Abstract

The development of innovative cooling lubrication strategies is significantly driven by the need to machine materials resistant to high temperatures while taking into account both ecological and economic aspects. Cryogenic minimum quantity lubrication (CMQL) represents a compromise satisfying both efficiency and sustainability in the manufacturing process. A minimal amount of oil is added to the cryogenic medium carbon dioxide (CO2) to ensure both cooling and lubrication during tool engagement. In this context, vegetable oils, so-called triglycerides, can be used with respect to the cooling lubrication concept. The aim of this paper is to analyze various bio-based oils with regard to their solubility, spraying and flow behavior and to investigate the influence of additives on the performance. During the lubrication tests, the additives have shown no influence on the lubricating effects. Thus the chemical properties of the base oils primarily influence the properties with regard to solubility and spray behavior. Finally, the collected results were correlated with machining tests showing only a limited correlation with the aforementioned lubrication tests.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

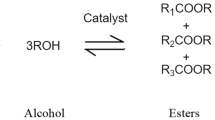

In order to meet the growing demands on machining in the form of cutting high-temperature steels and alloys in the future, cooling lubrication is a central point of reference. Since conventional cooling lubrication strategies have a negative impact on economic and ecological factors as well as on the health of the user, CMQL adds a minimal amount of oil to the cryogenic medium CO2 in order to ensure not only cooling of the contact zone but also sufficient lubrication. The CO2, which has a nozzle outlet temperature of T = −78.5 ℃, can be combined with bio-based oils, for example with triglycerides. To optimize the tribological properties of these bio-based oils, they can be mixed with additives. In order to become aware of the properties of the two media CO2 and oil on the way to the tool cutting edge, selected lubricant tests will be carried out in this study. A possible influence of the lubricant additives sulphur and phosphor on the sprayability and solubility of the lubricant will also be investigated.

2 State of the Art

This chapter provides a brief overview of the state of the art on bio-based lubricants and their additives. Furthermore, the solubility of bio-based oils in CO2 and their benefits for CMQ are discussed in more detail.

2.1 Bio-Based Lubricants

Biological lubricants are a sustainable alternative to mineral-based end products. According to DIN 1607, the proportion of renewable raw materials in a lubricant must be at least 25 percent to qualify as biological. Furthermore, the biodegradability of the lubricating oils must be more than 60 percent, which is positively influenced by short carbon chain lengths, for example. In addition, it is possible to add toxic additives to bio-based oils, which do not correspond to a biological origin [1, 2].

2.2 Characterization of Lubricant Additives

Extreme pressure (EP) additives and anti-wear (AW) additives are the most relevant representatives of additives that act chemically on the surface. These additives consist on the one hand of a polar component, which actively contacts the surface of the workpiece, and on the other hand of a carbon chain, which determines the solubility of the additive in water [3].

EP additives were specially developed for applications involving high temperature and pressure ranges and form an additional lubricating film in the contact zone by means of chemical compounds. AW additives also bind chemically to the molecular structure of metallic surfaces and thus form a stable protective layer, which prevents premature wear [4, 5] . In the context of this publication, the two components sulphur and phosphor are added to the biological base oils and in addition, chlorine or solids are also typical lubricant additives. Sulphur belongs to the category of EP additives, whereas phosphor corresponds to an AW additive. The various components in the additives each have specific temperature ranges, referred to as activation temperatures, in which they reliably reduce friction within the contact zone. Accordingly, sulphur is active in the temperature range between 500 ℃ and 1000 ℃, whereas phosphor effectively reduces friction between 200 ℃ and 900 ℃ [6, 7].

2.3 Solubility of Bio-Based Lubricants in CO2

In order to be able to understand the processes during the joint feed of the media CO2 and bio-based oil, the solubility of the two media is relevant in the case of a one-channel CMQL-system. In general, the interaction between the molecules, the so-called polarity, is decisive for the solubility. Accordingly, polarity describes a charge shift within a molecule, which in the case of polar substances leads to a permanent spatial charge separation in the form of continuously acting dipoles. In summary, it can be stated that polar substances dissolve well in polar solvents and, conversely, non-polar substances dissolve well in non-polar solutions. In addition to polarity, temperature also influences the solubility behavior. High temperatures promote the solubility of solids and liquids, but reduce the solubility of gaseous media in liquid substances. Depending on the thermodynamic state variables pressure p, temperature T or volume V, the state of the mixture can be determined as a function of the mass fractions involved. In addition to a homogeneous mixture, a miscibility gap usually occurs at certain mass fractions and temperatures. If this is the case, the two media are present as separate phases in a heterogeneous mixture [8].

