Abstract

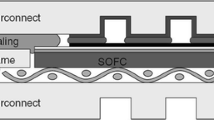

Sealants for high-temperature fuel cells and electrolyzers must exhibit special properties due to the high operating temperatures, the reactive atmospheres, and the electric voltage between the sealed interconnects. Various technological approaches and material classes are being pursued for this application. At the same time, there are also successful stack concepts that completely abandon the use of sealants. With regard to the materials in consideration, metallic brazing alloys and such based on mica compression seals play a marginal role and are only used in individual cases. Glass-ceramic seals are predominantly used and are therefore the focus of this section. A general insight into the topic of glass-ceramic sealants and their properties as well as strategies for their development will be provided. The content will help you better understand the behavior of complex glass-ceramic sealants. Important sections also embrace discussions on their degradation behavior under typical SOC conditions as well as their mechanical properties.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Abd El-Moneim A, Youssof IM, Abd El-Latif L (2006) Structural role of RO and Al2O3 in borate glasses. Acta Materialia 54:3811–3819

Batfalsky P, Haanappel VAC, Shemet V, Vinke IC, Steinbrech RW (2006) Chemical interaction between glass-ceramic sealants and interconnect steels in SOFC stacks. J Power Sour 155(2):128–137

Beatty CC (2005) Compliant glass-silver seals for SOFC applications electrochemical society proceedings 2005-07, pp 1949–1955

Bhattacharya S, Shashikala HD (2019) Effect of BaO on thermal and mechanical properties of alkaline earth borosilicate glasses with and without Al2O3. Physica B: Condensed Matter 571:76–86. https://doi.org/10.1016/j.physb.2019.06.065

Bram M, Reckers S, Drinovac P, Mnch J, Steinbrech RW, Buchkremer HP, Stver D (2004) Deformation behavior and leakage tests of alternate sealing materials for SOFS stacks. J Power Sour 138:111–119

Cela Greven B, Gross-Barsnick S, Koppitz T, Conradt R, Smeacetto F, Ventrella A, Ferraris M (2018) Torsional shear strength of novel glass-ceramic composite sealants for solid oxide fuel cell stacks Int. J Appl Ceram Technol 15(2):286–295. https://doi.org/10.1111/IJAC.12819

Chou YS, Stevenson JW (2004) Novel infiltrated Phlogopite mica compressive seals for solid oxide fuel cells. J Power Sour 135:72–78

Chou YS, Stevenson JW, Gow NR (2007a) Novel alkaline earth silicate sealing glass for SOFC Part I the effect of nickel oxide on the thermal and mechanical properties. J Power Sour 168:426–433

Chou YS, Stevenson JW, Gow NR (2007b) Novel alkaline earth silicate sealing glass for SOFC part II sealing and interfacial microstructure. J Power Sour 2007(170):395–400

Chou YS, Stevenson JW, Singh P (2007c) Novel refractory alkaline earth silicate sealing glassesfor planar solid oxide fuel cells. J Electrochem Soc 7(154):644–651

Chou Y, Stevenson JW, Singh P (2008a) Effect of pre-oxidation and environmental aging on the seal strength of a novel high-temperature solid oxide fuel cell (SOFC) sealing glass with metallic interconnect. J Power Sour 184(1):238–244. https://doi.org/10.1016/j.jpowsour.2008.06.020

Chou YS, Stevenson JW, Singh P (2008b) Effect of pre-oxidation and environmental aging on the seal strength of a novel high-temperature solid oxide fuel cell (SOFC) sealing glass with metallic interconnect. J Power Sour 184:238–244

Chou Y, Stevenson JW, Choi J-P (2010) Alkali effect on the electrical stability of a solid oxide fuel cell sealing glass. J Electrochem Soc 157(3):B348. https://doi.org/10.1149/1.3275744

Cleek GW, Babcock CI (1973) Properties of glasses in some ternary systems containing BaO and SiO2. National Bureau of Standards Monograph, vol 135

