Abstract

Industrial value creation today is characterised in many sectors by globally distributed processes for product manufacturing based on the division of labour in order to achieve advantages through specialisation, scale and location. However, the economic advantages of this form of value creation are being increasingly diminished by the current ecological and social challenges. Local manufacturing has the potential to be a piece of the puzzle in the complex transformation process towards a sustainable circular economy. However, suitable framework conditions are needed for the successful implementation of economically, ecologically and socially sustainable forms of local value creation. To be able to develop these in a targeted manner, knowledge regarding the areas influenceable by societal functional systems (e.g. politics, economy, production) and how they may affect the design dimensions of local manufacturing is necessary. A systems theory-based analysis is used to consider the influence of the operations of societal subsystems on local manufacturing, to identify decision spaces and to evaluate overarching couplings between the societal system operations.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Local manufacturing

- Collaborative value creation

- Sustainable manufacturing

- Circular economy

- System theory

1 Introduction

The utilisation of the principles of a circular economy (CE) is ultimately indispensable to meet the ecological and social challenges of our time (reduction of greenhouse gases, preservation of biodiversity, protection of remaining natural land areas) [1]. Local Manufacturing offers considerable potential to promote the necessary transformation towards a sustainable circular economy, as it contributes to the reduction of value creation cycles (e.g. avoiding overproduction, reducing transport, involving regional stakeholders) [2,3,4]. Modern production technologies (e.g. additive manufacturing, mobile production units) and the digitalisation of the product creation process promote manufacturing for varying scales that adapt to local conditions and needs [2, 5,6,7]. The goal is to produce locally adapted products at the point of need for the current demand by involving regional stakeholders (local producers, knowledge carriers and customers) and resources (recyclable components and materials, materials from local recycling loops) [2, 8]. The current trends of sustainability, individualisation and digitalisation fundamentally improve the potential for the development of local manufacturing. However, the economically successful implementation of competitive business models for patterns of local value creation is not yet foreseeable. The question arises as to which conditions must exist to facilitate the emergence of local value creation patterns and which societal systems (politics, economy, consumption, production, etc.) have an influence on shaping these areas.

2 Current Status and Objective of Research

Within the context of our research [4], the systematics of local manufacturing are investigated to achieve a more in-depth understanding of its internal functionality and to be able to derive recommendations for action in various areas of society. The basis is a sensitivity analysis according to Vester [9]. Based on a systematic analysis of texts dealing with the concepts of Distributed Manufacturing, Urban Manufacturing and Re-Distributed Manufacturing, various factors influencing local manufacturing were found [10]. Furthermore, five main attributes of local manufacturing were identified, which were assigned to three dimensions (location, resources, demands) (see Table 1).

In a next step, the causal interrelations between the identified factors influencing the dimensions of local manufacturing were modelled, thus building a causal network. Subsequently the main chains of influence and ultimately key factors affecting local manufacturing were derived. The strength of the influences in regard to their short-term, medium-term and long-term effects was differentiated [4].

3 Approach for the Determination of Action Areas

Systems theory is a suitable approach for assigning the central influencing factors of local manufacturing to societal sub-areas. According to LUHMANN, a system defines itself by constantly distinguishing itself from its environment [11]. The overall system of modern society is differentiated into functional subsystems (e.g. politics, economy) in order to reduce complexity. Problems that arise can be dealt with in these functional systems [12]. Systems operate autopoietically, i.e. self-referentially, meaning they permanently reproduce themselves and their own structures [11] and can only operate within these self-(re-)produced structures (according to their own logic) [13].

At the same time, however, systems are in a reciprocal exchange and permanent development cycles with their environment through structural couplings [11, 13].

A system is thus adapted to its environment, but can also cause its environment [13]. The functional systems can only operate according to their own logic due to autopoiesis, i.e., the economic system, e.g., can only react economically to political or legal issues [12]. Operations of different functional systems can contradict each other (“operative difference”) [12]. Table 2 shows the six societal functional systems that will be considered in this paper including a short explanation of each one. These systems partly refer to Luhmann's sociologically influenced explanations, but have been extended according to his logic in order to be able to represent the special case of local manufacturing.

According to Luhmann’s System Theory the systems Politics and Law depend on different logics, as shown in Table 2. Nevertheless, there was a large overlap to be found in their influence on the factors of this specific case of local manufacturing. Therefore, they are merged into the system Politics/Law for the rest of this paper.

The next part of the process was assigning the key influencing factors of local manufacturing to six functional systems according to Table 3 in an interdisciplinary workshop. The classification was decided according to the lead question of whether the programmes and results of the functional systems have a direct effect on their respective key influencing factors. Depending on the strength of the factor’s impact on a main attribute of local manufacturing (long-term development perspective) [4], a numerical value from 1 to 5 was assigned to the subsystem in case of a direct effect between functional system and key influencing factor (1 = low… 5 = essential).

