Abstract

With an expected growth of global waste to 3.40 billion tonnes by 2050 and a circularity today of only 8.6% of the world, the earth’s sustainable resources are being exploited beyond their regeneration capacity. Hence, it is necessary to step away from a take – make – dispose principal and transform from a linear towards a circular economy to close product cycles to optimize resource consumption and reduce waste. Product-Service-Systems (PSSs), based on multiple product life cycles combined with remanufacturing, offer a solution to close product cycles. In such PSS, the responsibility for returning, remanufacturing, and repairing used products remains with the Original Equipment Manufacturer (OEM) and increases its need in (reverse) supply chain activities. Essential factors for (reverse) supply chains are, e.g., determining the distribution network, the location of recovery facilities, the geographical dispersion of the customers, and the information flows between the different stakeholders. In this context, this work proposes a multi-method simulation model to support practitioners in determining the optimal infrastructure for storing, remanufacturing, and repairing the used products regarding economic and ecological target criteria. The applicability of the proposed approach is illustrated through a case study of a white goods manufacturing company. This case study highlights the importance of determining the optimal infrastructure in a (reverse) supply chain in PSS business models.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The consequences of the linear economy, such as anthropogenic climate change, increasing amounts of waste, and growing scarcity of raw materials, transform a circular economy indispensable. Among the multitude of end-of-life strategies, remanufacturing is one of the key elements of a circular economy.

An essential prerequisite for successful remanufacturing is the user’s return of the used products. Although several incentive systems exist to encourage the user to return the product, these are usually associated with a high degree of uncertainty regarding the timing and quantity of the returns and the quality of the used products [1].

Product-service systems (PSS), which can be defined as a “marketable set of products and services capable of jointly fulfilling a user’s need”, are a promising approach to solving this problem [2]. In particular, the user-oriented services form of PSS, where the Original Equipment Manufacturer (OEM) remains the product’s owner, allows for better planning of the remanufacturing processes. Furthermore, these new business models enable OEMs to create new sources of added value and competitiveness while at the same time fostering sustainability [3]. To this end, it is necessary to plan and design the (reverse) supply chain and define the locations and capacities for the collection, return, and remanufacturing of the used products, in addition to the production and distribution of the products.

2 Related Work

Over the past decades, several methods and approaches have been developed addressing (reverse) supply chain network design and facility location problems in circular economy business models [4, 5]. Dominguez et al. [4] explored the impact of the critical decision on (reverse) supply chain performance by comparing centralized and decentralized remanufacturing scenarios. The developed simulation considers different return rates, information transparency levels, and nodes in the reverse supply chain. Lieckens et al. [6] developed a strategic decision support tool for (reverse) supply chain networks by considering the number of locations, capacities, and inventory levels of remanufacturing facilities.

Several articles tackled the problem of solving the facility location problem in (reverse) supply chains by developing mixed-integer programming models [7,8,9]. For example, Aljuneidi and Bulgak [7] developed a model for reverse supply chain networks to minimize carbon emissions and transportation distances.

Despite the importance of identifying the optimal (reverse) supply chain network design, few published works considered the impact of PSS in a circular economy. Bal and Badurdeen [10] presented a multi-objective optimization model considering PSS’ social, environmental, and economic criteria. The study aims to optimize the locations of end-of-life product recovery facilities. An additional paper by Bal and Badurdeen [11] presents a simulation-based optimization approach for (reverse) supply chain network design, comparing a ‘selling’ with a ‘lease and sell’ strategy.

However, existing approaches lack incorporating customer behavior and the stochastic characteristic of product end-of-life regarding the quantity, timing, and quality of the returned products for PSSs’ (reverse) supply chain network design. Hence, this study aims to develop a decision support tool based on multi-method simulation for PSS (reverse) supply chain network design by identifying the optimal locations for recovery operations such as repair and remanufacturing. Based on customer base, repair, and remanufacturing volumes, the simulation model can respond flexibly to environmental changes and help to decide which existing physical infrastructure should be integrated into the (reverse) supply chain. In this context, the simulation model incorporates the stages of manufacturing, use phase, and remanufacturing of a product’s multiple life cycles.

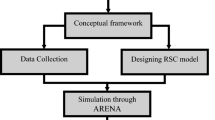

3 Methodology

Many different procedure models for conducting simulation studies can be found in the literature. Nevertheless, almost all procedure models consist of task and system analysis, model formulation, model implementation, model verification, and model application, although the names can vary widely [12].

