Abstract

In today’s global business context, data has played a critical role in ensuring accurate and appropriate decision making in manufacturing organisations. Despite the huge pool of information (i.e. data) generated by consumers, repair or maintenance shops, manufacturing job shop, scientific society on various products, which could be deployed by manufacturers in eliciting vital information towards achieving sustainable product design and development, only few manufacturers are making use of this data to generate wisdom required for sustainable manufacturing. This act is caused by lack of appropriate systems capable of integrating the available data and make wise inferences that will result in a competitive advantage of a specific organisation over its competitors. In light of this, the aim of this study is to establish a suitable data analytic platform that could be used to sort, classify and integrate data required to generate wisdom vital for sustainable manufacturing. In order to achieve this, Analytical Hierarchy Process (AHP) was deployed to appraise various alternative data analytical platforms such as Python, Apache Spark, Qlik View, Power BI, Tableau, KNIME, Excel, Talend, Rapid Miner and Statistical Analysis System (SAS) using various criteria such as Data Format, Availability, Interface, Programming Intensity, Data Science Knowledge Intensity and Capabilities. The result of this decision analysis and selection exercise, revealed that KNIME data analytic platform, with the most important decision criterion; data science knowledge intensity, and a cumulative assessment score of 80.80 is the appropriate data analytic platform that manufacturers should use to generate a knowledge advisor vital for sustainable manufacturing and product development.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Manufacturing systems have gone through abrupt changes given the dynamic nature of the environment in which they operate. Customer and system user demands, technological advancements, environmental demands, competition, globalisation and the ability to de-globalise are some of the factors driving this fast change (Gola and Świć 2012). Yao et al. (2019), stated that personalisation and innovation are today’s major metrics to evaluate manufacturing systems and has become the key transformation driver of the 21st century. The ability to have the voice of all stakeholders throughout the process of innovation, product development and manufacturing is one key competitive advantage an organisation can have in today’s business environment. Currently existing manufacturing systems have limitations in fully meeting this demand through optimal integration of all stakeholder voices in their service or product offering (Yao et al. 2015). Abramovici (2007) stated that only one out of seven products ideas succeed in the market. This high failure is caused mainly due to lack of customer orientation.

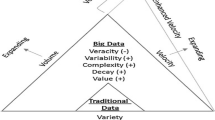

With the social media platforms, there is a room to obtain nearly real-time sentiments from the people within the communities (i.e. the customers) on the products they use. Furthermore, with the advent of Industry 4.0 (Xiong et al. 2017), there is opportunity to deploy embedded sensors to source real-time information on the product health status as well deploy the use of designed database system to elicit information about the product repair records which constitute another stream of product data. Therefore, opportunity exist to integrate these various stream of data, and conduct adequate data analytics on them, towards unveiling wise design idea decisions that would ensure sustainable product design and development.

Wisdom manufacturing can be achieved via the use of Cyber Physical Social System (Yin et al. 2020). According to (Zeng et al. 2016), Cyber Physical Social System (CPSS) are complex systems that satisfy the limitations of the Cyber Physical Systems (CPS) and Cyber Social System (CSS) in order to meet people’s social interactions demands and react to the physical world. CPSSs have been deployed for various applications such as military command and control operations (Liu et al. 2011), smart transport systems (Xiong et al. 2015), smart home (Smirnov et al. 2015), smart medical services (Sheth et al. 2013) and smart cities (Costanzo et al. 2016).

The realisation of WM is the state-of-art manufacturing system that has both the ability to incorporate the social interaction in the process of manufacturing and the product life cycle as well as physical data collected from the product and/or the immediate and broader production environment. Hence, mining relevant data from operators’ social interactions, millions of consumer social media posts, product, equipment and experts publications is a cumbersome task that can only be accomplished through the use of suitable and well-designed algorithms (Abrahams et al. 2012). Social data such as customers, experts, enterprises and other stakeholder’s interaction in the various social media platform, can be collected using social sensors (Ding and Jiang 2016). Physical data such as the health status of a product (Bogue 2014), human-related information (Taraldsen et al. 2012) as well as surrounding environment status such as weather condition (Hernández-del-Olmo et al. 2019) can be gathered by use of physical sensors.

