Abstract

Spectral element framework for slope instability analysis includes Spectral Element Method (SEM) formulation, system requirements for serial and parallel computations, model preparation with hexahedral meshing in Cubit or Trelis, meshing and mapping technique (h- and p-refinement techniques) according to SEM, applying boundary conditions for 2D and 3D, defining inputs for material model, ground water table, seismic loading as well as processing and visualizing the results in Tecplot and ParaView. Within this framework, the safety factor in slope stability is computed and visualized with greater spectral accuracy and stability.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Spectral element method (SEM) along with meshing and mapping technique is discussed by Patera (1984), Canuto et al. (1988), Serini (1994), Faccioli et al. (1997), Komatitschi and Vilotte (1998), Komatitsch and Tromp (1999), Peter et al. (2011), Gharti et. al. (2012) and Tiwari et al. (2013), and so on. In this article, we introduce and discuss SEM techniques and tools required for the use of a SEM program called ‘Specfem_Geotech’ developed by Gharti et al. (2011, 2012). This program is parallelized using message passing interface (MPI) according to Gropp et al. (1994) and Pacheco (1997), based on the domain decomposition method and implements open-source graph partitioning library ‘SCOTCH’ to separate the domain according to Pellegrini and Roman (1996). The program employs some of the codes from the ‘Programming the finite element method book’ written by Smith and Griffiths (2004) and the element-by-element preconditioned conjugate gradient method according to King and Sonnad (1987) and Barragy and Carey (1988) to solve linear equations. The Mohr–Coulomb failure criterion in the visco-plastic strain method has been implemented as per Zienkiewicz and Cormeau (1974). Along with these techniques and tools, the meshing tool ‘Cubit’ or ‘Trelis’ (www.cubit.sandia.gov) is used for hexahedral meshing, and visualization tools like ‘Tecplot Focus2016R1’ (www.tecplot.com) and ‘ParaView’ (www.paraview.org) are used to visualize the results in 2D and 3D. The following numerical tools are used to compute safety factor in slope instability analysis (Table 1).

2 SEM Approach

The FEM (i.e., Finite Element Method) is not efficient to integrate high-order polynomial equations and demands a more sophisticated computing facility since it requires solving a whole mass matrix. Fine meshes are required for the numerical convergence and consideration of progressive failure also demands an increased number of iterations. In this context, a high-order FEM, known as SEM, is employed to evaluate the stability of slopes.

SEM employs nodal quadrature, namely, Gauss-Legendre-Lobatto quadrature. In nodal quadrature, interpolation nodes coincide with integration points. The coincidence of integration and interpolation points has two main advantages: (1) interpolation is not necessary to determine nodal quantities from quantities at quadrature points and vice-versa, thus simplifying the computation of the stiffness matrix, strain, stress, etc. and (2) interpolating functions become orthogonal on quadrature points, resulting in a diagonal mass matrix, thereby simplifying the time-consuming algorithm (Fig. 1). SEM method adopts the geometric flexibility of finite elements and implements high order polynomial equations, which lead to high numerical stability as well as reliable spectral accuracy in less computing time.

3 Model Tests

3.1 H-Refinement

H-refinement refers to the change in the mesh size of a numerical model. In FEM, the H-refinement technique is often employed in the region having irregular geometry. However, Cubit/Trelis does not have the ability to refine mesh in a particular region. Hence, the mesh size of the entire model is varied and tested for variation of factor of safety (FOS) and computation time. The H-refinement technique is shown in Fig. 2, and the models with varied mesh sizes (i.e., Element size: 2–4 m and Elemental budget: 1968–268 Nos.) are illustrated in Fig. 3a–d. The overall SEM approach is shown in Fig. 4, which also includes numerical tests. Spectral and elastoplastic tests are also indicated. The spectral test includes (1) modelling domain, (2) boundary condition, (3) h- and p-refinement, and (4) spectral accuracy while the elastoplastic test includes phi-nu inequality, elastic modulus, poisson’s ratio, and material dilation.

Spectral meshing technique (as per Tiwari et al. 2013)

To evaluate the stability of landslide slopes the numerical scheme shown in Fig. 4 needs to be followed. The numerical and computational scheme accommodates hexahedral meshing and mapping techniques along with material and model preparation.

The results from the H-refinement test are shown in Table 2 and Fig. 5.

The test showed that a mesh size of 2.5 m yields factor of safety (FOS) accurately with the least computation time. Hence, a mesh size of 2.5 m has been adopted in batch processing.

