PEM fuel cell as the cheapest and simplest method for investigation of water management [7]. Ferreira et al. have studied the effect of gas diffusion layer (GDL) with a microporous layer (MPL) on improving water management and the effect of membrane thickness changes on the operation of PEM fuel cells [8]. Robert et al. studied the effects of chemical and mechanical degradation on the morphology and physicochemical properties of Nafion® membranes. Chemical structure, water transport and sorption using tailor-made devices that can mimic the chemical and mechanical conditions typical of fuel cell operation. Membrane degradation was induced by simultaneously exposing the membrane to a free radical environment and cyclic compression. On the other hand, repetition of the 0.1 Hz compression sequence was implemented to induce mechanical fatigue close to that caused by membrane expansion/contraction during transient fuel cell operation [9].

Kahveci et al. coated the flow channels of the bipolar plates of the PEM fuel cell with different materials and studied water management in each case experimentally. They also found out the PEM fuel cell stack with the hydrophobic Polytetrafluoroethylene (PTFE) coated plates supply the maximum power density and current density compared to others [10]. Smith et al. Introduced a team-based design fuel cell modules which Includes the latest PEMFC science. This module is intended to focus on fuel cells Revitalize the Pinewood Derby R New generation PFSA performance improvements of the new generation of PFSAs over conventional Nafion, Increased efficiency and power density as a function of improved proton conductivity. This educational module also A compromise between conductivity and mechanical durability in the PEMs [11].

There is numerous research in the field of PEM fuel cells experimentally but there are a few research about the PEM fuel cells for using in the educational environments such as schools, colleges and universities for educating the students about renewable energy sources and fuel cells. Therefore, this study has aimed to build a fuel cell that is portable, easy to assemble and disassemble, safe and visible to show the functions are taking place in that. The study has designed and manufactured a fuel cell prototype based on PEM fuel cell technique which is suitable to be used in the educational environment. The model must be safe and have adjustable parameters, such as voltage, have a sturdy base as well as visible for students to observe what is happening in the model.

22.2 Methodology

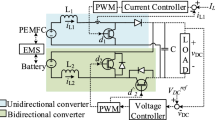

Initial design: The initial design kept simple to make sure it is feasible at student level. The schematic of design illustrated in Fig. 22.1. The design was included with platinum mesh electrodes as a catalyst with a Proton Exchange Membrane as its electrolyte along with distilled water to hydrate the membrane. The electrolyser container consists of two clear acrylic plates with a square cut-out in each to house the electrodes, gas diffusion layer and distilled water with both plates being secured together with bolts at each corner. The membrane will be sandwiched in-between both plates and act as a gasket to prevent gas escaping. The diagram of this fuel cell and the table of its components and the used materials is shown in Fig. 22.2 and Table 22.1.

The initial concept is a reasonable choice for educational purpose because it is portable and safe as the liquid electrolyte is used in that, is distilled water which won’t cause any harm. This concept also clearly shows what is happening inside the fuel cell and where each gas is going. Another key characteristic is that it is secured using bolts and can easily be taken apart to show each component. The concept can also be reversed to be used as an electrolyser too, which can be done by attaching a power source to the electrodes instead of a load. However, a notable disadvantage of this concept is that the materials were used in this concept, may be expensive and cannot be created at home by students.

Final design: The study was considering 20 different parameters of the proposed concepts such as weight, size, environmental safety, cost, educational application and etc. and based on the importance of each parameter. A weighting score of 1 to 5 for each parameter was given and then the parameters rated between 1 and 5 for each feature. The rating of 5 implies that the design is excellent in that characteristic, whereas a rating of 1 show that the design is very poor in that characteristic. The overall score was calculated by multiplying the weight and the rating of that parameter and all the overall scores was added together to give the total score of that initial concept. The higher the total score, the better the design concept. Among few initial concepts, the concept with highest score was candidate for further study and prototyping.

Amendments made on the initial design are displayed in red in Fig. 22.3. The base will be a 200 × 200 × 2 mm sheet of acrylic which will hold the fuel cell and any other parts sturdy (Fig. 22.4).

