Abstract

This paper considers the sustainability of geosynthetics-based solutions to mitigate landslide risks. The different types of geosynthetics are briefly described, along with their functions and applications relevant to landslides, emphasizing reinforcement. The paper identifies the sustainability factors to consider when applying geosynthetics for these purposes. The paper then presents an overview based on existing literature to illustrate how geosynthetics typically outperform traditional methods across a range of sustainability criteria across the entire life cycle. The paper shows lastly how the value integrated model for sustainable evaluations (MIVES) tool can be applied to evaluate and compare alternative methods for remediation of landslides and recommends further studies using this tool.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Landslides have occurred since time immemorial, even without any land transformation generated by human actions. They can occur worldwide, with little distinction across geographical locations, and represent one of the most common geological events.

Historically, different construction solutions have been considered with the aim of avoiding ground displacements, especially where there is risk to life or where infrastructure, buildings, or service installations are vulnerable to damage. It is essential to choose the appropriate solution based on a solid understanding of the causes of landslides. Among the natural causes, the most frequent are rainwater infiltration, rising groundwater levels, loss of vegetated surface, erosion, and weathering.

Human land use and related ground transformation often increase the potential for landslides, for example, as a consequence of construction, earthworks, and urbanization—i.e., modification of previously stable geometries and/or loading conditions. Other significant factors include deforestation (change of the previous surface scenario that may include deep-rooted vegetation removal), blasting and mining, and agricultural and forestry activities.

Appropriate preventative measures can be active or passive, depending on the specific factors. Active interventions may include direct ground modifications or measures to rectify previous potentially unstable scenarios by modifying the geometry of the land or strengthening the ground. Examples of passive approaches include mechanical protective measures, drainage, filtration, and separation.

Geosynthetics are durable polymers that provide high performance, and they often contribute to making infrastructures more sustainable in many aspects. Nowadays, polymeric materials are used routinely for soil reinforcement and stabilization, barrier systems and hydraulic drainage within the civil engineering framework. Fibrous filter fabric products were already used in ancient times to improve the mechanical performance of soil, using natural fabrics or vegetation. But, in the final third of the twentieth century, more stable and durable products were available, following the advent of polymeric materials. As the technology advanced, its effectiveness increased significantly, and previously unknown or unconsidered applications became viable.

The list of the most commonly used geosynthetic products currently available is extensive. It includes geotextiles, geogrids, geonets, geomembranes, geocells, and geocomposites. These products consist of diverse materials, typically polyamide, polyester, polyethylene, polypropylene, polyvinylchloride, ethylene and copolymer. They take various forms, usually sheets, grids, cells, or strips. This diversity of material and form leads to performance that is well adapted to the specific needs of the required function.

2 Geosynthetics for Landslide Prevention

Within the many civil engineering applications where geosynthetics play a fundamental role, their use in landslide stabilization projects is not new. The main related functions for landslide stability purposes are filtration, drainage, protection and reinforcement. Geosynthetics demonstrate several significant mechanical/functional/technical advantages.

Engineers can prevent landslides in various ways using geosynthetics:

-

using geotextiles and geomembranes to perform barrier function and/or filter function, which prevents the effects of water seepage;

-

using high strength geosynthetics to reinforce the soil, thus making stable even for very steep slopes;

-

using geomats and geocells for hold topsoil in place, thus preventing slippage;

-

using geocomposite drains to allow excess rainwater to disperse safely, without washing the soil away; and/or

-

applying geosynthetics for erosion control to the surfaces of slopes to encourage the growth of new vegetation and provide anchorage to the root structures, thereby increasing their erosion resistance under significant hydraulic stresses, further stabilizing slopes through natural means.

For landslide mitigation, geosynthetics are often utilized to provide tensile strength and added stiffness to the soil, which is basically strong in compression, to achieve a safe level. Geosynthetic reinforcements combine high tensile strength (up to 1000 kN/m in some products) with limited tensile creep, improved interaction with the surrounding soil material, and resistance to chemical/biological degradation and environmental ageing.