The sum of the influences of one functional system on each main attribute of local production, considering the strength of the respective key influencing factors (long-term development perspective), was determined. This value was set in relation to the total amount of all influences of all considered functional systems for each main attribute to show the relative influence of the functional systems (see Table 3: Relative influence of the functional systems).

Based on these evaluations it is possible to compare the relevance of the functional systems’ influences on the main attributes of local manufacturing.

4 Overview Over the Results

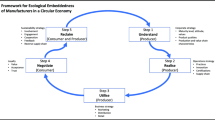

Figure 1 shows the relative influences of the functional systems on the main attributes of local manufacturing in comparison to each other. It becomes clear that the system-dependent influence varies for the different main attributes.

4.1 Production at the Place of Need

The systems under consideration have a generally comparable influence on the dimension of Production at the place of need. However, the systems Politics/Law as well as Economy tend to have a stronger impact.

The system Politics/Law influences production on-site through political decisions and laws to develop local infrastructure and to ensure the availability of production areas (e.g. land use plans, price regulation measures). The system Economy significantly influences the economic valuation of the use of local land and the expansion of local infrastructure for local manufacturing compared to other perspectives of use (housing, recreation, consumption), and thus the decisions regarding investments. The system Production influences Production at the place of need through its production concepts and technologies and their suitability for meeting the requirements of on-site production (cost-efficient manufacturing of small series, manufacturing technologies with little emission to promote acceptance by local residents, machines with little need for space, etc.). The further fulfilment of these requirements is also influenced by technological developments and new knowledge in Engineering and Technology Sciences. The influence of the system Consumption affects on-site production in particular through the demand for locally produced products.

4.2 Utilisation of Local Resources

The utilisation of local resources is also particularly shaped by the influence of the system Politics/Law as well as the system Economy. The former, through its decisions and legislation, significantly impacts the availability and involvement of local human resources (e.g. legislation on immigration, education and training) and enterprises resources (e.g. import restrictions/tariffs, supply chain standards) as well as the suitability of the use and reuse of locally available raw materials, materials, products or components. Based on the legal framework as well as current and expected future market conditions (e.g. local and global availability of raw materials), the system Economy determines the prices and price expectations for local resources (labour and materials). These in turn form an important basis for investment decisions that can promote or restrict the availability and use of local resources (e.g. expansion of structures in the area of recycling or re-manufacturing). The systems Production as well as Engineering and Technology Sciences influence the use of local resources by creating opportunities for the use and reuse of locally available resources, e.g., through technology development, the implementation of CE design and production principles, and the introduction of appropriate processes for a sustainable, local circular economy. The system Consumption has a subordinate influence, which is due to the fact that the fulfilment of benefits is not adversely affected by the reuse of materials and components.

4.3 Addressing of Local Demands

Addressing of local demands through local manufacturing is particularly dependent on the systems Engineering and Technology Sciences as well as Production. Corresponding research activities as well as the implementation of concepts for adaptable and customer-integrating production systems enable product manufacturing in a way that includes the customer in the value creation and identifies their individual requirements as well as it avoids warehousing through a demand-oriented and highly flexible production. The system Consumption shapes this dimension of local manufacturing in so far as its operations of satisfaction of needs depend on the utility dimensions present in the system, which need to be addressed. In the context of local manufacturing, it is relevant that these are not exclusively focused on the functionality and cost of the product (functional-economic value), but also represent benefits through participation in the value creation process (e.g. experience, DIY experience, responsibility) and the addressing of an underlying understanding of value (e.g. ecological requirements) [14]. The system Economy creates the evaluation basis for investment decisions regarding research and design of production in the sense of the demand-oriented, highly flexible and space-minimizing production of goods.

4.4 Structural Coupling of the Systems

In many cases, the central factors influencing local manufacturing are not affected exclusively by one system, but by different systems. From this overlap, the structural coupling of the systems and thus a mutual influence can be derived.

The coupling between the system Politics/Law, the system Economy and the system Production is of great importance. The system Politics/Law creates a framework for local manufacturing through political decisions and corresponding laws. On the one hand, this includes the creation of infrastructural prerequisites for the system Production for it to be able to establish production locally (suitable infrastructure, provision of land for production). On the other hand, this also involves regulations that determine the municipal requirements for production and thus its implementation (e.g. regulations regarding the return and reuse of products). In addition, the system Politics/Law also influences pricing through taxation requirements (e.g. CO2 tax) and thus affects the system Economy and ultimately investment decisions for local manufacturing.

Another central coupling is the link between the system Economy, the system Production and the system Engineering and Technology Sciences. The system Economy has the methods for the economic evaluation of business models. Based on the economic evaluation of the value creation patterns of local manufacturing, the decision-making for investments ensues.