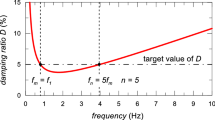

3.2 P-Refinement

Accurate numerical computation can be varied by varying the degree of the polynomial of the shape function. A P-refinement test is performed to determine the GLL value that yields FOS with reasonable accuracy with the least computation time. The mapping technique in SEM is shown in Fig. 6.

Spectral mapping techniques (Tiwari et al. 2013)

The results obtained from the test are as illustrated in Table 3 and Fig. 7.

3.3 Partitioning

To understand the effect of parallel processing on computation time, a domain having 2568 elements is decomposed into various partitions, as visualized in Fig. 8. Domain is decomposed such that the number of partitions is equal to the number of cores intended to be used for simulation. The results obtained from the simulation are shown in Table 4 and Fig. 9.

From the P-refinement test, GLL 3 was found to yield FOS with reasonable accuracy in the least time. Hence, GLL 3 was adopted batch processing.

Figure 9 shows that parallel processing is significantly faster than serial processing. There is almost a one-fourth reduction in computation time while using four cores as compared to a single core. However, the rate at which the computation time decreases onwards is very gradual. Hence, an increase in the number of processors does not necessarily mean a reduction in computation time. It depends on system configuration and must be tested independently for each system for optimum results.

Procedure for the computation of factor of safety for all the model combinations is carried out as shown in the flow charts below (Figs. 10 and 11). The procedure is divided into two stages. In the first stage, the basic slope models are prepared and various tests such as H, P refinements, and quality checks are performed in the local PC. Once the models are found suitable for the purpose of computation of FOS, they are uploaded to the server. The codes are executed in the order as shown in the flowcharts to generate the simulation files for Specfem3D_Geotech, to generate a batch file for the execution of the simulation, and to extract FOS after all the simulations are completed. Figures 10 and 11 show respectively the detailed procedure followed on a local PC and a server.

The function of each code is listed below:

-

Code-1: Generates simulation files Specfem3D_Geotech, generates batch file to execute all simulations without human intervention.

-

Code-2: Checks the results of the completed simulation and determines if models have undergone plastic deformation. Generates Batch file for the models that are yet to undergo plastic deformation.

-

Code-3: Extracts FOS from the results and generates Charts for Tecplot focus2016R1 or Tecplot 360 for all models.

In this method, we have employed strength reduction technique to get critical value of factor of safety (Griffiths and Lane 1999; Chen et al. 2007). Stability by strength reduction is a procedure where the factor of safety is obtained by weakening the soil in steps until the slope “fails.” The factor of safety is deemed to be the factor by which the soil strength needs to be reduced to reach failure. This method allows systematic reduction in soil strength by introducing SRF to reduce the frictional and cohesion component of shear strength of the basic equation of \(\tau = \sigma \tan \phi^{^{\prime}} + c^{^{\prime}}\).

where, \(\upphi_{{\text{f}}}^{{\prime}}\) and \({\text{c}}_{{\text{f}}}^{{\prime}}\) are known as reduced angle of internal friction and cohesion. In this method, a nodal displacement is significantly observed at a failure point and the points after failure initiation need several iterations to converge to a solution. Boundary conditions have significant effects on stability of slopes. FOS varies as per boundary conditions. In general, there are four kinds of boundary conditions (Fig. 12).

-

(1)

Vertical rollers at left, right as well as front and rear faces, and fixed boundary at the bottom face,

-

(2)

Vertical rollers at left, right, and rear faces and fixed at front and bottom faces,

-

(3)

Vertical rollers at left, right, and front faces and fixed at rear and bottom faces, and

-

(4)

Vertical roller boundary at left and right faces and fixed boundaries at front, rear, and bottom faces.

4 Modeling with Specfem3D_Geotech

It is a free and open-source command-driven program for 3D landslide slope stability analysis based on the SEM. The program can run in a serial and parallel or in multi-core machines or in large clusters. The program is written in FORTRAN 90 and parallelized using message passing interface (MPI or openMPI) based on the domain decomposition method. The open-source graph partitioning library SCOTCH is used for the domain decomposition. This program does not have inbuilt meshing. It does not automatically determine the FOS of slope stability. After plotting the series of safety factors versus maximum displacement, FOS can be determined for the given slope.

4.1 System Requirement

To run the serial and parallel version of Specfem3D_Geotech program, Linux working environment is required by either installing Cygwin program on computer of window operating system or making Linux operating system. While installing the Cygwin, the following platforms are selected accordingly (www.cygwin.com).