Corral EL, Gauntt BD, Loehman RE (2008) Properties of particle-filled glass composites used for sealing solid oxide fuel cells. In: Ceramic engineering and science proceedings band 28 (2008) 4, Seite 315–323 (9 Seiten, 11 Quellen), Westerville: American Ceramic Society (ACS)

Da Silva MJ, Bartolomé JF, Aza AH de, Mello-Castanho S (2016) Glass ceramic sealants belonging to BAS (BaO–Al2O3–SiO2) ternary system modified with B2O3 addition: a different approach to access the SOFC seal issue. J Europ Ceramic Soc 36(3):631–644. https://doi.org/10.1016/j.jeurceramsoc.2015.10.005

Donald IW (1993) Preparation, properties and chemistry of glass- and glass-ceramic-to-metal seals and coatings. J Mater Sci 28(11):2841–2886. https://doi.org/10.1007/BF00354689

Donald IW, Metcalfe BL, Gerrard LA (2008) Interfacial reactions in glass-ceramic-to-metal seals. J Am Ceram Soc 91(3):715–720

Donald IW, Mallison PM, Metcalfe BL, Gerrard LA, Fernie JA (2011) Recent developments in the preparation, characterization and applications of glass and glass-ceramic-to-metal- seals and coatings. J Mater Sci 46:1975–2000. https://doi.org/10.1007/s10853-010-5095-y

Eichler K, Solow G, Otschik P, Schaffrath W (2000) Degradation effects at sealing glasses for the SOFC European solid oxide fuel cell. Forum 4:899–906

Faidel D (2011) Laserstrahllöten mit glas-keramischen Zusatzwerkstoffen. Zugl.: Aachen, Techn. Hochs., Dissertion, Aachener Berichte Fügetechnik, 2012, 2. Shaker, Aachen

Fakouri Hasanabadi M, Faghihi-Sani MA, Kokabi AH, Malzbender J (2017) The analysis of torsional shear strength test of sealants for solid oxide fuel cells. Ceram Int 43(15):12546–12550. https://doi.org/10.1016/j.ceramint.2017.06.128

Fergus JW (2005) Sealants for solid oxide fuel cells. J Power Sour 147:46–57

Ferraris M, de La Pierre S, Sabato AG, Smeacetto F, Javed H, Walter C, Malzbender J (2020) Torsional shear strength behavior of advanced glass-ceramic sealants for SOFC/SOEC applications. J Eur Ceram Soc 40(12):4067–4075. https://doi.org/10.1016/j.jeurceramsoc.2020.04.034

Folgner C, Sauchuck V, Kusnezoff M, Michaelis A (2022) Influence of temperature and steam content on degradation of metallic interconnects in reducing atmosphere, pp 17–33. https://doi.org/10.1002/9781119474746.ch3

Frandsen HL, Ritucci I, Khajavi P, Talic B, Kiebach R, Hendriksen PV (2019) Enhancing the robustness of brittle solid oxide cell stack components. ECS Trans 91(1):2201–2211. https://doi.org/10.1149/09101.2201ecst

Frieser RG (1975) A review of solder glasses. Electrocomponent Sci Technol 2:163–199

Gent AN (1960) Theory of the parallel plate viscosimeter. British J Appl Phys 11:85–87

Goel A, Tulyaganov DU, Kharton VV, Yaremchenko AA (2009) Optimization of La2O3-containing diopside based glass-ceramic sealants for fuel cell applications. J Power Sour 189:1032–1043

Goel A, Pascual MJ, Ferreira JM (2010) Stable glass-ceramic sealants for solid oxide fuel cells: influence of Bi2O3 doping. Int J Hydrogen Energy 35(13):6911–6923. https://doi.org/10.1016/j.ijhydene.2010.04.106

Govindaraju N, Liu WN, Sun X, Singh P, Singh RN (2009) A modeling study on the thermomechanical behavior of glass-ceramic and self-healing glass seals at elevated temperatures. J Power Sour 190(2):476–484