First, starting from a real or planned system, the task and system analysis are carried out to define the simulation’s objective and describe the system’s elements under consideration, e.g., concerning the level of detail, as a basis for the simulation model [13]. This is followed by the model formulation, in which the creation of a simulation model by abstracting irrelevant characteristics and mapping relevant characteristics takes place [14]. For this purpose, a descriptive concept model is first created, which contains the basic system functions and interactions [15]. The formal or structural model concretizes the conceptual model and is structurally described, e. g., by program flow charts, state transition diagrams, or block diagrams [15, 16]. Next, the model implementation takes place, i.e., creating an executable program, the simulation model, using suitable programming languages [16]. The model verification is used to check if the simulation model contains logical errors (‘semantic correctness’) and if the simulation software or other modeling tools were used according to the specified syntactic rules (‘syntactic correctness’) [17]. This verification and validation is a permanent, iterative process that accompanies all phases of a simulation study [15, 16]. With the model application in the form of simulation experiments, information can then be obtained to explain the behavior of the real system and the future behavior of the modified real system. The results of the simulation experiments are initially formal results that can be used either to adapt the simulation model (‘gaining knowledge’) or to implement it in the real or planned system (‘using knowledge’) [18,19,20]. The simulation results serve as decision support and must be evaluated and processed in a suitable form to enable interpretation [16]. Based on the conclusions for the real system, the cycle is closed, e.g., to adapt the model to new conditions of the real system [21].

4 Case Study

The proposed methodology was applied to a case study with a white goods manufacturing company involved in the EU project ‘Resource-efficient Circular Product-Service-Systems’ (ReCiPSS). The whitegoods company is piloting a PSS offering for 300 washing machines in four markets, i.e., the Netherlands. The washing machine model relevant for the study is a high-end product for heavy-duty applications designed for 30,000 washing cycles. This model is usually in service for seven years on average before users replace the machines for different reasons [22].

To scale up the implementation of PSS, it is planned that during the product lifetime of the washing machine, each washing machine will be remanufactured twice and serve over three life cycles of five years. To support a new business model for washing machines based on multiple life cycles and product remanufacturing, the white goods manufacturing company will require a new (reverse) supply chain infrastructure.

4.1 Task and System Analysis

The multi-method simulation model evaluates the economic and ecological performance of the (reverse) supply chain infrastructure. To determine the optimal infrastructure, the simulation model considers several objective functions to minimize the transport and storage costs, service time, and CO2 emissions of the PSS washing machines during their complete product lifecycle.

The model boundary consists of the geographical location of the value chain stakeholders, namely manufacturer, warehouse, customers, retailers, and remanufacturers, involved in the white goods demonstrator of the ReCiPSS project.

All relevant data for simulation was gathered continuously from 2018 to 2020 in workshops and open-ended interviews with the white goods manufacturing company and their service providers involved. The supply chain-related data, such as the location of facilities (warehouse, retailers), transport costs, and reverse logistics, were collected. In addition, data and assumptions were adopted from Roci et al. [23] to develop the simulation model.

4.2 Model Formulation

A class diagram with its classes, attributes, and relationships was described based on the system analysis, see Fig. 1.

At the core of this class diagram, the Main agent selects individual locations of the manufacturer, warehouse, customers, retailers, and remanufacturers for the (reverse) supply chain. The locations are selected to ensure a high target fulfillment according to the target criteria mentioned in Sect. 4.1. Therefore, the Main agent uses an ADD algorithm to search the solution space to generate an optimal or near-optimal solution (+evaluateLocations ()).

For the calculation, the Main agent needs information about customers, capacity utilization and costs of the locations’ warehouse, and vehicles depending on washing machine orders, repair, and remanufacturing requests. Therefore, each location can calculate their stock level (+calcStockLevel()), and utilization time of the vehicles (+calcUtilizationTime()). The locations receive information about washing machine orders, repair, and remanufacturing requests and allocate them to the vehicles. For the order allocation, a genetic algorithm is applied (+generatePopulation(), +calcFitness(), +mutatePopulation(), +crossoverPopulation(), +selectPopulation()).

For the order allocation, the locations need information about the transportation times, transportation start, and utilization times of the vehicles. Each vehicle is thus able to calculate their transportation start (+calcTransportStart()) and time (+calcTransportTime()) according to their position, speed, and availability. Then, the locations ‘negotiate’ with the vehicles, which can modify the solution based on local knowledge (+mutatePopulation()). Finally, the best-found solution will be taken to allocate the order to the vehicles.