The dissertation by Jörg Fahl can be mentioned as basic research in the field of solubility of various lubricants in CO2. He recognized that the mixing behavior of the two media oil and CO2 is influenced not only by polarity and permittivity (polarizability) but also to a large extent by the structure of the lubrication oils [9].

In his publication «Media Flow Analysis of Single-Channel Pre-Mixed Liquid CO2 and MQL in Sustainable Machining», Grguras describes the application-related investigation of two lubricants (non-polar and polar) with regard to solubility in CO2. The non-polar oil dissolved better in LCO2 than the polar oil. Also, smaller droplet size after nozzle exit could be observed with the non-polar lubricant [10].

In previous studies of the REP chair, the influence of ten bio-based base oils on sprayability and solubility with CMQL has already been investigated with the help of specially developed high-pressure cells. It was shown that the solubility is not determined by the polarity alone [11].

2.4 CMQL with Bio-Based Lubricant

CMQL represents a combination of cryogenic cooling and minimum quantity lubrication technology. CO2 is used as the cryogenic medium in this investigation. Together with LN2, CO2 represents the most common cryogenic media in machining. The starting point of CO2 for CMQL is in riser bottles in which a pressure of p = 57.3 bar and room temperature prevails. This condition is below the critical point on the vapor pressure curve. Consequently, both liquid CO2 (LCO2) and gaseous CO2 can be identified within the feed line. During nozzle exit, another cooling effect occurs, which is known in science as the Joule-Thomson effect. This is based on the expansion of a throttled gas whereby the CO2 further loses temperature. [12].

In order to be able to feed the bio-based lubricant and the cryogenic medium CO2 to the processing zone in a single channel, a CMQL mixing unit was developed in 2015 at the REP department, which enables a single-channel hybrid supply of the two media. In his publication «Milling of Ti6Al4V with carbon dioxide as carrier medium for minimum quantity lubrication with different oils», Gross investigated eight different oils in single-channel application with CO2. In addition to fatty alcohols, mineral oils, synthetic and natural esters were also used. With vegetable and natural esters, the longest tool life was achieved with CMQL [13]. The investigations on the use of bio-based oils for CMQL were continued in detail at the REP Chair and the influence of the oils and their additivation on drilling, milling and turning of stainless steel and roller bearing steel is examined. There is high potential in the use of natural esters for CMQL compared to conventional flood cooling with regard to tool life, wear and forces [14, 15].

3 Experimental Setup

In this chapter, the experimental setup for the solubility and sprayability tests is described. Furthermore, the CMQL system used and the oils investigated are explained.

3.1 CMQL-System and Oils

The CMQL system, developed at the REP, consists of an HPLC pump (oil flow regulation), a coriolis sensor (CO2 flow measurement) and an oil reservoir and operates at approx. 57 bar. It is described in «Hybrid supply system for conventional and CO2/MQL-based cryogenic cooling» [16]. In course of this lubricant investigations, 17 additivated test oils are compared experimentally. Eight base oils form the basis for the various additivated configurations. The base oils can be assigned to the groups: hydrocarbons (KW), natural esters (NE) and synthetic esters (SE). The natural esters used consist of rapeseed, coconut and sunflower oil. For additivation, the base oils are mixed with various proportions and types of sulphur and phosphorus additives. Table 1 (right) lists the additives involved. If a certain component of the additive is crossed twice in a column of a test oil, this indicates that two different variants of additives, based on the identical ingredient, are contained. The comparison of the additivated oils with the respective base oil from Table 1 (left) allows to identify the influence of the additivation.

3.2 Solubility and Sprayability

With the aid of high-pressure view cells developed at the REP Institute, it is possible to investigate the solubility during a single-channel supply of the two media oil and CO2 in static and dynamic state. For the visualization of dynamic miscibility and flow behavior, the high-pressure view cell is used and investigated in a coupled experimental setup with the free jet nozzle for the investigation of the sprayability.