Gross SM, Koppitz T, Reisgen U, Verlotski V, Conradt R (2005) Glass-ceramic Composites as a new sealing material for SOFCs. In: Electrochemical society proceedings 2005-07, pp 1924–1931

Gross SM, Federmann D, Remmel J, Pap M (2011) Reinforced composite sealants for solid oxide fuel cell applications. J Power Sour 196(17):7338–7342. https://doi.org/10.1016/j.jpowsour.2011.02.002

Gueguen Y, Houizot P, Célarié F, Chen M, Hirata A, Tan Y, Allix M, Chenu S, Roux-Langlois C, Rouxel T (2017) Structure and viscosity of phase-separated BaO-SiO2 glasses. J Amer Ceramic Soc 100(5):1982–1993. https://doi.org/10.1111/jace.14642

Guo Q, Feng T, Lance MJ, Unocic KA, Pantelides ST, Lara-Curzio E (2022) Evolution of the structure and chemical composition of the interface between multi-component silicate glasses and yttria-stabilized zirconia after 40,000 h exposure in air at 800 °C. J Europ Ceramic Soc 42(4):1576–1584. https://doi.org/10.1016/j.jeurceramsoc.2021.11.013

Haanappel VAC, Shemet V, Gross SM, Koppitz T, Menzler NH, Zahid M, Quadakkers WJ (2005) Behaviour of various-glass-ceramic sealants with ferritic steels under simulated SOFC stack conditions. J Power Sour 150:86–100

Heinrich JG, Aldinger F (2001) Ceramic materials and components for engines. Wiley-VCH, Weinheim, New York

Horita T, Sakai N, Kawada T, Yokokawa H, Dokiya M (1993) Reaction of SOFC components with sealing materials. Denki Kagaku1961. 61(7):760–762. https://doi.org/10.5796/electrochemistry.61.760

Hsueh C-H, Becher PF (1996) Residual thermal stresses in ceramic composites. Part i: with Ellipsoidal Inclusions Mater Sci Eng: A 212(1):22–28. https://doi.org/10.1016/0921-5093(96)10176-3

Javed H, Sabato AG, Mansourkiaei M, Ferrero D, Santarelli M, Herbrig K, Walter C, Smeacetto F (2020) Glass-ceramic sealants for SOEC: thermal characterization and electrical resistivity in dual atmosphere. Energies 13(14):3682.https://doi.org/10.3390/en13143682

Kilinc E, Hand RJ (2015) Mechanical properties of soda–lime–silica glasses with varying alkaline earth contents. J Non-Crystalline Solids 429:190–197. https://doi.org/10.1016/j.jnoncrysol.2015.08.013

Kolitsch U, Lengauer CL, Krause W, Bernhardt H-J, Medenbach O, Blaß G (2003) BaZrSi2O7, a new mineral from the Eifel volcanic area Germany. Mitt Österr Mineral Ges 148:199–200

Kuang K, Easler K (eds) (2007) Fuel cell electronics packaging. Springer, New York, NY

Kubaschewski O (2010) Iron-binary phase diagrams. Springer, Berlin, Heidelberg, New York, Verlag Stahleisen m.b.H.Dsseldorf, pp 172–175

Lahl N, Singh K, Singheiser L, Hilpert K, Bahadur D (2000) Crystallisation kinetics in AO-Al2O3-SiO2-B2O3 glasses (A = Ba, Ca, Mg). J Mater Sci 35(12):3089–3096

Lahl N, Bahadur D, Singh K, Singheiser L, Hilpert K (2002) Chemical interactions between aluminosilicate base sealants and the components on the anode side of solid oxide fuel cells. J Electrochem Soc 149. https://doi.org/10.1149/1.1467945

Lara C, Pascual MJ, Durn A (2004a) Glass-forming ability, sinterability and thermal properties in the systems RO-BaO-SiO2 (R = Mg, Zn). J Non-Crystalline Solids 348:149–155