Furthermore, the customers are represented by the Customer agent. The characteristic of the customer differs in the choice of the service package, e.g., contract duration, service level, and behaviors in terms of premature contract termination and subscription renewal.

4.3 Model Implementation and Verification

A multi-method approach comprising the Agent-based and Discrete Event techniques to model the (reverse) supply chain was chosen. Therefore, the AnyLogic Professional 8.7.2 software was selected to develop the simulation model [24].

The simulation model consists of the Agents Main, Manufacturer, Remanufacturer, Warehouse, Retailer, Vehicle, Customer, and Washing Machine. The agents are placed in a geospatial environment defined by the GIS map according to the supply chain configuration of the white goods company. The simulation duration of individual runs was determined statically by a time-related event. The duration of the simulation time was set to fifteen years.

Finally, verification techniques presented in Rabe et al. [12] were implemented during the simulation study. To ensure that the simulation model meets the theoretical requirements, animation using 2D and 3D graphics, trace analysis, extreme-condition test, and face validity with the case company was applied.

4.4 Model Application

Within the model application, the system behavior in the demonstrator phase of the PSS business model for white goods in the Dutch market is analyzed based on the simulation results. For this purpose, the total transport and storage costs, service time, and CO2 emissions of the PSS washing machines in the three scenarios were determined and compared. In scenario one, the customers were distributed in Amsterdam, in scenario two, in Groningen, and in the last scenario, the customers were randomly distributed throughout the country.

Concerning the target figure ‘transport and storage costs’, scenario one with customers in Amsterdam is less expensive than scenario two, with customers in Groningen by ca. 45%. Compared to scenario three, where customers are spread across the whole country, ca. 27% more costs are incurred than in scenario one.

Considering the target figure ‘service time’, the customer requests, e.g., a request for a technician in case of machine failure, can be fulfilled in scenarios one and two within 15 h on average. In scenario three, customers typically have to wait 21 h until their requests are fulfilled. On average, the white goods company’s minimum requirement of fulfilling the customer’s request within 24 h is reached in all three scenarios.

Regarding the target figure ‘CO2-emissions’, ca. 76% of CO2 emissions incurred less in scenario one than in scenario two. Compared to scenario three, 57% more CO2 emissions were incurred than in scenario one.

5 Conclusion and Outlook

Due to different usage patterns and environmental influences, the characteristics of remanufacturing of used products reflect a high uncertainty regarding the product state, the stochastic return time, and the amount of returned products. This complexity ultimately leads to fluctuating capacity utilization and throughput times and high opportunity costs and thus also directly represents a risk to the company’s success.

Therefore, this study proposes a decision support tool based on a multi-method simulation model for PSSs’ (reverse) supply chain network design by identifying the optimal locations for recovery operations such as repair and remanufacturing. Based on the results obtained from the simulation model, the importance of determining the optimal locations for circular PSS business models is highlighted. In the considered scenarios for the Dutch market, scenario one with customers in Amsterdam performed most favorably.

The findings of this study can serve as a basis for further research activities. In this paper, assumptions concerning customer behavior, e.g., subscription duration, usage of the washing machine, or buying behavior, were made due to a lack of publicly available market data. Furthermore, certain input parameters of the model proposed, such as inventory costs, transport costs, or labor costs, are constant over the entire lifecycle. A logical extension would be to relax the deterministic assumption of input data and develop stochastic optimization models. In general, it is to be noted that this study does not consider the success of the business model and the social impact.

Also, a more efficient intelligent algorithm can be designed and compared with the presented algorithm to improve the optimization problem’s solution space.

In addition, further target figures for the future scenario could be introduced, such as qualification and education, wage and salary, and environmental protection.

References

Asif, F.M.A., Bianchi, C., Rashid, A., Nicolescu, C.M.: Performance analysis of the closed loop supply chain. J. Remanufact. 2(1) (2012)

Goedkoop, M.J., van Halen, C.J., te Riele, H.R., Rommens, P.J.: Product Service Systems, Ecological and Economic Basics: Ecological and Economic Basics (1999)

Tukker, A.: Product services for a resource-efficient and circular economy – a review. J. Clean. Prod. 97, 76–91 (2015)

Dominguez, R., Cannella, S., Framinan, J.M.: Remanufacturing configuration in complex supply chains. Omega 101, 102268 (2021)

Deveci, M., Simic, V., Torkayesh, A.E.: Remanufacturing facility location for automotive Lithium-ion batteries: an integrated neutrosophic decision-making model. J. Clean. Prod. 317, 128438 (2021)