Since 1980 geosynthetics, and particularly geogrids, have been extensively used for the construction of Reinforced Soil Structures (RSSs), and in many landslide stabilization projects, for slopes as high as 60 m (Cambiaghi and Rimoldi 1991; Cazzuffi et al. 1995; Coluzzi et al. 1996; Coluzzi et al. 1996; Coluzzi et al. 1997; Dikran and Rimoldi 1994; Manni and Rimoldi, 2006; Rimoldi 1996; Rimoldi and Ricciuti 1992; Rimoldi and Scotto 2012).

RSSs have been designed and built even in highly seismic areas (Rimoldi 2018) using cohesive/ marginal fills (Giroud et al. 2014).

Layers of geosynthetic reinforcement are used to stabilize slopes against potential deep-seated failure using horizontal layers of primary reinforcement. The reinforced slope may be part of slope reinstatement and/or used to strengthen the sides of earth fill embankments.

The reinforcement layers allow slope faces to be constructed at steeper angles than the unreinforced slope. It may be necessary to stabilize the face of the slope (particularly during fill placement and compaction) by using relatively short and more tightly spaced secondary reinforcement and/or wrapping the reinforcement layers at the face. In most cases, the face of the slope must be protected against erosion. An interceptor drain may be required to eliminate seepage forces in the reinforced soil zone. Figure 1 shows the scheme of a reinforced soil slope, and Fig. 2 shows an example of a remediated slope with a reinforced slope structure.

Recently, Rimoldi et al. (2021) reported on geosynthetic reinforced soil structures for slope stabilization and landslide rehabilitation in Asia, including slope reinforcement and drainage (Fig. 3). In most applications, geosynthetics usually offer lower production costs than traditional solutions. Geosynthetics can be shown to be the best products used in landslide rehabilitation and natural disaster reconstruction through life cycle cost analysis. In fact, there are several advantages when using geosynthetics: space savings; avoidance of costly ‘remove and replace’ methods; possible use of locally available lower quality backfill materials; low maintenance due to long life cycle; lower time and labour costs, because geosynthetics are easy to install, use less backfill material and require no special equipment; increased reliability of designed solutions thanks to geosynthetics’ guaranteed mechanical and hydraulic properties.

Geosynthetic reinforced soil structures for slope stabilization and landslide rehabilitation in Asia (from Rimoldi et al. 2021): a reinforced soil structure along the river Myittha in Myanmar, as a remedial work of an existing collapsed concrete masonry wall, b installation of gravel layer wrapped with nonwoven geotextile as drainage material, c rainwater runoff triggered a slope collapse, and d installation of geosynthetic reinforcements and view of the completed slope remediation

3 Sustainability

As an integral part of civil engineering design decision-making, sustainability criteria are becoming more common (e.g., Aguado et al. 2012; MacAskill and Guthrie 2013), including in geotechnical engineering projects (Basu et al. 2014; Holt et al. 2010). Sustainability and sustainable development include the capacity to carry out an activity (such as manufacturing or constructing a product or structure) with minimal or no impact (BSI 2012; Josa and Alavedra 2006; WCED 1987). However, sustainability is more broadly defined as satisfying three sets of requirements or pillars based on environmental, economic and societal/ technical/ functional criteria (Afnor Group 2012; ISO 2019). Sustainability objectives can vary between project types and within different categories due to differences in costs of materials, construction, maintenance, environmental and societal impacts, etc.

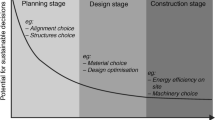

Sustainable design involves finding a satisfactory balance between these competing objectives (Basu and Puppala 2015; Josa and Alavedra 2006; Josa et al. 2008). A key feature of sustainable design is a structure or project lifetime ‘cradle-to-grave’ perspective, although ‘cradle-to-operation’ or ‘cradle-to-gate’ are also common (ISO 2006a, b). In slope stability, lifetime use is considered in six stages comprising (1) extraction and processing of raw materials, (2) production of materials required for each alternative approach (including the extraction and treatment of aggregates, specific geosynthetic products production, and all/other products/processes involved, etc.), (3) construction/execution/installation of the alternative and all related/involved works including necessary controls/checking tasks during construction, (4) maintenance involved in the whole service life, including eventual final stage, (5) demolition up to achieving (6) end-of-life stage of the solution. All these tasks are directly related to energy consumption both for direct execution and indirectly, e.g., transport. Obviously, this lifetime has to be the same for all alternatives under comparison, which is included in the definition of the functional unit, fixed between them.