Lara C, Pascual MJ, Prado MO, Durn A (2004b) Sintering of glasses in the system RO-Al2O3-BaO-SiO2 (R=Ca, Mg, Zn) studied by hot-stage microscopy. Solid State Ionics 170:201–208

Larsen PH, Poulsen FW, Berg RW (1999) The influence of SiO2 addition to 2MgO-Al2O3–3.3P2O5 glass. J Non-Crystalline Solids Band 244:Heft 1, Seite 16–24 (9 Seiten, 6 Bilder, 6 Tabellen, 21 Quellen) (1999)

Le S, Sun K, Zhang N, An M, Zhou D, Zhang J, Li D (2006) Novel compressive seals for solid oxide fuel cells. J Power Sour 161:901–906

Lejeune A-M, Richet P (1995) Rheology of crystal-bearing silicate melts: an experimental study at high viscosities. J Geophys Res 100(B3):4215–4229. https://doi.org/10.1029/94JB02985

Lessing PA (2007) A review of sealing technologies applicable to solid oxide electrolysis cells. J Mater Sci 42:3465–3476

Ley KL, Krumpelt M, Kumar R, Meiser JH, Bloom I (1996) Glass-ceramic sealants for solid oxide fuel cells: part I. Phys Propert J Mater Res 11(6):1489–1493. https://doi.org/10.1557/JMR.1996.0185

Li R, Tao M, Wang P, Yang J, Ma B, Chi B, Pu J (2021) Effect of interconnect pre-oxidation on high-temperature wettability and mechanical properties of glass seals in SOFC. J Am Ceram Soc 104(12):6172–6182. https://doi.org/10.1111/jace.18024

Li JH, Jiang YL, Wu JW, Pineault R, Gemmenn R, Liu XB (2010) Effect of electrical current on solid oxide fuel cells metallic interconnect oxidation in syngas SO. Int J Appl Ceram Technol 7(1):41–48. https://doi.org/10.1111/j.1744-7402.2009.02430.x

Lin C-K, Huang L-H, Chiang L-K, Chyou Y-P (2009) Thermal stress analysis of planar solid oxide fuel cell stacks: effects of sealing design. J Power Sour 192(2):515–524. https://doi.org/10.1016/j.jpowsour.2009.03.010

Lin C-K, Chen J-Y, Tian J-W, Chiang L-K, Wu S-H (2012) Joint strength of a solid oxide fuel cell glass–ceramic sealant with metallic interconnect. J Power Sour 205:307–317. https://doi.org/10.1016/j.jpowsour.2012.01.048

Liu WN, Sun X, Koeppel B, Stephens E, Khaleel MA (2011) Creep behavior of glass/ceramic sealant and its effect on long-term performance of solid oxide fuel cells. Int J Appl Ceram Technol 8(1):49–59. https://doi.org/10.1111/j.1744-7402.2009.02455.x

Mahapatra MK, Lu K (2010a) Effect of atmosphere on interconnect-seal glass interaction for solid oxide fuel/electrolyzer cells. J Am Ceram Soc 94(3):875–885

Mahapatra MK, Lu K (2010b) Glass-based seals for solid oxide fuel and electrolyzer cells—a review. Mater Sci Eng: R: Reports 67(5–6):65–85. https://doi.org/10.1016/j.mser.2009.12.002

Mahapatra MK, Lu K (2010) seal glass for solid oxide fuel cells. J Power Sour 195(21):7129–7139

Malzbender J, Steinbrech RW, Singheiser L (2003) Determination of the interfacial fracture energies of cathodes and glass ceramic sealants in a planar solid-oxide fuel cell design. J Mater Res 18(4):929–934. https://doi.org/10.1557/JMR.2003.0127

Malzbender J, Zhao Y (2012) Flexural strength and viscosity of glass ceramic sealants for solid oxide fuel cell stacks. Fuel Cells 12(1):47–53. https://doi.org/10.1002/fuce.201100116