Lieckens, K.T., Colen, P.J., Lambrecht, M.R.: Optimization of a stochastic remanufacturing network with an exchange option. Decis. Support Syst. 54(4), 1548–1557 (2013)

Aljuneidi, T., Bulgak, A.A.: Carbon footprint for designing reverse logistics network with hybrid manufacturing-remanufacturing systems. J. Remanuf. 10(2), 107–126 (2019). https://doi.org/10.1007/s13243-019-00076-5

Yan, R., Yan, B.: Location model for a remanufacturing reverse logistics network based on adaptive genetic algorithm. Simulation 95(11), 1069–1084 (2019)

Kilic, H.S., Cebeci, U., Ayhan, M.B.: Reverse logistics system design for the waste of electrical and electronic equipment (WEEE) in Turkey. Resour. Conserv. Recycl. 95, 120–132 (2015)

Bal, A., Badurdeen, F.: A multi-objective facility location model to implement circular economy. Procedia Manuf. 51, 1592–1599 (2020)

Bal, A., Badurdeen, F.: A simulation-based optimization approach for network design: the circular economy perspective. Sustainable Prod. Consump. 30, 761–775 (2022)

Rabe, M., Spiekermann, S., Wenzel, S.: Verifikation und Validierung für die Simulation in Produktion und Logistik: Vorgehensmodelle und Techniken. Springer, Berlin, Heidelberg (2008)

Gutenschwager, K., Rabe, M., Spieckermann, S., Wenzel, S.: Simulation in Produktion und Logistik. Springer, Berlin, Heidelberg (2017)

Eley, M.: Simulation in der Logistik: Einführung in die Erstellung ereignisdiskreter Modelle unter Verwendung des Werkzeuges “Plant Simulation.” Springer Berlin Heidelberg, Berlin, Heidelberg (2012)

Wenzel, S., Collisi-Böhmer, S., Pitsch, H., Rose, O., Weiß, M.: Qualitätskriterien für die Simulation in Produktion und Logistik: Planung und Durchführung von Simulationsstudien. Springer-Verlag, Berlin Heidelberg, Berlin, Heidelberg (2008)

Simulation von Logistik-, Materialfluss- und Produktionssystemen: Grundlagen, 3633-1, VDI Verein Deutscher Ingenieure, Berlin (2014)

Hedtstück, U.: Simulation diskreter Prozesse: Methoden und Anwendungen. Springer Vieweg, Berlin, Heidelberg (2013)

Drews, T.: Zieldeterminierte Gestaltung von Produktionssystemen. Dissertation. Shaker Verlag GmbH, Düren (2019)

Nyhuis, P.: Entwicklungsschritte zu Theorien der Logistik. In: Nyhuis, P. (ed.) Beiträge zu einer Theorie der Logistik, pp. 1–18. Springer-Verlag, Berlin Heidelberg, Berlin, Heidelberg (2008)

Nyhuis, P., Wiendahl, H.-P.: Logistische Kennlinien: Grundlagen, Werkzeuge und Anwendungen, 3rd edn. Springer Vieweg, Berlin (2012)

Balci, O.: How to assess the acceptability and credibility of simulation results. In: Proceedings of the 1989 Winter Simulation Conference, Washington, D.C., United States, pp. 62–71 (1989)

Asif, F.M., Roci, M., Lieder, M., Rashid, A., Mihelič, A., Kotnik, S.: A methodological approach to design products for multiple lifecycles in the context of circular manufacturing systems. J. Clean. Prod. 296, 126534 (2021)

Roci, M., et al.: Towards circular manufacturing systems implementation: a complex adaptive systems perspective using modelling and simulation as a quantitative analysis tool. Sustainable Prod. Consump. 31, 97–112 (2022)

Borshchev, A.: The Big Book of Simulation Modeling: Multimethod Modeling With AnyLogic 6. AnyLogic North America, Chicago (2013)

Acknowledgment

This work has been conducted as part of the ReCiPSS project that has received funding from the European Union‘s Horizon 2020 research and innovation program under grant agreement No. 776577.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Grosse Erdmann, J., Koller, J., Amir, S., Mihelič, A., Döpper, F. (2023). Simulation-Based Analysis of (Reverse) Supply Chains in Circular Product-Service-Systems. In: Kohl, H., Seliger, G., Dietrich, F. (eds) Manufacturing Driving Circular Economy. GCSM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-28839-5_13

Download citation

DOI: https://doi.org/10.1007/978-3-031-28839-5_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-28838-8

Online ISBN: 978-3-031-28839-5

eBook Packages: EngineeringEngineering (R0)