The static cell has a volume of V = 1 ml. The sight glasses mounted on both sides allow observation and documentation of the solubility behavior within the cell. Figure 1 (left) shows the experimental setup, as well as a detailed view of the chamber. For the experiment, the cell is filled with Voil = 0.2 ml and the remaining volume consists of VLCO2 = 0.7 ml and an estimates gaseous fraction of VCO2 = 0.1 ml based on a filling line. A separation layer between liquid and gaseous CO2 confirms the existence of the two phases. To accelerate the dissolution process, the cell is shaken after filling for 10 s.

This combination of the dynamic solubility and the spray pattern test results in an increased significance of the test results, since the sprayability can be directly related to the flow behavior in the dynamic cell. Figure 1 (right) illustrates this test setup. Both sub-tests are documented with separate high-speed cameras. The parameters are summarized in Fig. 1. The nozzle outlet diameters are also varied (di = 0.2 mm/0.3 mm).

4 Results

Finally, the results of the solubility and sprayability studies are described. After that, the results are correlated with tool life tests of a milling process.

4.1 Solubility and Sprayability

Complete solubility of the synthetic esters is observed in the static cell. Furthermore, a partial solubility of selected oils in LCO2 or no solubility of the two media in each other can be observed. Figure 2 (left) compares the three observed states. With the exception of SE 1101, all synthetic esters dissolve completely in LCO2. The additivation of the base oils does not seem to exert any direct influence with regard to solubility. The corresponding base oil is always placed in the identical category as the additivated configurations. The results from the test series with the dynamic cell are characterized by a specific phenomenon: for the test oils based on rapeseed and sunflower oil, a slower laminar boundary flow of oil was observed when the test was carried out with the nozzle di = 0.2 mm. The boundary flow has a sawtooth shape and the tips are carried along impulsively by the passing main-flow. The additivation has no effect on this, since it occurred with identical intensity when using the related base oil. It can be stated that the test oils with the highest dynamic viscosity are also involved in this phenomenon.

During the tests with the nozzle di = 0.3 mm, no boundary flow was observed with the lubricants concerned. Thus, it appears that not only the viscosity determines a boundary edge flow but also the flow velocity. The velocity can be increased from approx. v = 1 m/s to approx. v = 2.5 m/s by changing the nozzle. Figure 2 (right) compares two exemplary flows for the test with the free jet nozzle di = 0.2 mm.

The collected data can be used to classify the main jet length and the uniformity of the spray pattern for the various lubricants. Furthermore, the formation of mist behind the jet and large visible oil droplets can be used to draw conclusions about the atomization capability of a lubricant. A direct correlation between the previously discussed boundary flow in the dynamic cell and the large oil droplets falling sideways in the free jet can also be established. The oil drops, deposited at the boundary in the dynamic cell, do not mix sufficiently with the main-jet after impulsive entrainment by the main-jet up to the nozzle outlet and because of this the oil droplets fall off laterally after the nozzle outlet. Consequently, this phenomenon could not be observed in the free jet test with nozzle with di = 0.3 mm, since no boundary flow could be detected in the cell, it can be assumed that the flow velocity is a decisive factor for the formation of the laminar boundary flow. It repeatedly becomes clear that also with regard to the observations in the spray pattern test, no concrete influence of the additives can be determined.

4.2 Correlation with Milling Process

In general, it can be determined that the bio-based lubricants in combination with CMQL provide a better result than the reference test with emulsion (MWF) and flood cooling. Figure 3 shows the tool life diagram for a correlation of the lubricant tests with the machining series performed. For each additivated lubricant, the tool life achieved with the corresponding base oil is shown in yellow.

The effectiveness and influence of the additives, on the other hand, cannot be clearly clarified for this process. For example, in the case of sunflower oil, a higher tool life could be achieved with the base oil (NE 03) than with the additivated configurations (NE 03(xx)). A correlation with the lubricant tests can also only be established to a limited extent. Exemplarily, the complete solubility of the synthetic esters in the static view cell does not seem to exert any direct influence on the effectiveness during machining. Thus, in the case of the synthetic esters, the polarity of the lubricant can also be discussed. This turns out to be slightly polar or polar for the lubricants treated in this study. Accordingly, a better solubility of non-polar lubricants in LCO2 cannot be confirmed. With regard to machining, the solubility of the lubricant used in CO2 generally does not appear to have any effect on the performance of the machining process.