22.3 Models

Fuel Cell Manufacture

Figure 22.5 shows the different parts which were used in the assembly of the fuel cell. These parts are also listed with its materials and dimensions in Tables 22.2 and 22.3. The electrodes were cut from its original length to 45 × 45 mm to allow it to fit in the prototype and the gas diffusion layer was also cut to fit. We see the assembled fuel cell in Fig. 22.6 that showing the side and front profiles with all parts inside, such as the membrane, electrodes and GDL. Some amendments such as drilling a new hole under the electrode handle, a sealant, a washer and etc. were applied to the prototype.

Figure 22.7 shows the full assembly of the prototype on the base with the gas collecting cylinders. The side with the red-wire is the oxygen side and the side with the black wire is the hydrogen side. The prototype is without gas diffusion layer. The electrode handles had also been cut to fit a spade terminal to make ease of connecting loads, as well as a multi-meter to test different parameters of the prototype.

Testing: We tested both educational fuel cell kit and prototype fuel cell in terms of their efficiency and the hydrogen and oxygen they consume. We tested the prototype fuel cell in two steps. In first step, the hydrogen was inputted to the prototype via the educational kit working as an electrolyser. In second step, the fuel cell was used as an electrolyser to make hydrogen and then was used as a fuel cell to use the hydrogen. The multi-meter showed the output voltage of the prototype as well as the hydrogen and oxygen it consumed in both steps. The efficiencies based on higher heating value and lower heating value was also calculated by Eqs. 22.1 and 22.2, respectively.

During the 2nd attempt at testing the fuel cell, gas tubes were connected from the fuel cell to the gas containing cylinders and a power supply of 2 V at 0.7A were attached to the anode and cathode of the prototype. This resulted in oxygen bubbles being created at the cathode, however after a few minutes, no gas had entered the cylinders and the distilled water had started leaking from the membrane. After this occurrence, the prototype was again taken apart to diagnose any issues (Fig. 22.8).

The above picture shows the membrane once it was removed from the prototype after attempting electrolysis. The membrane had a few spots that looked as if it had been burnt and there was a yellow looking liquid coming off the membrane which could be the perfluoro sulfonic acid (liquid form of the membrane) mixing with the water. The possible reasons for this could be due to the electrodes tearing the membrane during assembly, causing a short and sparking which could explain the burn-looking marks [9]. Another reason could be due to the electrode handle not being platinum, causing an adverse reaction between the titanium and the membrane. From the comparison of the experimental results with the Horizon model [12], it was found that the current prototype is not work well enough and need to improve the design which is in progress in an ongoing project.

22.4 Results and Discussion

Results show that the educational fuel cell kit produces a voltage of 0.918v at the electric current of 0.13A, while it consumes 2.39 ml/min of hydrogen and 1.2 ml/min of oxygen. The efficiencies of the educational fuel cell kit based on higher heating value and lower heating value are 61.9% and 73.2%, respectively. The normal efficiency of a PEM fuel cell is in the 40% to 60% range. So, the educational kit efficiency is higher than the PEM fuel cell efficiency. As we discussed previously, the hydrogen that the prototype fuel cell consumes is supplied either by the educational fuel cell kit as an electrolyser or the prototype itself works as an electrolyser. When the educational kit works as an electrolyser, the prototype fuel cell produces a voltage about 0.778 v and consumes 7.94 ml/min of hydrogen and 3.97 ml/min of oxygen and its higher heating value and lower heating value efficiencies are 52.5% and 62%, respectively which is the middle of the normal efficiency of a PEM fuel cell (40%–60%). Results show that the prototype would not serve as a good educational model as it couldn’t function as an electrolyser to provide hydrogen and oxygen to be used when functioning as a fuel cell. If the prototype is put in an educational environment, the prototype cannot work as an electrolyser and as a fuel cell at the same time. Therefore, in this case, we need a hydrogen and oxygen tank would be required as well as flow meters and flow regulators to prevent damage to the prototype itself. To save the hydrogen and oxygen that the prototype produced use them when the prototype functions as a fuel cell. But having a tank that contains flammable gas like hydrogen is not safe for use in an educational environment.

22.5 Conclusion

In the present investigation, a PEM fuel cell prototype for educational purposes based on the best-evaluated parameters had designed and manufactured. Considering the high score parameters at play in this model are evaluated to efficiency of the model and compared to an existing fuel cell model. Fuel cell kit also can supply Self-consumed hydrogen as an electrolyser.

