Abstract

With global warming and climate change, the world is experiencing a steady temperature rise. Hence the need for effective and efficient air conditioning, cooling and refrigeration systems is higher than ever. One of the key elements influencing refrigeration system performance is the working fluid. From 2022, new refrigeration systems in the UK must not use refrigeration fluids with global warming potential (GWP) above 150. Widely used R134a, with GWP of 1430, is therefore being banned and the need for suitable replacement fluids, with equivalent or similar thermodynamic performance, is imminent. This paper looks into the potential of low GWP refrigerant fluids, and assesses their suitability to be utilised as replacement for historically used R134a. Operation of a refrigeration cycle based on R134a is comprehensively compared to selected low GWP fluids in different operating conditions. Low GWP fluids (R152a, R1234yf, R1234ze(E), R290, R600a) were carefully selected to include a broad range of thermophysical properties and cover several fluid categories. Compression work requirement, cooling capacity and the overall performance are evaluated in typical operating scenarios. We conclude that both R1234ze(E) and R1234yf are good alternatives. In particular, R1234yf outperformed R134a by requiring less compression work and achieving significantly higher COP based on the same cooling capacity.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Global warming potential

- Coefficient of performance

- Cooling capacity replacement fluids

- Thermodynamic assessment

18.1 Introduction

For decades, and more so since the EU 517/2014 regulations [1], alternatives to working fluids with high Global Warming Potential (GWP) have been sought. Throughout the 20th century hundreds of refrigerant fluids have been synthesised and successfully employed in cooling and air-conditioning systems worldwide. The specific limit of GWP is dependent on the application. Nowadays high GWP refrigerant fluids are being phased out and over the years have investigations focused on identifying suitable replacements. From 2022 all refrigerants fluids with a GWP > 150 will be banned in the UK (there are some exceptions though, yet this is generally the norm). One of the most commonly used refrigerant fluids, R134a, has the GWP of 1430, which is significantly higher than currently acceptable threshold (an ideal refrigerant fluid would have a GWP ≈ 0). Hence, it is imperative to identify replacement refrigerant fluids which would yield similar, if not better, performance.

Zilio et al. [2] investigated the possibility of using R1234yf within an automotive air conditioning system designed for R134a. compared to R134a, a cycle based on R1234yf had lower cooling capacity and the coefficient of performance (COP). However, it was suggested that with some modifications to the cycle set up, R1234yf could reach higher COP at the same cooling capacity as R134a. Navarro-Esbri et al. [3] also concluded that cooling capacity of R1234yf was lower than that of R134a across the operational range examined. In addition to R1234yf, Sánchez et al. [4] considered other refrigerant fluids: R1234ze(E), R600a, R290, and R152a. R1234yf, as well as R1234ze(E) and R600a, showed a notable decrease in cooling capacity. In contract, cooling capacity and COP with R290 increased, albeit significant increase in compressor power requirement. R152a had lower cooling capacity and power required; as a consequence, COP increased.

In the last decade there have been many other studies looking into suitability of these and other refrigerant fluids as suitable replacements in heat pumps and associated systems. In this paper we build upon the existing literature by examining the performance of refrigeration cycles utilising R600a, R152a, R1234yf, R1234ze(E) and R290. Comparison to R134a done on the basis of assessing compression work requirement for the equivalent cooling capacity of the refrigeration cycle.

18.2 Methodology

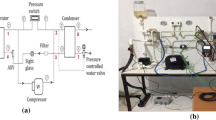

Refrigeration cycle was thermodynamically modelled as a steady-state system. Kinetic and potential energy losses, and heat transfer to the environment were neglected. Pressure drops in all cycle elements were ignored, with pressure changes occurring only during compression and expansion processes. Schematic of a simple refrigeration system is given in Fig. 18.1. Main processes can be outlined as: adiabatic compression, isobaric cooling in the condenser, expansion in the throttle, and isobaric heating in the evaporator. Evaporator pressure was kept constant as saturation pressure at 273 K in all cases. Compression inlet state, point 1, was slightly superheated refrigerant, 5 K above the saturation. Compression ratio (p2/p1) was varied in 2–8 range, with fixed compressor efficiency at 70%. Saturated liquid state at the condenser outlet (point 3) was assumed. The expander operates isenthalpically (h4 = h3). Fluid properties were retrieved from RefPROP. Safety classification and GWP of fluids considered in this study are given in Table 18.1. Heat and work exchanges were calculated as enthalpy gradients between relevant points of the cycle, as outlined below:

with the coefficient of performance:

18.3 Results and Discussion

In order to compare the performance of potential replacement refrigerant fluids to R134a, thermodynamic cycle across a range of compression ratios was modelled. Pressure ratios across the compressor stage considered in this study (p2/p1 = 2–8) are typical for a standard refrigeration cycle. One of the main advantages of R134a is a relatively low compression work. Hence a suitable replacement fluid would have similar (ideally lower) compression work requirement. Evaluated compressor work requirement for replacement fluids considered in shown in Fig. 18.2.