Therefore, sustainability is understood and standardized in the context of our global systems to encompass environmental, economic and social impacts, where the needs of the present generation are met without compromising those of future generations. From this sustainability point of view, geosynthetics have proven themselves as suitable solutions in many civil engineering applications. Often, they represent the best option across multiple sustainability factors, particularly for landslide stability purposes. Whether in landslide or other applications, when compared with conventional approaches, geosynthetics-based solutions have demonstrated reduced material use and lower costs for materials, construction and maintenance works.

In general terms, economically, at the construction level of slope stabilization, different studies have proven that a construction solution that opts for geocomposites is much more economical and efficient. The use of geosynthetics may reduce or even eliminate waste deposits. Furthermore, geosynthetics can also serve as reinforcing and/or drainage materials to accelerate the consolidation of soft subgrades, thereby reducing execution times, transportation, and general construction-related costs.

Geosynthetics also deliver superior environmental performance in terms of a smaller carbon footprint and effective climate mitigation and adaptation. Material displacements are considerably reduced, and the tools and equipment used for installation are much simpler than traditional methods. Transportation is also much easier, and there is no need for highly qualified personnel to perform installation and construction. Compared with conventional options, significant savings are typically obtained (Christopher 2014).

Geosynthetics also bring significant social, technical and functional benefits in comparison with other foundation-stabilization methods such as dewatering, excavation, and replacement with certain granular materials or chemical stabilization. Compared with traditional drainage methods (i.e., sand and gravel), a key advantage is that geosynthetics-based solutions significantly reduce the required thickness of aggregate layers compared with conventional solutions. Also, geosynthetic products typically work better than the geotechnical materials they replace and the performance improvement is gained by using manufactured materials with fully known properties.

3.1 Sustainability Assessment: MIVES Methodology for the Case of Slope Stability Remediation Alternatives. General Approach

A sustainability assessment model should be based on value theory and multi-attribute assumptions. For slope stabilization performances, a value integrated model for sustainability evaluations (MIVES) methodology may be used (Josa et al. 2008), as has already been done for other civil engineering applications. Damians et al. (2018) present a clear and direct application for retaining wall structures, which can be used here as a reference for slope stability applications.

The MIVES method (hosted in free software available at: https://deca.upc.edu/es/proyectos/mives/descargas) can be used for quantitative sustainability assessment of any defined functional unit for which inputs and outputs can be related for each requirement level or pillar category by using multicriteria analyses.

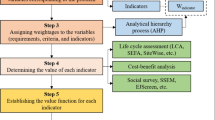

As already stated, a proper definition of the functional unit is crucial for a correct comparison between alternative solutions (in this case, for example, according to different measures/actions to remediate unstable slopes, affecting the same extension area, etc.). According to the functional unit, the full inventory of materials and actions related to each case study analysis is required (indicator items list). The sustainability assessment methodology and related outcomes using the MIVES approach can be understood from the flow chart in Fig. 4, where the requirements tree is defined by a hierarchical process. Sustainability requirements refer to environmental, economic and societal/ technical/ functional pillars (the basic/standardized pillar categories defining sustainability; ISO 2019). Each category is defined by criteria with three or more quantifiable indicators. Each multicriteria analysis ends with a single numerical score (Vfinal) suitable for objective decision-making between the different project alternatives under consideration. The global process of assigning values and weighting to each indicator—criteria—requirement level to arrive at a final MIVES score (Vfinal) is shown below the flow chart in Fig. 4 and explained.