Test results show that the efficiency of the educational kit is relatively high between 50 and 60% compared to existing fuel cell models based on higher heating value and lower heating value. A prototype can produce hydrogen. However, there is a concern that flammable gas and control of flammable gas require immediate consumption in the system rather than storing the gas.

Considering that the storage of hydrogen fuel for the fuel cell in the tank for educational purposes is risky and does not have enough security, so we can use an electrolyser instead of fuel storage. Therefore, hydrogen produced by the electrolyser can be consumed directly and there is no risk. Thus, this method is safe and can be easily used in educational environments. It should be noted that to reduce the risk as much as possible, the time between production and consumption of hydrogen should be minimized. In the next steps, we will aim to be able to minimize the possible risks of storing hydrogen fuel and the time of its production and consumption with a more optimal design and the use of a suitable electrolyser to produce the required fuel, and a fuel cell with high security which is suitable for use in educational environments.

References

A.A. Ebrahimzadeh, I. Khazaee, A. Fasihfar, Experimental and numerical investigation of obstacle effect on the performance of PEM fuel cell. Int. J. Heat Mass. Transf. 141, 891–904 (2019)

L. Giorgi, F. Leccese, Fuel cells: technologies and applications. Open Fuel Cells J. 6 (2013)

J. Kurtz, C. Ainscough, L. Simpson, Caton M. Hydrogen storage needs for early motive fuel cell markets. National Renewable Energy Lab.(NREL), Golden, CO (United States); 2012.

E.H. Majlan, D. Rohendi, W.R.W. Daud, T. Husaini, M.A. Haque, Electrode for proton exchange membrane fuel cells: a review. Renew Sustain. Energy Rev 89, 117–134 (2018)

S. Gößling, N. Nickig, M. Bahr, 2-D+ 1-D PEM fuel cell model for fuel cell system simulations. Int J Hydrogen Energy 46, 34874–34882 (2021)

Y. Wang, S. Wang, S. Liu, H. Li, K. Zhu, Three-dimensional simulation of a PEM fuel cell with experimentally measured through-plane gas effective diffusivity considering Knudsen diffusion and the liquid water effect in porous electrodes. Electrochim Acta 318, 770–782 (2019)

M. Rahimi-Esbo, A. Ramiar, A.A. Ranjbar, E. Alizadeh, Design, manufacturing, assembling and testing of a transparent PEM fuel cell for investigation of water management and contact resistance at dead-end mode. Int J Hydrogen Energy 42, 11673–11688 (2017)

R.B. Ferreira, D.S. Falcão, V.B. Oliveira, A. Pinto, Experimental study on the membrane electrode assembly of a proton exchange membrane fuel cell: effects of microporous layer, membrane thickness and gas diffusion layer hydrophobic treatment. Electrochim Acta 224, 337–345 (2017)

M. Robert, A. El Kaddouri, J.-C. Perrin, K. Mozet, M. Daoudi, J. Dillet et al., Effects of conjoint mechanical and chemical stress on perfluorosulfonic-acid membranes for fuel cells. J Power Sources 476, 228662 (2020)

E.E. Kahveci, I. Taymaz, Experimental study on performance evaluation of PEM fuel cell by coating bipolar plate with materials having different contact angle. Fuel 253, 1274–1281 (2019)

J.D. Smith, M. Novy, Design of a modern proton-exchange membrane fuel cell module for engineering education, in 2018 IEEE Conference on Technologies Sustainability (IEEE, 2018), pp. 1–6

Horizon Educational, Solar Hydrogen Science Kit, Horizon Fuel Cell Europe. Available from: https://www.horizoneducational.com/solar-hydrogen-science-kit/p1224. Last seen 28 Nov 2021

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Rahman, M.R., Hosseini, F.S., Taleghani, P., Ghassemi, M., Chizari, M. (2023). Design and Prototype an Educational Proton-Exchange Membrane Fuel Cell Model. In: Nixon, J.D., Al-Habaibeh, A., Vukovic, V., Asthana, A. (eds) Energy and Sustainable Futures: Proceedings of the 3rd ICESF, 2022. ICESF 2022. Springer Proceedings in Energy. Springer, Cham. https://doi.org/10.1007/978-3-031-30960-1_22

Download citation

DOI: https://doi.org/10.1007/978-3-031-30960-1_22

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-30959-5

Online ISBN: 978-3-031-30960-1

eBook Packages: EnergyEnergy (R0)