5 Summary

Hydrocarbons (KW 01(xx), KW 02(xx)) partially dissolved in CO2. With the help of additives, the result could be improved for milling with external cooling. Natural esters based on rapeseed oil (NE 01(xx)) and sunflower oil (NE 03(xx)) provide an intensive oil application and, at low flow rates, exhibit a boundary flow of oil deposited at the edge in the dynamic cell. In contrast, lubricants from the less viscous coconut oil (NE 02(xx)) atomize very intensively. The investigated synthetic esters (SE 01(xx), SE 09(xx)) atomize just as intensively and also exhibit complete solubility in the static cell. A direct influence of the results of the spray and miscibility tests on the machining could not be determined. However, when using CMQL and especially when using bio-based lubricants, the selected process and cooling lubrication parameters have a significant influence on tool life in machining [15].

References

Fachagentur Nachwachsende Rohstoffe e.V. Bioschmierstoff-Kongress, Gülzow (2015)

Redetzky, M.: Wirkmechanismen, Eigenschaften und Leistungsfähigkeit mikrobiell basierter Kühlschmierstoffe in der spanenden Fertigung. Dissertation (2017)

Mang, T. (Hrsg.), et al.: Lubricants and Lubrication.Wiley-VCH Verlag, Weinheim (2017)

Pirro, D.M. (Hrsg.), et al.: Lubrication Fundamentals. Boca Raton, London, New York (2016)

Torbacke, M. (Hrsg.), et al.: Lubricants: Introduction to Properties and Performance (2014)

Kassack, J.F.K.: Einfluß von Kühlschmierstoff-Additiven auf Werkzeugverschleiß Zerspankraft und Bauteilqualität (1994)

Srivastava, S.P. (ed.): Wiley, Hoboken, NJ (2014)

Czeslik, C., et al.: Basiswissen Physikalische Chemie, Wiesbaden (2010)

Fahl, J.: Entwicklung und Erprobung von Schmierölen für Kälte- und Klimasysteme mit CO2 als Arbeitsstoff. Ruhr-Universität Bochum, Fakultät für Maschinenbau (2002)

Grguras D., et al.: Media flow analysis of single-channel pre-mixed liquid Co2 and MQL in sustainable machining. J. Mech. Eng. 67, 1–2 (2021)

Meier, T., et al.: Comparison of sprayability and solubility of bio-based lubricants with liquid carbon dioxide. MM Sci. J. (2021)

Pursell, M.: Experimental investigation of high pressure liquid CO2 release behavior Health and Safety Laboratory. In: Symposium Series, no. 158 (2012)

Gross, D., Blauhöfer, M., Hanenkamp, N.: Milling of Ti6Al4V with carbon dioxide as carrier medium for minimum quantity lubrication with different oils. Procedia Manufacturing 43, 439–446 (2020). https://doi.org/10.1016/j.promfg.2020.02.190

Meier, T., Gross, D., Hanenkamp, N.: Investigation of lubricating oils from renewable resources for cryogenic minimum quantity lubrication. MM Sci. J. 2021(5), 5069–5076 (2021). https://doi.org/10.17973/MMSJ.2021_11_2021154

Meier, T., Seydaack, M., Gross, D., Hanenkamp, N.: Investigation of the influence of the additivation of a biological metalworking oil in cryogenic machining. Procedia CIRP 105, 694–699 (2022). https://doi.org/10.1016/j.procir.2022.02.116

Hanenkamp, N., Amon, S., Gross, D.: Hybrid Supply system for conventional and CO2/MQL-based cryogenic cooling. Procedia CIRP 77, 219–222 (2018). https://doi.org/10.1016/j.procir.2018.08.293

Acknowledgments

The results are part of the research project "Development of bio-based metalworking oils for cryogenic minimum quantity lubrication". Thanks go to the German Agency for Renewable Resources and the German Federal Ministry of Food and Agriculture for funding the joint project. The consortium consists of REP-Chair FAU Erlangen-Nuremberg, Gühring, EagleBurgmann, Schaeffler, Fuchs, Rhenus and Blaser.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Meier, T., Lermer, M., Gross, D., Hanenkamp, N. (2023). Influence of Additivation of Bio-Based Lubricants on Sprayability and Solubility for Cryogenic Minimum Quantity Lubrication. In: Kohl, H., Seliger, G., Dietrich, F. (eds) Manufacturing Driving Circular Economy. GCSM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-28839-5_16

Download citation

DOI: https://doi.org/10.1007/978-3-031-28839-5_16

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-28838-8

Online ISBN: 978-3-031-28839-5

eBook Packages: EngineeringEngineering (R0)