Malzbender J, Toonder J den, Balkenende AR, With G de (2002) Measuring mechanical properties of coatings: a methodology applied to nano-particle-filled sol–gel coatings on glass. Mater Sci Eng: R: Reports 36(2–3):47–103. https://doi.org/10.1016/S0927-796X(01)00040-7

Malzbender J, Mnch J, Steinbrech RW, Koppitz T, Gross SM, Remmel J (2007) Symmetric shear test of glass-ceramic sealants at SOFC operation temperature. J Mater Sci 42:6297–6301

Meinhardt KD, Kim DS, Chou YS, Weil KS (2008) Synthesis and properties of a barium aluminosilicate solid oxide fuel cell glass-ceramic sealant. J Power Sour 182(2):188–196

Menzler NH, Sebold D, Gross SM, Shemet V, Zahid M (2005) Interaction of metallic SOFC interconnect and glass ceramic sealing under various atmospheric conditions at 800 °C. Electrochem Soc Proc 2005–07:1903–1912

Messler RW (2004) Joining of materials and structures: from pragmatic process to enabling technology. Elsevier, Amsterdam, Heidelberg

Miao X-Y, Rizvandi OB, Navasa M, Frandsen HL (2021) Modelling of local mechanical failures in solid oxide cell stacks. Appl Energy 293:116901.https://doi.org/10.1016/j.apenergy.2021.116901

Miletich R, Allan DR, Angel RJ (1997) The synthetic Cr2+ silicates BaCrSi4O10 and SrCrSi4O10: the missing links in the gillespite-type ABSi4O10 series. American Mineralogist 82(697)

Mita K, Ikeda T, Maeda M (2001) Phase diagram study of Fe-Zn intermetallics. J Phase Eqilibria 22(2):122–125

Moritz T, Schilm J, Rost A, Schwarzer E, Weingarten S, Scheithauer U, Wätzig K, Wagner D, Michaelis A (2019) Ceramic additive manufacturing methods applied to sintered glass components with novel properties CMT 1(2):111–119.https://doi.org/10.29272/cmt.2019.0008

Nielsen KA, Solvang M, Nielsen SBL, Dinesen AR, Beaff D, Larsen PH (2007) Glass composite seals for SOFC application. J Eur Ceram Soc 27(2–3):1817–1822

Niewolak L, Tietz F, Quadakkers WJ (2016) Interconnects. In: High-temperature solid oxide fuel cells for the 21st century, Elsevier, pp 195–254

Pascual MJ, Durán A (2001) Determination of the viscosity-temperature curve for glasses on the basis of fixed viscosity points determined by hot stage microscopy. Phys Chem Glasses 42(1):61–66

Pascual MJ, Guillet A, Durn A (2007) Optimization of glass-ceramic sealant compositions in the system MgO-BaO-SiO2 for solid oxide fuel cells (SOFC). J Power Sour 169:40–46

Prado MO, Zanotto ED (2002) Glass sintering with concurrent crystallization. C R Chim 5(11):773–786. https://doi.org/10.1016/S1631-0748(02)01447-9

Quadakkers WJ, Greiner H, Köck W (1994) Metals and alloys for high temperature SOFC applications. Europ Solid Oxide Fuel Cell Forum 535–541

Reddy AA, Tulyaganov DU, Pascual MJ, Kharton VV, Tsipis EV, Kolotygin VA, Ferreira JM (2013) Diopside–Ba disilicate glass–ceramic sealants for SOFCs: enhanced adhesion and thermal stability by Sr for Ca substitution. Int J Hydrogen Energy 38(7):3073–3086. https://doi.org/10.1016/j.ijhydene.2012.12.074

Ritucci I, Kiebach R, Talic B, Han L, Zielke P, Hendriksen PV, Frandsen HL (2019) Improving the interface adherence at sealings in solid oxide cell stacks. J Mater Res 34(07):1167–1178. https://doi.org/10.1557/jmr.2018.459

