Abstract

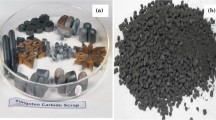

Tungsten (W) is one of the most important metals in various industries, particularly in the machining industry. At least 60% of W is consumed in cemented carbide or super-hard alloys in Japan and the USA. The major recycling method for cemented carbides is the hydrometallurgical process combined with the roasting step, which oxidizes W in scrap into tungsten oxide. However, this conventional process requires repetition of roasting and dissolution in some cases, which makes the process costly and inefficient. In contrast, the molten salt process has specific advantages in terms of processing rate and simplicity. In this study, the recycling processes for W using molten salt are reviewed. Subsequently, our new recycling process using molten hydroxide is introduced, and recent data on this process discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

US Geological Survey (2016) Mineral commodity summaries

JOGMEC (2019) Material flow of mineral resources 2018, Tungsten

Oishi T (2017) Tungsten recycling technologies using Molten salts. Kinzoku 87:771–776 (in Japanese)

Lassner E (1995) From tungsten concentrates and scrap to highly pure ammonium paratungstate (APT). Int J Refract Met Hard Mater 13:35–44

Lassner E, Schubert WD (1999) Tungsten-properties, chemistry, technology of the element, alloys, and chemical compounds. Plenum Publishers, New York, pp 377–385

Shedd KB (2005) Tungsten recycling in the United States in 2000. US Geological Survey

Iguchi T, Ikegaya A (2008) Recycling of tungsten. In: Harada K, Nakamura T (eds) Technology of alternatives and recycling of rare metals. CMC Publishing Co, Ltd., Tokyo (in Japanese)

Nose K, Okabe TH (2011) Recycling technology of tungsten. Kinzoku 81:908–915 (in Japanese)

Itoh H (2013) Recent trend of rare metal recycling. J MMIJ 129:97–106 (in Japanese)

Bhosale SN, Mookherjee S, Pardeshi RM (1990) Current practices in tungsten extraction and recovery. High Temp Mater Processes 9:147–162

Ishida T, Itakura T, Moriguchi H, Ikegaya A (2012) Recycling technique for cemented carbide tools and development of tungsten-saving tools. SEI Tech Rev 181:33–39

Li KC, Wang CY (1955) Tungsten. Reinhold Publishing Corporation, New York, pp 175–176

Simon R (1981) DE3144295 (Germany patent)

Douglass AD, Reilly KT, Landmesser JE (1986) US4603043

Morishita M, Yamamoto H, Ikebe M, Yanagida H, Ueno T (2014) PCT. International patent, WO2014/045579

Yamamoto Y, Sasaya K, Fudo T, Nakano A, Yamanaka S, Iguchi T, Sato F, Ikegaya A (2010) PCT. International patent, WO2010/104009

Hayashi T, Sato F, Sasaya K, Ikegaya A (2016) Industrialization of tungsten recovering from used cemented carbide tools. SEI Tech Rev 189:8–14

Scott FH (1955) United Kingdom patent GB791925

Yasuda K, Nozaki F, Uehata R, Hagiwara R (2020) Oxidative dissolution of tungsten metal in Na2CO3 under Ar–O2–CO2 atmosphere. J Electrochem Soc 167:131501

Lohse M (1996) PCT. International patent, WO96/041768

Itakura T, Ikegaya A, Yamamoto Y (2016) Japanese patent JP6018958

Oishi T, Yaguchi M, Tanaka M (2013) Anodic dissolution of tungsten in a molten sodium hydroxide. J MMIJ 129:707–712

Oishi T, Yaguchi M (2017) Influence of partial pressure of water vapor on anodic dissolution of tungsten from super hard alloy tools in molten sodium hydroxide. Int J Refract Met Hard Mater 69:254–258

Oishi T, Yaguchi M (2018) Solubility of sodium tungstate in molten sodium hydroxide. Electrochemistry 86:61–65

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Oishi, T. (2022). Recycling of Tungsten by Molten Salt Process. In: Lazou, A., Daehn, K., Fleuriault, C., Gökelma, M., Olivetti, E., Meskers, C. (eds) REWAS 2022: Developing Tomorrow’s Technical Cycles (Volume I). The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-92563-5_7

Download citation

DOI: https://doi.org/10.1007/978-3-030-92563-5_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-92562-8

Online ISBN: 978-3-030-92563-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)