Abstract

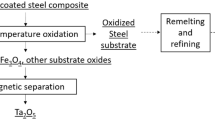

In recent years, tantalum is being increasingly researched as a replacement for coatings for high-temperature applications. Tantalum is a refractory metal with low recycling rate of less than 1% because most tantalum secondary recovery techniques are primarily meant for recovery of other elements. In this study, the objective is to review various potential methods for recycling of tantalum coated steel composite, either at its end of life or for coating refurbishment purposes when coating is damaged. Tantalum can be recovered by both pyrometallurgical and hydrometallurgical methods, or a combination of the two, and it usually involves a whole process development with multiple steps for separation and purification from other elements. The main factor for selecting the best recovery method is dependent on the materials which are mechanically or chemically bonded with tantalum. This review summarizes various methods to recover tantalum from different secondary sources like tantalum capacitors, tantalum mill products, and tantalum in chemical processing industry. Lastly, we comment on the best method to recover tantalum from tantalum coated scrap.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

“Fourth Annual Report on Carcinogens (1985) U.S. Department of Health and Human Services, NTP 85-002, p 85

USGS Report on Tantalum (2022) U.S. Geological Survey, Mineral Commodity Summaries, 2022.

Tantalum-Niobium International Study Center (2020) Beautiful metal. Oxide films on Tantalum and Niobium. TIC Bulletin No 181

Reck BK, Graedel TE (2012) Challenges in metal recycling. Science 337(6095):690–695

Mineta K, Okabe TH (2005) Development of a recycling process for tantalum from capacitor scraps. J Phys Chem Solids 66(2–4):318–321

Fujita T, Ono H, Dodbiba G, Yamaguchi K (2014) Evaluation of a recycling process for printed circuit board by physical separation and heat treatment. Waste Manage 34(7):1264–1273

Katano S, Wajima T, Nakagome H (2014) Recovery of tantalum sintered compact from used tantalum condenser using steam gasification with sodium hydroxide. APCBEE Proc 10:182–186

Lessard JD, Shekhter LN, Gribbin DG, Blagoveshchensky Y, McHugh LF (2015) A new technology platform for the production of electronic grade tantalum nanopowders from tantalum scrap sources. Int J Refract Metal Hard Mater 48:408–413

Vutova K, Vassileva V, Koleva E, Munirathnam N, Amalnerkar DP, Tanaka T (2016) Investigation of tantalum recycling by electron beam melting. Metals 6(11):287

Niu B, Chen Z, Xu Z (2017) Method for recycling tantalum from waste tantalum capacitors by chloride metallurgy. ACS Sustain Chem Eng 5(2):1376–1381

Niu B, Chen Z, Xu Z (2017) Application of pyrolysis to recycling organics from waste tantalum capacitors.“ J Hazard Mater 335:39–46

Niu B, Chen Z, Xu Z (2020) Recycling waste tantalum capacitors to synthesize high value-added Ta2O5 and polyaniline-decorated Ta2O5 photocatalyst by an integrated chlorination-sintering-chemisorption process. J Clean Prod 252:117206

Baba AA, Adekola FA, Faseki M (2005) A study of the kinetics of the dissolution of a Nigerian tantalite ore in hydrochloric acid. Ife J Sci 7(2):221–227

Baba, A. A., F. A. Adekola, O. I. Dele-Ige, and R. B. Bale (2007). “Investigation of dissolution kinetics of a Nigerian tantalite ore in nitric acid.“ Journal of Minerals & Materials Characterization & Engineering 7, no. 1:83–95

Wang X, Zheng S, Xu H, Zhang Y (2009) Leaching of niobium and tantalum from a low-grade ore using a KOH roast–water leach system. Hydrometallurgy 98(3–4):219–223

Nete M, Purcell W, Nel JT (2016) Hydrometallurgical separation of niobium and tantalum: a fundamental approach. Jom 68(2):556–566

Niu B, Chen Z, Xu Z (2017) Recovery of tantalum from waste tantalum capacitors by supercritical water treatment. ACS Sustain Chem Eng 5(5):4421–4428

Chen W-S, Ho H-J, Lin K-Y (2019) Hydrometallurgical process for tantalum recovery from epoxy-coated solid electrolyte tantalum capacitors. Materials 12(8):1220

Micheau C, Lejeune M, Arrachart G, Draye M, Turgis R, Michel S, Legeai S, Pellet-Rostaing S (2019) Recovery of tantalum from synthetic sulfuric leach solutions by solvent extraction with phosphonate functionalized ionic liquids. Hydrometallurgy 189:105107

Deblonde GJ-P, Bengio D, Beltrami D, Bélair S, Cote G, Chagnes A (2019) A fluoride-free liquid-liquid extraction process for the recovery and separation of niobium and tantalum from alkaline leach solutions. Sep Purif Technol 215:634–643

Legeai S, Pellet-Rostaing S (2020) Ionic liquids as extraction media in a two-step eco-friendly process for selective tantalum recovery. ACS Sustain Chem Eng 8(4):1954–1963

Dutta S, Mukhopadhyay S, Gaddam S, Shenoy KT, Mirji KV (2021) Process development for the separation of niobium and tantalum from fluoride medium using trioctyl amine and application of Taguchi's method to optimize solvent extraction parameters. Hydrometallurgy 199:105522

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Gupta, A., Mishra, B. (2023). Tantalum Recovery Technique for Recycling of Tantalum Coated Composite Materials. In: Ouchi, T., et al. Rare Metal Technology 2023. TMS 2023. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-031-22761-5_25

Download citation

DOI: https://doi.org/10.1007/978-3-031-22761-5_25

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22760-8

Online ISBN: 978-3-031-22761-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)