Sustainability assessment flow chart or requirements tree proposal for landslide applications (modified from Damians et al. 2018)

3.2 Sustainability Requirements Definition

For slope stability purposes, as typically done in many other areas, the economic pillar can focus on project costs. These costs accrue from the manufacturing and transportation of construction materials, anticipated material losses, on-site fabrication of structural remediation components, including labour and the like. For cradle-to-grave sustainability assessment, these costs include operation but also maintenance and, if included in the functional unit lifetime definition, final dismantling and disposal of materials.

Cost variability is common in civil and construction engineering projects (depending on the project’s specifics, site of the works, types of suppliers, materials/specifications, etc.). Probabilistic cost analysis is recommended. While cost can be finally grouped as a single indicator, it may also be split with regard to costing types (in such cases, probabilistic analysis may be applied to some indicators only).

The environmental pillar focuses on environmental impacts and is most often addressed through a life cycle assessment (LCA) approach. Fraser et al. (2012), Heerten (2012), Stucki et al. (2011), and Damians et al. (2017) present examples where LCA approaches were applied in studies of different geosynthetic applications to civil engineering. An LCA should ideally consider all possible environmental impacts of any construction process and materials used in the project works (ISO 2006b). Midpoint (pM) indicators (e.g., tonnes carbon dioxide equivalent (tCO2e)) are used to identify intermediate effects of pollutants, and damage models are used to compute endpoint (Ep) indicators, which are combined to give a ‘final-effects’ LCA endpoint score. Quantification of environmental impacts is well established in the scientific literature, and databases are available. Damage categories can be weighted based on socio-political factors and uncertainty in calculations when computing the final (dimensionless) endpoint score for project alternatives in LCA. This score can then be used for decision-making based on environmental impacts alone (Bare et al. 2000). Figure 5 presents the relationship between the life cycle impacts, midpoint indicators and endpoint indicators for nine categories. Different environmental midpoint impact categories can be included according to the specific alternatives analysed, and site-application effects representation for specific slope stability purposes.

Relationship between life cycle impacts, midpoint and endpoint indicators, ReCiPe method (modified from Goedkoop et al. 2008)

The societal/technical/functional pillar captures requirements related to issues such as aesthetics, safety, ease of design and constructability, among many other considerations including, for example, technical issues/considerations regarding the specific products available and/or to apply for slope stability purposes. These issues vary according to subjective importance and assessment. A practical strategy to quantify these issues is to develop a survey tool that representative agents, stakeholders and suitably qualified professionals can fill out. The results can be weighted using analytic hierarchy process techniques (Saaty 2008).

4 MIVES in Brief

Multi-attribute utility theory and value analysis provide a rigorous framework through a process of hierarchy, evaluation, valuation, weighting and aggregation. Once the requirements/ criteria/ indicators are defined by hierarchy (1st stage; see requirements tree in Fig. 4), all indicators (including the whole inventory of materials and processes involved as indicator items) must be properly defined and categorized by evaluation (2nd stage). The inventory of materials and processes have to be determined for the specific functional unit definition, which shall logically be the same for all alternatives selected for the sustainability assessment. After that, it is necessary to compare the resulting quantifications between all indicators from the three pillars through due valuation (3rd stage).

The definition of the decision-making options (or stakeholder scenarios) and related sensitivities is done by weighting (4th stage) to the requirements or pillars (Wrequirement). It should be noted that the weighting process is applied to all indicators (Windicator) and criteria (Wcriterion) and/or in all possible layers/sub-criteria—if there are—within the same requirement level. However, in some cases, a particular indicator/criterion’s weighting may not be influenced by the stakeholder scenario and must be assumed separately/independently as per technical criteria.

Finally, summation of values and linked weights for each step within the flow chart (requirements tree) shall be done by aggregation (5th stage), achieving the final MIVES result/score (Vfinal) and obtaining the best alternative in terms of sustainability. Thus, each option is assessed independently, with the best solution identified as the option with the best aggregate score.

An important feature of the MIVES sustainability assessment model is that the strength of each option is influenced by the strength of the competing options during the scoring calculations for each of the three pillar categories or requirements.