Rodríguez-López S, Haanappel V, Durán A, Muñoz F, Mather GC, Pascual MJ, Gross-Barsnick SM (2016) Glass–ceramic seals in the system MgO BaOB2O3SiO2 operating under simulated SOFC conditions. Int J Hydrogen Energy 41(34):15335–15345. https://doi.org/10.1016/j.ijhydene.2016.07.051

Rost A, Schilm J, Kusnezoff M (2009) Influence of electrical load on the stability of glass sealings. ECS Trans 25(2):1509–1518

Rost A, Schilm J, Kusnezoff M, Michaelis A (2012) Degradation of sealing glasses for SOFC under electrical load and dual atmosphere. J Ceramic Sci Technol 3(2):69–80. https://doi.org/10.4416/JCST2012-00002

Rost A (ed) (2013) Competence in ceramics: Entwicklung degradationsstabiler Glaslote für keramische Hochtemperaturbrennstoffzellen, vol 17. FRAUNHOFER VERLAG, Stuttgart

Sabato AG, Rost A, Schilm J, Kusnezoff M, Salvo M, Chrysanthou A, Smeacetto F (2019) Effect of electric load and dual atmosphere on the properties of an alkali containing diopside-based glass sealant for solid oxide cells. J Power Sour 415:15–24. https://doi.org/10.1016/j.jpowsour.2019.01.051

Sarkardeh FB, Meschke F, Hilpert K, Singheiser L (eds) (1999) Berichte des Forschungszentrums Jülich: Stabilität und Kompatibilität des keramischen Interkonnektors der Hochtemperatur-Brennstoffzelle SOFC, Jülich

Sauchuck V, Kusnezoff M, Trofimenko N, Megel S, Baldus H-P, Reinert A (2008) Development of effective protective materials for SOFC metallic interconnects. In: 8th European solid oxide fuel cell forum, vol 09

Sauchuck V, Trofimenko N, Megel S, Rothe S, Schilm J, Andritschky M, Hiller M, Goebel C, Froitzheim J, Kusnezoff M (2020) Application of composite coatings as protection/contacting layers for metallic highchromium-content SOFC interconnect material. In: 14th European SOFC & SOE Forum, pp 601–611

Schilling C, Roosen A (2012) Fügen von keramischen Komponenten der Hochtemperatur-Brennstoffzellen mittels Glas-und Glaskeramikloten. Friedrich Alexander University Erlangen-Nuremberg, PdD

Schilm J, Rost A, Kusnezoff M, Michaelis A (2010) Sealing glasses for SOFC—degradation behaviour. In: Advances in solid oxide fuel cells V, Wiley, Ltd, pp 183–193

Schilm J, Rost A, Poenicke A, Kusnezoff M, Michaelis A (2012) Ceramic integration technologies for solid oxide fuel cells. Int J Appl Ceram Technol 9(4):688–699. https://doi.org/10.1111/j.1744-7402.2012.02789.x

Schilm J, Rost A, Kusnezoff M, Megel S, Michaelis A (2018) Glass ceramics sealants for SOFC interconnects based on a high chromium sinter alloy Int. J Appl Ceram Technol 15(2):239–254. https://doi.org/10.1111/ijac.12811

Scholze H (1962) Der Einfluss Von Viskositaet Und Oberflchenspannung Auf Erhitzungsmikroskopische Messungen an Glaesern Berichte Der Deutschen Keramischen Gesellschaft 59:63–68

Scholze H (1977) Glas, natur, struktur und eigenschaften, Zweite, neubearbeitete. Springer, Berlin Heidelberg New York

Selçuk A, Atkinson A (1997) Elastic properties of ceramic oxides used in solid oxide fuel cells (SOFC). J Europ Ceramic Soc 17(12):1523–1532. https://doi.org/10.1016/S0955-2219(96)00247-6

Selsing J (1961) Internal stresses in ceramics. J Am Ceram Soc 44(8):419. https://doi.org/10.1111/j.1151-2916.1961.tb15475.x