Base (automatically selected)

Gcc-core–GNU Complier collection (C, openMP)

Gccfortran

Make-The GNU version of make utility

Automake 1.10

Openssl-openssl

Openssl devel

Openssl100

Ssh-(autossh, libssh2-devel, libssh2_1, openssh)

Vim-(gvim, vim and vimcommon)

Scp

Ftp-(lftp, tftp, tftp Server)

Shell-xterm-emulator and

Utilities-cygutilities

To assure the correctly installation, type ‘gfortran’ in a command prompt and make sure that there is a display of text ‘no input found.’ If Command prompt does not display such text, the program is not installed correctly.

4.2 Model Preparation

Exact topography is needed to make a realistic model. The surface complexity of the model depends on the contours available. Therefore, contours of the suitable interval must be chosen to simplify the model. A total station survey would be good enough to capture the detail topographic features by producing contours of suitable intervals of the area. Based on those contours, both 2D and 3D models are prepared. If there is no such case of doing a topographic survey and producing exact contour maps, topographic data can be explored from Google Earth or any other similar tools and techniques.

4.3 2D Models

Following three steps must be followed to prepare 2D models.

-

(1)

Extracting the topographic data from Google earth. To extract topographic data from Google earth, following steps must be followed.

-

(i)

Create path in Google Earth within the study area (set distance in meter),

-

(ii)

Name the drawn path in step (1) and click on ‘ok’

-

(iii)

Right click on the path of temporary location and save as my places in ‘.kml’ format in required location (for example: Jure.kml, Jure landslide, Sindhupalchowk, Nepal (27° 46′1.55″ N latitude and 85° 52′17.10″ E longitude))

-

(i)

-

(2)

Save extracted ‘.kml’ file to ‘.csv’

To save the extracted ‘.kml’ file to ‘.csv,’ following steps must be followed.

-

(i)

Open TCX converter,

-

(ii)

Open the file in TCX converter (open Jure.kml),

-

(iii)

Click on track modify and then update altitude (the altitude initially shows zero value after updating the RL above mean sea level appears), and

-

(iv)

Export the file in ‘.csv’ format (for example: Jure.csv).

-

(i)

-

(3)

Preparing model in AutoCAD CIVIL3D

The 2D models must be prepared in AutoCAD CIVIL3D program in the following manner.

-

(i)

Open AutoCAD CIVIL 3D,

-

(ii)

Import the file in keep point format NEZ (The latitude and longitude degree should be multiplying by 111000 m) (Zoom extents if imported points not visible),

-

(iii)

Create TIN surface,

-

(iv)

Add points to surface and manage surface properties to display the contour interval,

-

(v)

Create alignment with alignment creation tools. We created left section (1-1), Middle (2-2), Right (3-3) in case of Jure landslide,

-

(vi)

Create profile,

-

(vii)

Draw polyline above profile line. Draw the closed polyline as per the required strata of the model,

-

(viii)

Move the polyline drawn in step (vii) to the origin, and align with ‘xz’ face by rotation, so that it is easier to give dimensions,

-

(ix)

Extrude the 2-D surface to required depth and

-

(x)

Save the solid extruded volume to ASCI ‘.sat’ format (for example: Jure.sat).

-

(i)

4.4 3D Models

To create 3D model, three major steps of 2D model i.e., (1) Extracting the topographic data, (2) how to save extracted data and (3) model preparation in AutoCAD CIVIL3D up to 1–4 steps each would be same and then follow the following steps:

-

(1)

The prepared surface is in 3D surface, view it in different styles like isometric or any custom view by 3D orbit rotator,

-

(2)

Choose the contour interval accordingly as the size of the study area (for example 20 m intervals in Jure landslide),

-

(3)

Draw splines over contour with best fit,

-

(4)

Copy the drawn contour to the new location, visualize them and found match with original contour, Creates the surface of the contours with loft command. Select cross-section only for lofting option,

-

(5)

Use thicken command to convert surface to volume (Because the import of cubit should be volume object and .sat format),

-

(6)

Then draw a box using ‘BOX’ command of exact model size (The model size should be less then counter surface to operate subtract command),

-

(7)

Move the box to volume created so that volumes clearly intersect the box,

-

(8)

Use ‘SUBTRACT’ command to subtract volume created in ‘7)’ from the box (1st select the box and then the volume),

-

(9)

Then use ‘SEPARATE’ command to separate the subtracted volume,

-

(10)

Delete the upper surface,

-

(11)

Extend the box in z-direction to get the model according to the required depth of the model,

-

(12)

Move the object or align the object with co-ordinate (0, 0, 0) with front face left side bottom vertex as origin and

-

(13)

The model prepared in AutoCAD 3D is exported to ‘.SAT’ file format.