Natural text analytics extracted from the data collected from various streams of data is pivotal for the implementation of the CPSS concept. Abrahams et al. (2013), discussed text mining tools for categorizing and obtaining product intelligence from user-generated contents in social media. Various data analytic platforms such as Microsoft Excel (Neyeloff et al. 2012), R and Phython (Louridas and Ebert 2013), Tableau and Power BI (Negrut 2014) and Konstanz Information Miner (KNIME) platform (Minanovic et al. 2014) have been deployed in the literature for natural text analytics. However, selection of an appropriate data analytic platform based on the strength and weaknesses of these platforms towards ensuring accurate and sound natural text analytics is a salient issue that need to be discussed. In light of this, this study intend to investigate and ascertain a suitable data analytic platform that could be used to integrate various streams of data towards extracting suitable decisions that will promote wisdom manufacturing in various organisations. The structure of the paper are as follows. The second section present the methodology used in this study. The third section present and discuss the results obtained from this study while the last section draw conclusion based on the results obtained from the study and thereafter unveil the future research work.

2 Methodology

Two decision techniques, namely, the Analytical Hierarchy Process (AHP) and the Weighted Decision Matrix (WDM) were used to ascertain the suitable data analytic platform that could be used to develop a wisdom manufacturing system. The ten (10) data analytic platform alternatives considered in this study for developing wisdom manufacturing system are Apache Spark (DAP I), KNIME (DAP J), Power BI (DAP K), Python (DAP L), Qlik View (DAP M), Tableau (DAP N), Microsoft Excel (DAP O), Talend (DAP P), Rapid Miner (DAP Q), and Statistical Analysis System (DAP R). The various criteria used to evaluate the capability of the aforementioned data analytic platforms for developing wisdom manufacturing are discussed as follows:

-

1)

Data Science Knowledge Intensity (DSKI): This criterion served to classify the data science knowledge required for the user to work with the tool. The classification ranged from low to high. Given that current tools are being developed so that it is simpler for an average data scientist to use, the lower the expertise knowledge required to use a machine learning tool, the more the tool is desirable by users.

-

2)

Programming Intensity (PI): This criterion was used to classify the level of programming skills required to use the software. The classification followed a similar approach as that of DSKI level described above. The less programming expertise required, the more desirable is the tool.

-

3)

Interface (I): This criterion describes the type of interface used in operating the tool. The desired tool should have a much user friendly interface, so that it is easy to use.

-

4)

Capabilities (C): this criterion describes major functions provided by the tool concerning data analysis, visualization and machine learning as well as capabilities to integrate with other platforms. The more the capabilities offered by the specific tool, the more desirable the tool is for the study.

-

5)

Data Format (DF): this criterion describes the data types which are supported by the tool to conduct the analysis or machine learning operation. Given that there is a need to conduct the analysis on csv, excel, pdf and data in any other format, the more formats the tool can accommodate the better for the user of the tool.

-

6)

Availability (A): not all analytic tools are easily available; they range from free of charge to high cost licences. Some of the tools have limited versions available for free and the capabilities increase based on the licence acquired. For the purpose of this study, despite all the above criteria, cost of the tool acquisition was highly considered. Freely accessible versions were highly desirable if not compromising the required capabilities needed to conduct the big data analytic exercise.

In the context of this study, the Analytical Hierarchy Process (AHP) was deployed to ascertain the priority weight score of each criterion considered in this study while the WDM was used to ascertain the performance of each alternative data analytic platform considered in this study using the priority weight score of each criterion considered in this study and the rating score of each alternative data analytic platform under each criterion. The procedures used to carry out the AHP and WDM decision analysis are highlighted in the subsequent sections.

2.1 Analytical Hierarchy Process

The pairwise comparison of each criterion against one another was conducted by the authors using the fundamental scale of pairwise comparison and random consistency analysis formulated by Saaty (2008). After this criteria comparative analysis, the most important criterion to satisfy the design requirements of the suitable data analytic platform for wisdom manufacturing system is the criterion with the highest priority weight score while the criterion with the lowest priority weight score is the least important criterion.

2.2 Weighted Decision Matrix

The rating score for each data analytic platform that could be used for wisdom manufacturing system was rated using a three level scale. The three level scale for criterion; DF are tagged as less than or equal to 5, 6 to 10 and 11 or more. The three level scale for criteria; A and I are tagged as Easy, Moderate and Difficult/Complex while the three level scales for criteria; PE, DSE and C are tagged as Low, Moderate and High. The level scales for criteria; DF and C are awarded a grade score of 10, 50 and 100 respectively. The level scales for criteria; A, I, PE and DSE are awarded a grade score within a range of 100, 50, and 10 respectively. If \(PW_{a}\), \(PW_{b}\), \(PW_{c}\), \(PW_{d}\), \(PW_{e}\) and \(PW_{f}\) represent the priority weight score of each criterion obtained from the AHP analysis, and \(R_{a}\), \(R_{b}\), \(R_{c}\), \(R_{d}\), \(R_{e}\) and \(R_{f}\) represent the grade score for each of the criterion used to appraise each data analytic platform, then the cumulative performance grade score for each data analytic platform that could be used for a wisdom manufacturing system is calculated using Eq. (1).

where \(PGS_{n}\) represent the performance grade score for each alternative data analytic platform \(n\) considered in this study, and \(n\) = 1, 2, 3, 4, 5, 6, 7, 8, 9, 10.