The system Production, the system Engineering and Technology Sciences and the system Consumption are coupled via the influencing factors for recording customer needs and for cooperative product development. The operation of consumption, as an act of prosuming, leads to participation in value creation and thus influences the successful implementation of operations in the system Production.

5 Summary and Discussion

This paper demonstrates that the establishment of local manufacturing requires operations in multiple different societal functional systems. Particularly important are the following functional systems: Politics, Law, Production, Engineering and Technology Sciences, Economy as well as Consumption. The systems are of varying importance to the different dimensions of local manufacturing and display structural couplings among each other. Based on the knowledge of the areas of influence of the systems and their couplings, recommendations for action must now be developed in a next step. These should focus the operations of the subsystems in such a way that they mutually promote the appropriate conditions for a positive development of the dimensions of local manufacturing while also eliminating any operational differences between the functional systems. The cross-system approach supports the development of recommendations for action in so far as those relevant perspectives are not neglected and that the targeted promotion of local manufacturing is facilitated through the system operations of politics, economy, production, research and consumption.

The limitations of this paper lie within the fact that the influences of the individual systems are only represented in relation to each other. Although we were able to show what the central areas of influence of the functional systems on local manufacturing are and thus can provide a certain point of orientation, it is not possible to make a statement about how impactful the respective subsystems are in absolute terms.

References

Larsson, M.: Circular Business Models. Developing a Sustainable Future. Springer International Publishing, Cham (2018)

Srai, J.S. et al.: Distributed manufacturing. Scope, challenges and opportunities. Int. J. Prod. Res. 54 (2016)

Stahel, W.R.: The business angle of a circular economy. Higher competitiveness, higher resource security and material efficiency. In: Webster, K., Blériot, J., Johnson, C. (eds.) A New Dynamic Effective Business in a Circular Economy, pp. 45–60. Ellen MacArthur Foundation, Cowes, Isle of Wight (2013)

Krenz, P., Saubke, D., Stoltenberg, L., Markert, J.: Towards Smaller value creation cycles: key factors and their independencies for local manufacturing. In: 3rd Conference on Production Systems and Logistics (CPSL) (2022)

Lentes, J., Hertwig, M., Zimmermann, N., Mahlau, L.-M.: Development Path for Industrial Enterprises Towards Urban Manufacturing. dtetr (2018)

Halverson, E.R., Sheridan, K.: The Maker Movement in Education. Harvard Educ. Rev. 84(4), 495–504 (2014)

Matt, D.T., Rauch, E., Dallasega, P.: Trends towards distributed manufacturing systems and modern forms for their design. Procedia CIRP 33 (2015)

Moreno, M., Charnley, F.: Can re-distributed manufacturing and digital intelligence enable a regenerative economy? An integrative literature review. In: Setchi, R., et al. (eds.) Sustainable Design And Manufacturing 2016. Smart Innovation, Systems and Technologies, vol. 52, pp. 563–575. Springer , Cham (2016)

Vester, F.: Ausfahrt Zukunft Supplement: Material zur Systemuntersuchung, München (1991)

Krenz, P., Stoltenberg, L., Markert, J., Saubke, D., Redlich, T.: The phenomenon of local manufacturing: an attempt at a differentiation of distributed, re-distributed and urban manufacturing. In: Andersen, A.-L., et al. (eds.) CARV/MCPC -2021. LNME, pp. 1014–1022. Springer, Cham (2022). https://doi.org/10.1007/978-3-030-90700-6_116

Luhmann, N.: Soziale Systeme. Grundriß einer allgemeinen Theorie, 1st edn. Suhrkamp, Frankfurt am Main (1984)

Kneer, G., Nassehi, A.: Niklas Luhmanns Theorie sozialer Systeme. Eine Einführung. UTB, vol. 1751. Fink, München (1993)

Luhmann, N.: Die Gesellschaft der Gesellschaft. Suhrkamp, Frankfurt am Main (1997)

Krenz, P.: Formen der Wissensarbeit in einer vernetzten Wertschöpfung, Dissertation, Helmut-Schmidt-Universität (2020)

Acknowledgements

This research is funded by dtec.bw – Digitalization and Technology Research Center of the Bundeswehr [project: Production Next Door].

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Krenz, P., Stoltenberg, L., Saubke, D., Markert, J. (2023). Identification of Action Areas for the Promotion of Local Manufacturing in Reference to System Theory. In: Kohl, H., Seliger, G., Dietrich, F. (eds) Manufacturing Driving Circular Economy. GCSM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-28839-5_104

Download citation

DOI: https://doi.org/10.1007/978-3-031-28839-5_104

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-28838-8

Online ISBN: 978-3-031-28839-5

eBook Packages: EngineeringEngineering (R0)