Abstract

The development of new advanced material of α-Al- carbon nanotubes (CNTs and green synthesis silver nanoparticles (GAgNPs) superconductor nanocomposites was sudied. Green synthesis silver nanoparticles (GAgNPs) was used for the decoration of CNTS. The composites were by modified spark plasma sintering (SPS). The microstructure, strength and electrical conductivity of the nanocomposites were determined. The formation of sub-grain in the Al-4%CNTs + 2%GAg.NPs composite generates more dislocation density. The addition of GAgNPs to Al-CNTs significantly enhanced the ductility mode of fracture associated with the AlAg3(110) and AlAg2(100) phases and the small sub-grain formed at the surface. It can be concluded that a higher strength, electrical conductivity can be made from the developed nanocomposite.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Effort has been made by the researcher to develop an aluminum conductor that has high strength and electrical conductivity [1]. A carbon nanotube (CNTs) is one of the nanoparticle’s electrical conductive reinforcement that attracts researchers’ attention due to the high electrical conductivity of CNTs on aluminum [2]. The mechanical properties, microstructure, and corrosion of Al-CNTs produced by spark plasma sintering were investigated by Ujah et al [3]. They observed higher strength overhead transmission conductor. Ujah et al [4] reported the electrical conductivity, thermal, wear properties, and microstructure of Al-CNTs produced by spark plasma sintering. They observed high wear resistance; electrical conductivity and thermal properties of overhead transmission conductor. Mansoor and Shahid [5] used the induction melting method to developed Al-CNTs. They observed 77 and 52% enhancement in yield and tensile strength.

Although with the high electrical conductivity and thermal of CNTs there is a dispersion of entanglement of the CNTs during the production and the high cost of CNTs limits their use in electronic devices [6]. A great shear force is usually needed to help disperse CNTs and avoid entanglement in the metal matrix [7]. This limitation is still a challenge in the development of Al/CNTs composites. Ultrasonic cavitations, wet mixing, and metallic nanoparticles have been used to enhance the dispersion of CNTs in aluminum by decreasing the Van der Waals and hydrogen bond interactions. The addition of silver nanoparticles (AgNPs) [8] has been successful used with CNTs to produced conductive composites. Saif et al [9] reinforced on Al-1%CNTs with 0, 1, 2, 3,4% AgNPS and Cu. From the review above on the improvement of the electrical conductivity of Al/CNTs using AgNPs, it was cleared that AgNPs have a great potential in enhancing the properties of Al/CNTs. But the high demand and cost of AgNPs have been a major problem, which reduced the wide application of AgNPs to improves the properties of Al/CNTs [10,11,12,13]. However, in this work attempt was made to produce AgNPs using the biosynthesis method (Cashew leaves extract) to lower the cost of AgNPs used in the production of Al/CNTs.. Researchers [10, 11] have shown that the leaves extract from Cashew has anacardic acids which have been used as antibacterial agents (Ag+ to Ag) in the production of AgNPs [10]. The utilization of leaves extract from Cashew to produce Ag-nanoparticles will be less costly and environmentally friendly. Spark plasma sintering (SPS) was used in the production of the advanced composites. The choice of SPS in this work is regarding the ability to obtain high densification, save time, energy, and elimination coarse grain size [3, 4].

2 Methodology

The aluminum powder was purchased in Lagos Nigeria. The aluminum powder has 99.98% purity. A multi-walled CNTs with a diameter of 10–40 nm and length 10-20 µm used in this work was obtained from Hongwu Company in China. Cashew leaves extract was put inside ethanol (100 ml) for one (1) hour and then 100 ml of AgNO3 was then added to the ethanol solution and left for 30 min for reaction to take place. The samples and the solution were heated to a temperature of 100 oC under constant stirring of speed (2000 rpm). The centrifuge was then used to obtain the solid GAgNPs [10]. The particle size of the GAgNPs was 45 nm. Al-CNTs+2%GANPs were ball milled using a high-speed vibrating ball mill. The ball milling machine contains fifty (50) tungsten balls of 10mm diameter. The production of the advanced composites was done by a spark plasma sintering machine (SPS) (model: SPS10-3). A composite of Al-x%CNTs (x = 1, 2, 3, 4) and constant 2%GAgNPs were produced. Kaise insulation test (model SK5010) was used to determine the electrical conductivity measurement of the composites. The microstructure obtained in the composites was determined using scanning electron microscope (SEM) model: A VEGA 3 TESCAN. The tensile test was done by ASTM D3039 using a Testometric universal testing machine.