Therefore, the data analytic platform with highest cumulative performance grade score is the suitable data analytic platform that could be used for a wisdom manufacturing system.

3 Results and Discussion

3.1 Results of Analytical Hierarchy Process Assessment

The pairwise comparison matrix (\(C\)) of the assessed criteria is presented in Eq. 2.

The normalised comparison matrix, \(N\), obtained by dividing each element in each column of Eq. 2 by each column summation value is depicted in Eq. 3.

After obtaining the normalized values, the criteria weight (\(CW\)) was calculated by obtaining the average value of each row of equation to represent the weight of the respective row criteria. The resultant matrix of the computation is presented in Eq. 4.

Based on the criteria weight matrix presented in Eq. (4), it could be inferred that the weight scores for each criterion are 0.259, 0.112, 0.073, 0.057, 0.327 and 0.172 respectively. In light of this, the criterion; “data science knowledge intensity” is the most important criterion, since it has the highest pairwise criterion weight score.

The result of the Consistency Ratio (CR) computed to confirm the authenticity of the pairwise criterion assessment exercise done in this study was valued at 0.076. Since this result is less than 0.1 as asserted in study of Saaty (2008), therefore, it can be concluded that the pairwise comparison analysis carried out were consistent and not biased.

3.2 Results of Weighted Decision Matrix Assessment

The result of the WDM assessment tailored towards ascertaining a suitable data analytic platform for wisdom manufacturing system using the priority weight scores of the decision criteria obtained from the AHP analysis is depicted in Tables 1 and 2.

Based on Tables 1 and 2, it could be deduced that the cumulative assessment scores of the data analytic platform alternatives I, J, K, L, M, N, O, P, Q and R are 53.65, 80.80, 49.17, 58.87, 66.60, 50.02, 45.24, 53.65, 53.65 and 46.09 respectively. In light of this, Data Analytic Platform J (i.e. KNIME) is the most suitable data analytic platform for WMS since it has the highest cumulative assessment score. This platform combines an easy to use flow interface and different scripting capabilities for personalised algorithms; it supports a variety of files formats and is able to perform all required operations in the WMS framework with minimum programming requirements. Furthermore, it is an open source platform.

4 Conclusion

Wisdom Manufacturing is a futuristic user-centred and data driven manufacturing paradigm which encompasses the inclusion of all product stakeholders throughout the product lifecycle to derive wisdom for product manufacturing and improvement. In light of this, ten (10) data analytic platform alternatives that could be used to achieve Wisdom Manufacturing were evaluated using AHP and WDM decision techniques, in order to ascertain the suitable platform. The criterion, DSE with a priority weight of 32.7%, amidst other criteria such as DF, A, I, PE and C, was considered the most important criterion that should be considered for selecting a suitable data analytic platform for WM. The data analytic platform alternatives performance assessment using the aforementioned criteria unveiled that KNIME is the suitable data analytic platform that should be used in manufacturing organisations to achieve WM. This article provide a decision assessment framework for production managers in manufacturing organisations to make the right decision when selecting data analytic platform to achieve WM. Simulation of the WMS framework using the KNIME data analytic platform should be explored in future studies.

References

Abrahams, A.S., Jiao, J., Fan, W., Wang, G.A., Zhang, Z.: What’s buzzing in the blizzard of buzz? Automotive component isolation in social media postings. Decis. Support Syst. 55(4), 71–882 (2013)

Abrahams, A.S., Jiao, J., Wang, G.A., Fan, W.: Vehicle defect discovery from social media. Decis. Support Syst. 54(1), 87–97 (2012)

Abramovici, M.: Future trends in product lifecycle management (PLM). In: Krause, F.L. (ed.) The Future of Product Development, pp. 665–674. Springer, Heidelberg (2007). https://doi.org/10.1007/978-3-540-69820-3_64