5 Evaluation Process: The Value Functions

Evaluation is usually difficult because indicators are often not directly comparable. This is what happens, for example, when safety factors (non-dimensional) are compared with related financial costs, or if the execution/installation time of specific construction actions for a particular alternative is balanced against tons of CO2 generated. Even when using the same quantification unit, in many cases, it is difficult to compare indicators (for example, when comparing costs derived from different stages/concepts/processes involved in the same product or alternative). Accordingly, it is necessary to translate all the indicators into a common/single one to allow comparison. This transformation is done by the value functions, which can be defined by different trends, adopting different forms (i.e., linear, concave, convex, sigmoidal, etc.), as appropriate. Examples of value functions are shown in Fig. 6. Value functions can also be discrete or non-continuous. Value functions are used as converters from original indicator quantifications (X-axis) to dimensionless indicator values (Vindicator) between 0 and 1 (y-axis; see Fig. 6). While a value function trend should be established (e.g., higher value for: lower cost, lower environmental impacts, better protection, better functionality/ robustness/ resilience, lower labour, and technical-specific requirements, lower land used, etc.), the shape of this function may be difficult to define.

Different types and tendencies of value functions: a concave, b convex, c linear, and d S-shape (modified from Alarcón et al. 2011)

A good way to properly define function shape is to begin by identifying the real maximum/minimum indicator scores (quantification) for inclusion. It is not necessary to define maxima and minima according to the values suggested by each alternative solution, as objective limits may have been set independently, e.g., security factors must be met regardless of cost or idealized values—such as net-zero carbon—may have been set to force alternatives to achieve them.

Once minima and maxima are defined, it is necessary to identify the desired approach for alternatives that are close to these limits. How much do we want to penalize for being close to the unwanted limit? How convenient is it to segregate alternative solutions close to the set boundaries? For economic impacts, lower costs to low probable limits (very efficient use of materials and no losses of any kind) can be established for the highest possible value (i.e., Veconomic-indicator = 1). For environmental impacts, idealized limits can be established, although none of the analysed solutions is required to achieve the higher value limit with Venvironmental-indicator = 1). Although there are different ways to define the value functions, Eq. (1) is proposed below (after Alarcón et al. 2011) and has been already used in many civil engineering applications (Aguado et al. 2012; Viñolas 2011; Damians et al. 2017; Pujadas et al. 2017; Josa et al. 2020; among others).

where:

- Vi:

-

is the value of the indicator being evaluated.

- Smin:

-

is the point of minimum satisfaction, with a value of 0.

- X:

-

is the abscissa that generates a value equal to Vindicator.

- P:

-

defines approximately the shape of the curve: concave, convex, linear or S-shaped (see Fig. 6). If P < 1 the curve is concave; if P > 1 the curve is convex or S-shaped, if P = 1 it is linear.

- C:

-

is a parameter that approximately defines the x-value of the point of inflexion for curves with P > 1.

- K:

-

is a parameter that approximately defines the y-value at the point C.

- B:

-

is a factor that allows the function to remain within the range from 0 to 1. It is assumed that the highest level of satisfaction has a value of 1. This factor is determined by Eq. (2).

where:

- S max :

-

is the point of maximum satisfaction, with a value of 1.

6 Conclusion

Multiple technological advances have allowed progress in many fields of civil engineering, enabling significant reductions in atmospheric CO2 emissions, cost savings for personnel and construction material, and enhanced effectiveness compared with traditional solutions.

Many studies demonstrate that geosynthetic materials significantly contribute to preventing, avoiding, or reducing the potentially catastrophic effects caused by land changes and soil erosion. Their use not only saves time and money in installation but can also save lives. Sustainability assessment methods that account for environmental impact, cost and societal/functional considerations are becoming an important civil engineering tool for selecting the best option among multiple solutions performing the same function.

A suitable methodology to assess different alternatives for remediation of slope instability is available through the MIVES tool and presented in this study. Other landslide mitigation application cases should be analysed, applying specific protocols or particular model features based on the proposed methodology. Further developments and examples of practical use of the MIVES are expected in the future.