3 Results and Discussion

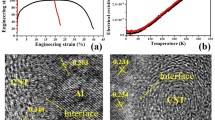

The electrical conductivity of the samples is displayed in Figure 1. It was observed that there was a significant improvement in the electrical conductivity of Al-CNTs and Al-CNTs + GAgNPs. A linear increment in the electrical conductivity as the % of CNTs and GAgNPs increases in the formulation was observed. The increment in the electrical conductivity of Al-GAgNPs+CNTs than Al-CNT was attributed to the higher electrical conductivity of GAgNPs [10] than that of the CNTs. The GAgNPs+CNTs can be used as a conducting reinforcement with a high aspect ratio with lower contact resistance at CNTs junctions. The electrical conductivity of the α-Al has been enhanced from 2.18 × 107S/cm to 2.35 × 107 S/cm for Al-4%CNTs and 4.21 × 107 S/cm for Al-4%CNTs-2%GAgNPs respectively. A 7.8% and 93.11% raise in the electrical conductivity achieved at Al-4%CNTs and Al-4%CNTs-2%GAgNPs over that of Al-matrix. The work had shown a higher electrical conductivity than the work of Ujah et al [4] that reported 2.27x107S/cm for Al-4%CNTs composite. The addition of 2%GAg.NPs to Al-4%CNTs can be used in the production of high-tension transmission conductors.

The stress-strain curves were obtained for the Al-matrix, Al-4%CNTs, Al-4%CNTs+2%GAgNPs are displayed in Fig. 2. In Fig. 2, it was evident that the pure Al has the lowest region under the stress-strain curve than the composites (compared Fig. 2a with Fig. 2b–c). That means that the nanocomposites have higher toughness than the pure Al as revealed by the values of energy absorbed before fracture and percentage of strain (Table 1). The stiffness of Al-matrixes was enhanced as a result of the addition of CNTs +GAgNPs. Al-4%CNTs+2%GAgNPs have a higher strength of all the samples. For example, a tensile strength of 113.43, 157.70, and 206.60MPa were obtained for the Al-matrix, Al-4%CNTs, Al-4%CNTs+2%GAgNPs, respectively. An 82.14% enhancement in tensile strength was recorded at Al-4%CNTs+2%GAgNPs over pure Al. The fracture mechanism of the tensile strength was done by SEM analysis. From the SEM images displays in Figure 3, it was revealed that the fracture mechanism of the α-Al consists of a mixture of both brittle-ductile fractures with transgranular cleavage and tear with ridges (Figure 3a). The nanocomposites have a different mode of fracture from the α-Al. The nanocomposite carbon particles with intercrystalline, without delamination of the particles at interfaces were observed for the Al-4%CNTs nanocomposite (Figure 3b). The addition of 2%GAgNPs to Al-4%CNTs significantly enhances the ductility mode of fracture (Figure 3c).

EM: elastic modulus, YS: yield strength, TS: tensile strength, SB: strain at break, EB: energy at break, ELB: elongation at break.

4 Conclusions

A new nanocomposites Al-CNTs + GAgNPs was developed using the biosynthesis AgNPs from Cashew leaves extract to decorated CNTs. it can be concluded that: Al-GAgNPs + CNTs can be used to conduct reinforcement with a high aspect ratio with lower contact resistance at CNTs junctions. 7.8% and 93.11% raises are obtained the electrical conductivity of Al Al-4%CNTs and Al-4%CNTs + 2%GAgNPs composites. An 82.14% enhancement in tensile strength was recorded et al.-4%CNTs + 2%GAgNPs over pure Al. High tension conductor application can be made with these materials since the values of strength and factor of safety are within the recommended standard.

5 Disclosure Statement

Conflict of Interest: The authors declare that there are no conflicts of interest.