Serbena FC, Soares VO, Peitl O, Pinto H, Muccillo R, Zanotto ED (2011) Internal residual stresses in sintered and commercial low expansion Li2O-Al2O3-SiO2 glass-ceramics. J Amer Ceramic Soc 94(4):1206–1214. https://doi.org/10.1111/j.1551-2916.2010.04220.x

Shabanova GN, Taranenkova VV, Korogodskaya AN, Khristich EV (2003) Structure of the BaO-Al2O3-SiO2 system (a review). Glass and Ceramics 60(1–2):43–46

Shelby JE (1979) Effect of morphology on the properties of alkaline earth silicate glasses. J Appl Phys 50(12):8010–8015. https://doi.org/10.1063/1.325986

Singh K, Walia T (2021) Review on silicate and borosilicate-based glass sealants and their interaction with components of solid oxide fuel cell. Int J Energy Res 45(15):20559–20582. https://doi.org/10.1002/er.7161

Smeacetto F, Salvo M, Ferraris M, Casalegno V, Asinari P, Chrysanthou A (2008a5a) Characterization and performance of glass-ceramic sealant to join metallic interconnects to YSZ and anode-supported-electrolyte in planar SOFCs. J Europ Ceramic Soc 28:2521–2527

Smeacetto F, Salvo M, Ferraris M, Casalegno V, Asinari P, Chrysanthou A (2008b) Characterization and performance of glass–ceramic sealant to join metallic interconnects to YSZ and anode-supported-electrolyte in planar SOFCs. J Europ Ceramic Soc 28(13):2521–2527. https://doi.org/10.1016/j.jeurceramsoc.2008.03.035

Smeacetto F, Salvo M, Ferraris M, Casalegno V, Asinari P (2008c) Glass and composite seals for the joining of YSZ to metallic interconnect in solid oxide fuel cells. J Eur Ceram Soc 28(3):611–616

Sohn S-B, Choi S-Y, Kim G-H, Song H-S, Kim G-D (2002) Stable sealing glass for planar solid oxide fuel cell. J Non-Cryst Solids 297(2–3):103–112. https://doi.org/10.1016/S0022-3093(01)01042-0

Sohn SB, Choi SY, Kim GH, Song HS, Kim GD (2004) Suitable glass-ceramic sealant for planar solid-oxide fuel cells. J Am Ceram Soc 87(2):254–260

Sumi H, Shimada H, Yamaguchi T, Fujishiro Y, Awano M (2019) Development of portable solid oxide fuel cell system driven by hydrocarbon and alcohol fuels. In: Salem J, Koch D, Mechnich P, Kusnezoff M, Bansal N, LaSalvia J, Balaya P, Fu Z, Ohji T (eds) Proceeding of the 42nd international conference on advanced ceramics and composites. Ceramic engineering and science proceedings, Wiley, Inc, Hoboken, NJ, USA, pp 159–163

Sun T, Xiao H, Guo W, Hong X (2010) Effect of Al2O3 content on BaO–Al2O3–B2O3–SiO2 glass sealant for solid oxide fuel cell. Ceramics Int 36(2):821–826. https://doi.org/10.1016/j.ceramint.2009.09.045

Theerapapvisetpong A, Jiemsirilers S, Thavorniti P, Conradt R (2011) Barium-free glass-ceramic sealants from the system CaO-MgO-B2O3-Al2O3-SiO2 for application in the SOFC. MSF 695:1–4. https://doi.org/10.4028/www.scientific.net/MSF.695.1

Thomas RH (1950) Phase equilibrium in a portion of the ternary system Ba OA-I2,O3,-SiO2. J Amer Ceramic Soc 33(2):35–44. https://doi.org/10.1111/j.1151-2916.1950.tb14163.x

Venskutonis A, Brandner M, Kraussler W, Sigl L (2009) High volume fabrication of ready-to-stack components for planar SOFC concepts ECS. Trans 25(2):1353–1359. https://doi.org/10.1149/1.3205664