4.5 Models in Cubit/Trelis

The process of preparing 2D and 3D models in Cubit is more or less similar except in selecting their boundary conditions. The 2D model can also directly be prepared in Cubit if (x, z) coordinatse of each profile points are known. The easiest way to prepare model here would be by creating solid model in AutoCAD in the following manner (Figs. 13 and 14).

-

(1)

The SAT file prepared in AutoCAD 3D is imported in cubit (Jure.sat) and

-

(2)

To prepare meshable body and to check mesh quality, following works must be done.

-

(i)

Run heal analyzer to remove invalid topology,

-

(ii)

Remove small surfaces,

-

(iii)

Modify blend surfaces,

-

(iv)

Decompose volume,

-

(v)

Set sources and targets and

-

(vi)

Force sweep topology.

-

(i)

Above work can be done form power tool, command panel and command line. Next steps of this process are as follows.

-

(3)

‘Imprint all’ command merges all for sharing of same surface if adjacent volume,

-

(4)

Meshing operation can be done with the following steps: command panel—meshing—volume—intervals—selecting volume—constant size and giving the size of mesh,

-

(5)

To check mesh quality, following steps would be followed: command panel—meshing—volume—mesh quality—quality metrics—selecting volume—quality metric (shape)—picking the choice display graphical summary,

-

(6)

By seeing the graphical summary of the mesh quality, number of mesh of that quality, we decided the way to decompose the model i.e., orientation of cutting,

-

(7)

To decompose the volume, there is a different method of cutting in Cubit: command panel—volume—web cut: we use the various web cut method according to suitability of orientation and location of cutting plane,

-

(8)

If the mesh quality is not found good enough then steps 5–7 would be repeated with different meshing and mapping scheme,

-

(9)

Then do ‘Compress all,’

-

(10)

Then, define all volumes of blocks,

-

(11)

Define surfaces as sideset for the implementation of boundary condition,

-

(12)

Define boundary condition according to the real field scenario.

-

(13)

Then the model is exported as exodus file (.exe) to Directory/text/utilities and saved as .e file.

The SEM program reads text files only. The exodus files from Cubit/Trelis need to be changed to a text file. Then, the .SEM file is edited as per requirement according to process mentioned in editing .SEM file.

Figure 14 shows the hexahedral meshing in the 3D domain along with quality meshing and mapping. Inaccuracy of the result and termination of the program is mainly due to the lack of quality meshing and mapping. Thus, h- and p- refinement techniques are employed to limit the numerical and computational errors. The numerical and computational stability can only be achieved if proper h- and p- refinement efforts have been employed in the model.

5 Inputs for Specfem3D_Geotech

5.1 Material Properties

The material model is prepared with six soil parameters. They are gamma, ym, nu, phi, coh, and psi. Here, ‘gamma’ is the unit weight of the soil, ‘ym’ is the Young’s Modulus of soil, ‘nu’ is the Poission’s ratio, ‘phi’ is the angle of internal friction of soil, ‘coh’ is the cohesion coefficient, ‘psi’ is the dilation angle.

5.2 Ground Water Table (GWT)

To prepare the input file of ground water table, position of GWT at borehole locations should be identified.

5.3 Seismic Input

The horizontal seismic acceleration in Nepal varies from 0.1 to 0.5 g. Direction of acceleration may vary with respect to the orientation of slope. After the completion of computations, ‘.case’ and ‘summary’ files can be viewed in Tecplot and Paraview. Tacplot and Paraviews are the powerful visualization tools for 2D and 3D.

5.4 Output Visualization

The output of the SEM program can be visualized in different forms .DAT file is prepared based on summary file in the form of ‘SRF,’ non- linear iterations (NL_ITERs) (numbers) and maximum displacement (UMAX) (m). DAT file is then sopened to Tecplot focus2016 R1 program to plot the graph of SRF versus maximum displacement and SRF versus NL_ITERs. Scaling and sizing different features of graph are edited with various tools as per requirements.