References

Park, S.H., et al.: Modeling the electrical resistivity of polymer composites with segregated structures. Nature Commun. 10, 2537 (2019). https://doi.org/10.1038/s41467-019-10514-4

Bandaru, P.R.: Electrical properties and applications of carbon nanotube structures. J. Nanosci. Nanotechnol. 7, 1239–1267 (2007). https://doi.org/10.1166/jnn.2007.307

Ujah, C.O., Popoola, A.P.I., Popoola, O.M., Aigbodion, V.S.: Influence of CNTs addition on the mechanical, microstructural, and corrosion properties of Al alloy using spark plasma sintering technique. Int. J. Adv. Manuf. Technol. 106, 2961–2969 (2020). https://doi.org/10.1007/s00170-019-04699-7

Ujah, C.O., Popoola, A.P.I., Popoola, O.M., Aigbodion, V.S.: Enhanced tribology, thermal and electrical properties of Al-CNT composite processed via spark plasma sintering for transmission conductor. J. Mater. Sci. 54, 14064–14073 (2019). https://doi.org/10.1007/s10853-019-03894-x

Mansoor, M., Shahid, M.: Carbon nanotube-reinforced Aluminum composite produced by induction melting. J. Appl. Res. Technol. 14, 215–224 (2016). https://doi.org/10.1016/j.jart.2016.05.002

Mohammed, S.M., Chen, D.L.: Carbon nanotube-reinforced Aluminum matrix composites. Adv. Eng. Mater. 22, 1901176 (2020). https://doi.org/10.1002/adem.201901176

Zhang, X.M., Yang, X.L., Wang, K.Y.: Electrical conductivity enhancement of epoxy by hybrid carbon nanotubes and self-made silver nanoparticles. Fibers Polym. 20(7), 1480–1485 (2019). https://doi.org/10.1007/s12221-019-8640-6

Saif, S.S., Ahmed, S.R., Annaz, A.A.: Mechanical performance of micro-Cu and Nano-Ag reinforced Al-CNT composite prepared by powder metallurgy technique. Mater. Res. Express 6, 105071 (2019)

Sharma, M., Pal, H., Sharma, V.: Electrical conductivity and thermal expansion measurement of Nanocrystalline aluminum reinforced with functionalized multiwall carbon nanotubes. Int. J. Chem. Tech. Res. 6, 2057 (2014)

Aritonang, H.F., Koleangan, H., Wuntu, A.D.: Synthesis of silver nanoparticles using aqueous extract of medicinal plants’ (impatiens Balsamina and Lantana Camara) fresh leaves and analysis of antimicrobial activity. Int J Microbiol 2, 8642303 (2019)

Hemlata Meena, P.R., Singh, A.P., Tejavath, K.K.: Biosynthesis of silver nanoparticles using Cucumis Prophetarum aqueous leaf extract and their antibacterial and Antiproliferative activity against cancer cell lines. ACS Omega 5, 5520–5528 (2020)

Ashok Gandhi, R., Jayaseelan, V., Palani Kumar, K., Raghunath, B.K., Krishnaraj, S.: Effect of carbon nano tubes (CNT) on hardness of polypropylene matrix. In: Lakshminarayanan, A., Idapalapati, S., Vasudevan, M. (eds.) Advances in Materials and Metallurgy. Lecture Notes in Mechanical Engineering, pp. 261–270. Springer, Singapore. https://doi.org/10.1007/978-981-13-1780-4_26

Gandhi, R.A., Jayaseelan, V., Raghunath, B.K., Palanikumar, K., Ramachandran, S.: Nano indentation hardness testing of PP-CNT Composites. Mater. Today: Proc. 16, 1372–1377 (2019)

Acknowledgement

The author hereby appreciates and acknowledge the Africa Centre of Excellence for Sustainable Power and Energy Development, ACE-SPED, University of Nigeria, Nsukka, Energy materials research group, University of Nigeria, Nsukka, Nigeria, Faculty of Engineering and Built Environment, University of Johannesburg, Auckland Park, South Africa for their support.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Aigbodion, V.S. (2023). High Strength and Electrical Conductivity of α-Al-CNTs + GAgNPs Nanocomposites. In: Kohl, H., Seliger, G., Dietrich, F. (eds) Manufacturing Driving Circular Economy. GCSM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-28839-5_30

Download citation

DOI: https://doi.org/10.1007/978-3-031-28839-5_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-28838-8

Online ISBN: 978-3-031-28839-5

eBook Packages: EngineeringEngineering (R0)