References

AFNOR Group (2012) CEN/TC 350: sustainability of construction works. AFNOR Group

Aguado A, del Caño A, de la Cruz MP, Gómez D, Josa A (2012) Sustainability assessment of concrete structures within the Spanish structural concrete code. ASCE J Constr Eng Manage 138(2):268–276

Alarcon B, Aguado A, Manga R, Josa A (2011) A value function for assessing sustainability: application to industrial buildings. Sustainability 3(1):35–50

Bare JC, Hofstetter P, Pennington D, Udo de Hades HA (2000) Midpoints versus endpoints: the sacrifices and benefits. Int J Life Cycle Ass 5(6):319–326

Basu D, Misra A, Puppala AJ (2014) Sustainability and geotechnical engineering: perspectives and review. Can Geotech J 52(1):96–113

BSI (2012) BS EN 15804: sustainability of construction works—environmental product declarations—core rules for the product category of construction products. BSI

Cambiaghi A, Rimoldi P (1991) The use of geogrids in landslide control works: a case history from Valtellina (Northern Italy). In: Proceedings of international conference on slope stability engineering—developments and applications. Isle of Wight

Cazzuffi D, Giusti G, Rimoldi P (1995) Lessons learned from the loss of performance of a 47m high geotextile reinforced slope subsequently replaced with a geogrid reinforced slope. In: Giroud JP, Soderman K L (eds) Geosynthetics: lessons learned from Failures Editors. IFAI, Roseville

Christopher BR (2014) Costs savings by using construction methods with geosynthetics. In: Proceedings 10ICG—10th international conference on geosynthetics, 21–25 Sept., Berlin

Coluzzi E, Montanelli F, Recalcati P, Rimoldi P, Zinesi M (1997) Preliminary results from an instrumented geogrid reinforced slope for the stabilisation of the Montone hill in central Italy. In: Proceedings of international conference on mechanical stabilized backfill. Denver, Colorado

Coluzzi E, Recalcati P, Rimoldi P, (1996) Landslide repairs with green faced reinforced walls. In: Proceedings International seminar on environmental geotechnology with geosynthetics—INTSEMEGG ‘96. New Delhi

Damians IP, Bathurst RJ, Adroguer E, Josa A, Lloret A (2018) Sustainability assessment of earth retaining wall structures. ICE Env Geotech 5(4):187–203

Damians IP, Bathurst RJ, Adroguer E, Josa A, Lloret A (2017) Environmental assessment of earth retaining wall structures. ICE Environ Geotech 4(6)

Dikran S, Rimoldi P (1994) The use of geogrids to increase the stability of slopes. In: Proceedings of international conference on landslides, slope stability & the safety of infra-structures. Kuala Lumpur

Fraser I, Elsing A, Stucki M et al (2012) Comparative life cycle assessment of geosynthetics versus conventional construction materials, a study on behalf of the E.A.G.M., case 4, soil retaining wall. In: Proceedings of the 5th European geosynthetics congress, Valencia, vol 4, pp 218–222

Giroud J P, Naughton P J, Rimoldi P, Scotto M (2014) Design of reinforced slopes and walls with low-permeability fills using draining geogrids. In: Proceedings 10ICG—10th international conference on geosynthetics. Berlin

Goedkoop M, Heijungs R, Huijbregts M et al (2008) ReCiPe 2008. A life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level, report I: characterisation. Den Haag. See http://www.lcia-recipe.net/

Heerten G (2012) Reduction of climate-damaging gases in geotechnical engineering practice using geosynthetics. Geotext Geomem 30:43–49

Holt DG, Jefferson I, Braithwaite PA, Chapman DN (2010) Embedding sustainability into geotechnics—part A: methodology. Proc Inst Civil Eng Eng Sustain 163(3):127–135

ISO (International Organization for Standardization) (2006a) ISO 14040: Environmental management—life cycle assessment—principles and framework. ISO, Geneva

ISO (2006b) ISO 14044: environmental management—life cycle assessment—requirements and guidelines. ISO, Geneva