Wanko E, Gross SM, Koppitz T, Remmel J, Reisgen U, Wilsmann W, Conradt R (eds) (2007) Glaskeramische Materialien des Systems BaO-MgO-SiO2 zum Lten der Hochtemperatur-Brennstoffzelle (SOFC). In: Disserion. Brazing, High Temperature Brazing and Diffusion Welding, Aachen

Wanko E, Gross SM, Remmel J, Reisgen U, Conradt R (2008a) Composits from the system BaO-MgO-SiO2 as sealing material for the high temperature fuel cell (SOFC) DVS-Berichte(250), 474–477 (2008a)

Wanko E, Gross SM, Remmel J, Reisgen U, Conradt R (eds) (2008b) Verbundwerkstoffe aus dem System BaO-MgO-SiO2als Fügematerial für die Hochtemperaturbrennstoffzelle (SOFC). In: Dissertion Groe Schweitechnische Tagung, Dresden

Weil KS, Deibler JE, Hardy JS, Kim DS, Xia GG, Chick LA, Coyle CA (2004) Rupture testing as a tool for developing planar solid oxide fuel cell seals. J Mater Eng Perform 13(3):316–326. https://doi.org/10.1361/10599490419306

Wenning NL, Xin S, Brian K, Mohammad K (2010) Experimental study of the aging and self-healing of the glass/ceramic sealant used in SOFCs SO. Int J Appl Ceram Technol 7(1):22–29. https://doi.org/10.1111/j.1744-7402.2009.02417.x

Wiener F, Bram M, Sebold D (2007) Chemical interaction between Crofer 22 APU and mica-based gaskets under simulated SOFC conditions. J Mater Sci 42(8):2643–2651

Yang Z, Meinhardt KD, Stevenson JW (2003) Chemical compatibility of barium-calcium-aluminosilicate-based sealing glasses with the ferritic stainless steel interconnect in SOFCs. J Electrochem Soc 150(8):1095–1101. https://doi.org/10.1149/1.1590325

Yang Z, Xia GG, Meinhardt J, Weil KS, Stevenson JW (2005) Glass sealing in planar SOFC stacks and chemical stability of seal interfaces. Ceram Trans 158:135–146

Yeong SC, Stevenson JW, Chick LA (2003) Novel compressive mica seals with metallic interlayers for solid oxide fuel cell applications. J Am Ceram Soc 86(6):1003–1007

Zhang T, Fahrenholtz WG, Reis ST, Brow RK (2008) Borate volatility from SOFC sealing glasses. J Am Ceram Soc 91(8):2564–2569. https://doi.org/10.1111/j.1551-2916.2008.02479.x

Zhao Y, Malzbender J, Gross SM (2011) The effect of room temperature and high temperature exposure on the elastic modulus, hardness and fracture toughness of glass ceramic sealants for solid oxide fuel cells. J Europ Ceramic Soc 31(4):541–548. https://doi.org/10.1016/j.jeurceramsoc.2010.10.032

Zhang T, Brow RK, Fahrenholtz WG, Reis ST (2012) Chromate formation at the interface between a solid oxide fuel cell sealing glass and interconnect alloy. J Power Sour 205:301–306

Zhenguo Y, Stevenson JW, Meinhardt KD (2003) Chemical interactions of barium-calcium-aluminosilicate-based sealing glasses with oxidation resistant alloys. Solid State Ionics 160:213–225

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Schilm, J., Kusnezoff, M., Rost, A. (2023). Glass Ceramic Sealants for Solid Oxide Cells. In: Laguna-Bercero, M.A. (eds) High Temperature Electrolysis. Lecture Notes in Energy, vol 95. Springer, Cham. https://doi.org/10.1007/978-3-031-22508-6_7

Download citation

DOI: https://doi.org/10.1007/978-3-031-22508-6_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-22507-9

Online ISBN: 978-3-031-22508-6

eBook Packages: EnergyEnergy (R0)