All working fluids studied showed gradual increase in compression work requirement with increasing pressure ratio. R1234yf and R1234ze(E) required slightly less compression work than R134a. R290 has a significantly higher work requirement through the compressor, more than double compared to R134a across all compression ratios, which is in line with [3, 4]. R152a and R600a also required notably higher compression work.

Cooling capacity is a key measure of refrigeration system performance; an effective working fluid would therefore have the ability to remove a substantial amount of heat from refrigerated space. Evaluated cooling capacity for R134a replacement fluids is shown in Fig. 18.3. In agreement with previous findings [2, 3], R1234yf showed consistently lower value for cooling capacity compared to R134a, while that of R1234ze(E) was similar to R134a. However, cooling capacity of R152a and R600a were significantly higher, albeit decreasing more rapidly with increasing compression ratio. Interestingly, R290 showed almost linear trend of cooling capacity decrease with increasing pressure ratio, significantly higher than R134a at low compression ratios, and nearly the same at higher compression ratios.

In terms of COP (Fig. 18.4), performance of R1234ze(E) and R600a was virtually the same as that of R134a. R152a also had practically the same COP at lower compression ratios, and slightly higher COP at higher pressure ratios. Performance of R1234yf was poorer than that of R134a and R290 performed worse in terms of COP, which is contrary to the findings in [4]. Whilst COP and cooling capacity vary across R290, R152a and R600a, these fluids require higher compression work than R134a. Hereafter further analysis is based on R1234yf and R1234ze(E) only.

In Fig. 18.5, we compared cycle performance and cooling capacity in a scenario where compression work was fixed at 20 kJ/kg. Both R1234yf and R1234ze(E) had diminished performance compared to R134a, −24.95% and −9.91%, respectively. In an alternative scenario when cooling capacity was fixed at 125 kJ/kg, R1234yf had the lowest compression work—53% less work then R134a. R1234yf also achieved the highest COP of 6.45 (114.77% higher compared to R134a) followed by R1234ze(E) with a value of 3.81 (26.91% higher). These two scenarios demonstrate that R1234yf and R1234ze(E) both outperform R134a at low cooling capacity loads. Alternatively, when compression work is low R134a achieves better performance. Hence, selection of suitable replacement refrigeration fluid should be based on carefully defined design criteria. In this study thermodynamic similarity was the basis of comparison. Future work may include consideration of broader set of properties as well as various losses in the system.

18.4 Conclusion

Compared to R134a, R290, R600a and R152a had higher cooling capacities, although the compression work was notably higher as well. Overall, these refrigerant fluids could act as replacements for R134a. Equally so, both R1234ze(E) and R1234yf are deemed to be good alternatives. In particular, R1234yf outperformed R134a by requiring less compression work and achieving significantly higher COP based on the same cooling capacity. However, performance of R1234yf and R1234ze(E) was not equivalently good based on the same compression work comparison.

Abbreviations

- h :

-

Specific enthalpy [kJ/kg]

- w :

-

Specific work [kJ/kg]

- q :

-

Specific heat energy [kJ/kg]

- 1–4:

-

Point reference number within the refrigeration cycle

- comp :

-

Compressor

- e :

-

Evaporator

References

Regulation (EU) No 517/2014, Regulation (EU) No 517/2014 of the European Parliament and the Council of 16 April 2014 on fluorinated greenhouse gases and repealing Regulation (EC) No 842/2006. Official J. Eur. Union 57 (2014)

C. Zilio, J. Brown, G. Schiochet, A. Cavallini, The refrigerant R1234yf in air conditioning systems. Energy 36(10), 6110–6120 (2011)

J. Navarro-Esbrí, J. Mendoza-Miranda, A. Mota-Babiloni, A. Barragán-Cervera, J. Belman-Flores, Experimental analysis of R1234yf as a drop-in replacement for R134a in a vapor compression system. Int. J. Refrig. 36(3), 870–880 (2013)

D. Sánchez, R. Cabello, R. Llopis, I. Arauzo, J. Catalán-Gil, E. Torrella, Energy performance evaluation of R1234yf, R1234ze(E), R600a, R290 and R152a as low-GWP R134a alternatives. Int. J. Refrig. 74, 269–282 (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Radulovic, J., Bull, J., Buick, J.M. (2023). Investigation of Working Fluid Performance in a Refrigeration Cycle. In: Nixon, J.D., Al-Habaibeh, A., Vukovic, V., Asthana, A. (eds) Energy and Sustainable Futures: Proceedings of the 3rd ICESF, 2022. ICESF 2022. Springer Proceedings in Energy. Springer, Cham. https://doi.org/10.1007/978-3-031-30960-1_18

Download citation

DOI: https://doi.org/10.1007/978-3-031-30960-1_18

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-30959-5

Online ISBN: 978-3-031-30960-1

eBook Packages: EnergyEnergy (R0)