ISO (2019) ISO 21931: sustainability in buildings and civil engineering works—framework for methods of assessment of the environmental, social and economic performance of construction works as a basis for sustainability assessment—part 2: civil engineering works. ISO, Geneva

Josa A, Alavedra P (2006) El concepto de sostenibilidad. In: Losada R, Rojí E, Cuadrado J (eds) La Medida de la Sostenibilidad en Edificación Industrial: MIVES. Universidad Politécnica de Valencia, Universitat Politècnica de Catalunya and Labein-Tecnalia, Bilbao, Spain, pp 59–70

Josa A, San José T and Cuadrado J (2008) El caso de la EHE. In Jornada sobre Sostenibilidad en la Tecnología del Hormigón: MIVES, una Herramienta de Apoyo a la Toma de Decisiones, Barcelona, pp 84–95

Josa I, Pons O, de la Fuente A, Aguado A (2020) Multi-criteria decision-making model to assess the sustainability of girders and trusses: case study for roofs of sports halls. J Clean Prod 249

MacAskill K, Guthrie P (2013) Risk-based approaches to sustainability in civil engineering. Proc Inst Civil Eng Eng Sustain 166(4):181–190

Manni E, Rimoldi P (2006) A complex segmental concrete block retaining wall structure for the reconstruction of a historical bridge. In: Proceedings ICG 8—8th international conference on geosynthetics. Yokohama

Pujadas P, Pardo-Bosch F, Aguado-Renter A, Aguado A (2017) MIVES multi-criteria approach for the evaluation, prioritization, and selection of public investment projects. A case study in the city of Barcelona. Land Use Policy 64:29–37

Rimoldi P (1996) Geogrid reinforced walls, slopes and landslides: technical solutions and construction methods. In: Proceedings international seminar on environmental geotechnology with geosynthetics—INTSEMEGG ‘96. New Delhi

Rimoldi P (2018) Design and construction of reinforced walls in Italy in complex static and seismic conditions. In: Proceedings 11ICG, 11th international conference on geosynthetics. Seoul

Rimoldi P, Ricciuti A (1992) The role of geogrid reinforced embankments in landslide stabilization: theory and practice in Italy. In: Proceedings 6th international symposium on landslides. Christchurch

Rimoldi P, Scotto M (2012) Hybrid reinforced soil structures for high walls and slopes. In: Proceedings GeoAmericas 2012 conference Lima

Rimoldi P, Lelli M, Pezzano P, Trovato F (2021) Geosynthetic reinforced soil structures for slope stabilization and landslide rehabilitation in Asia. In: Vilímek V et al (eds) Understanding and reducing landslide disaster risk. ICL contribution to landslide disaster risk reduction. Springer Nature, Switzerland, pp 397–404

Saaty T (2008) Decision making with the analytic hierarchy process. Int J Serv Sci 1(1):83–98

Stucki M, Büsser S, Itten R, Frischknecht R and Wallbaum H (2011) Comparative life cycle assessment of geosynthetics versus conventional construction materials. Eur. Ass. of Geosynthetics Manufacturers, ESU-services, Uster, ETH Zürich

Viñolas B (2011) Applications and methodology advances in MIVES multicriteria valorations. Doctoral thesis. Universitat Politècnica de Catalunya·BarcelonaTech

WCED (World Commission on Environment and Development) (1987) Our common future: report of the world commission on environment and development. Oxford University Press, Oxford, UK

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this chapter

Cite this chapter

Damians, I.P., Miyata, Y., Rimoldi, P., Touze, N., Kraus, J. (2023). Sustainability of Geosynthetics-Based Landslide Stabilization Solutions. In: Sassa, K., Konagai, K., Tiwari, B., Arbanas, Ž., Sassa, S. (eds) Progress in Landslide Research and Technology, Volume 1 Issue 1, 2022. Progress in Landslide Research and Technology. Springer, Cham. https://doi.org/10.1007/978-3-031-16898-7_14

Download citation

DOI: https://doi.org/10.1007/978-3-031-16898-7_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-16897-0

Online ISBN: 978-3-031-16898-7

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)