Bogue, R.: Towards the trillion sensors market. Sens. Rev. 34(2), 137–142 (2014)

Costanzo, A., Faro, A., Giordano, D., Spampinato, C.: Implementing cyber physical social systems for smart cities: a semantic web perspective. In: 2016 13th IEEE Annual Consumer Communications & Networking Conference (CCNC), pp. 274–275. IEEE (2016)

Ding, K., Jiang, P.: Incorporating social sensors and CPS nodes for personalized production under social manufacturing environment. Procedia CIRP 56, 366–371 (2016)

Gola, A., Świć, A.: Directions of manufacturing systems: evolution from the flexibility level point of view. In: Innovations in Management and Production Engineering, Oficyna Wyd. Polskiego Towarzystwa Zarządzania Produkcją, Opole, pp. 226–238 (2012)

Hernández-del-Olmo, F., Gaudioso, E., Duro, N., Dormido, R.: Machine learning weather soft-sensor for advanced control of wastewater treatment plants. Sensors 19(14), 31–39 (2019)

Liu, Z., Yang, D.S., Wen, D., Zhang, W.M., Mao, W.: Cyber-physical-social systems for command and control. IEEE Intell. Syst. 26(4), 92–96 (2011)

Louridas, P., Ebert, C.: Embedded analytics and statistics for big data. IEEE Softw. 30(6), 33–39 (2013)

Minanovic, A., Gabelica, H., Krstić, Ž.: Big data and sentiment analysis using KNIME: online reviews vs. social media. In: 2014 37th International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), pp. 1464–1468. IEEE (2014)

Negrut, V.: Power BI: effective data aggregation. Quaestus Multidisc. Res. J. 13, 146–153 (2014)

Neyeloff, J.L., Fuchs, S.C., Moreira, L.B.: Meta-analyses and Forest plots using a microsoft excel spreadsheet: step-by-step guide focusing on descriptive data analysis. BMC. Res. Notes 5(1), 1–6 (2012). https://doi.org/10.1186/1756-0500-5-52

Saaty, T.L.: Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 1(1), 83–98 (2008)

Sheth, A., Anantharam, P., Henson, C.: Physical-cyber-social computing: an early 21st century approach. IEEE Intell. Syst. 28(1), 78–82 (2013)

Smirnov, A., Kashevnik, A., Ponomarev, A.: Multi-level self-organization in cyber-physical-social systems: smart home cleaning scenario. Procedia CIRP 30, 329–334 (2015)

Taraldsen, K., Chastin, S.F., Riphagen, I.I., Vereijken, B., Helbostad, J.L.: Physical activity monitoring by use of accelerometer-based body-worn sensors in older adults: a systematic literature review of current knowledge and applications. Maturitas 71(1), 13–19 (2012)

Xiong, G., et al.: From mind to products: towards social manufacturing and service. IEEE/CAA J. Autom. Sin. 5(1), 47–57 (2017)

Xiong, G., et al.: Cyber-physical-social system in intelligent transportation. IEEE/CAA J. Autom. Sin. 2(3), 320–333 (2015)

Yao, X., Jin, H., Zhang, J.: Towards a wisdom manufacturing vision. Int. J. Comput. Integr. Manuf. 28(12), 1291–1312 (2015)

Yao, X., Zhou, J., Lin, Y., Li, Y., Yu, H., Liu, Y.: Smart manufacturing based on cyber-physical systems and beyond. J. Intell. Manuf. 30(8), 2805–2817 (2019). https://doi.org/10.1007/s10845-017-1384-5

Yin, D., Ming, X., Zhang, X.: Understanding data-driven cyber-physical-social system (D-CPSS) using a 7C framework in social manufacturing context. Sensors 20(18), 5319–5331 (2020)

Zeng, J., Yang, L.T., Ma, J.: A system-level modeling and design for cyber-physical-social systems. ACM Trans. Embed. Comput. Syst. (TECS) 15(2), 1–26 (2016)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Zeferino, E.F., Mpofu, K., Makinde, O., Ramatsetse, B. (2023). Establishment of an Appropriate Data Analytic Platform for Developing a Wisdom Manufacturing System Using Decision Techniques. In: Kohl, H., Seliger, G., Dietrich, F. (eds) Manufacturing Driving Circular Economy. GCSM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-28839-5_70

Download citation

DOI: https://doi.org/10.1007/978-3-031-28839-5_70

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-28838-8

Online ISBN: 978-3-031-28839-5

eBook Packages: EngineeringEngineering (R0)