The factor of safety is then determined as per the judgment on critical factor of safety. The critical value of SRF is a point where displacement is abruptly changed to maximum. It can be further correlated with non-linear iteration. At certain SRF, the non-linear iteration is also suddenly changed to maximum value. The factor of safety is then interpreted with different variables like dry condition, fully saturated conditions, and seismic motion condition. The progressive failure can be visualized in 3D visualization tool Paraview by opening ‘.case’ files. The results can be captured or exported to ‘.jpg’ file format.

Tacplot is used to visualize results in 2D. Data management and further editing, if any, would be possible in Tacplot focus program. As an example, notepad or text file ‘.txt’ can be prepared in for two variables: (1) strength reduction factor (SRF) and (2) maximum Displacement (m). SRF varies from 0.1 to 1.2, altogether inserted 12 values in case first. Similarly, displacement values in each SRF are needed in each case of modeling.

The material model presented in Table 5 below for debris is taken from USCS soil classification system as adopted by Krahenbuhl and Wagner (1983). The material model for rock is taken as: (1) Material: Schist inter bedded with Phyllite, (2) Failure Criteria: Mohr–Coulomb, (3) Unit weight = 27 kN/m3, (4) Modulus of elasticity of rock mass = 29,903,000 kPa ≈30 MPa, (5) Poisson ratio = 0.3 and (6) Angle of internal friction = 32.50° (as per Hoek and Diederichs 2006; Hoek 2007). The pseudostatic seismic stability of the slope is proposed. In Jure area, the maximum PGA is 250 gal according to the seismic hazard map developed by Department of Mines and Geology (Pandey et al. 2002). So, the seismic loading PGA of 0.1 to 0.5 g are varied in the models accordingly.

Figure 15 shows the computational results in varying groundwater and seismic slope condition: (a) Displacement (m) versus SRF at dry and GWT at the surface and (b) Displacement (m) versus SRF seismic loading condition in case of Jure landslide model, Nepal. The abrupt change in slope as noticed would be the critical SRF. Similar results can be obtained in 2D domains. However, the complexity of the domain can be well captured in 3D domains as compared to 2D. The safety factor thus obtained in 3D models seems to be more accurate than the 2D if the complexity issue of the modelling domain is well addressed. In this way, the SEM scheme replaces the huge computational burden in FEM. SEM approach can be employed for soil and rock slopes.

6 Conclusions

Spectral element method is an elegant formulation of the FEM with a high degree piecewise polynomial basis. In this method, the interpolation nodes of an element and the numerical integration points are cited in the same points. Here, with the coincidence of integration and interpolation points, the interpolating functions become orthogonal, resulting in a diagonal mass matrix, which significantly simplifies the computational procedures and drastically reduces the computational costs. The SEM procedure has three major benefits over the existing FEM procedures: (1) geometrical flexibility, (2) high computational efficiency, and (3) reliable spectral accuracy (i.e., exponential reduction of errors with increasing degree of polynomials). The higher spectral degree in SEM replaces the huge computational burden of FEM. Then, the safety factors thus obtained seems to be accurate values as per the material properties and slope model supplied which can encouragingly be used in effective design and implementation of various landslide slope stability works.

References

Ahrens J, Geveci, B, Law, C (2005) ParaView: an end-user tool for large data visualization, visualization handbook, Elsevier. ISBN-13: 978-0123875822. http://www.paraview.org. Last Accessed 18 Jul 2021

Anderson DA, Tannehill JC, Pletcher RH (1984) CUBIT 15.3 user documentation, SAND2017-6895 W. Sandia National Laboratories. http://www.cubit.sandia.gov. Last Accessed 17 Jul 2021

Barragy E, Carey GF (1988) A parallel element-by-element solution scheme. Int J Numer Meth Eng 26(11):2367–2382

Canuto C, Hussaini MY, Quarteroni A, Zang TA (1988) Spectral methods in fluid mechanics. Springer, Berlin. https://doi.org/10.1007/978-3-642-84108-8

Chen JX, Ke PZ, Zhang G (2007) Slope stability analysis by strength reduction elasto-plastic FEM. Key Eng Mater 345–346:625–628. https://doi.org/10.4028/www.scientific.net/kem

Cygwin (2021) This is the home of the Cygwin project. http://www.cygwin.com. Last Accessed 15 June 2021

Faccioli E, Maggio F, Paolucci R, Quarteroni A (1997) 2D and 3D elastic wave propagation by a pseudo-spectral domain decomposition method. J Seismolog 1(3):237–251

Gharti HN, Komatitsch D, Oye V, Martin R, Tromp J (2011) SPECFEM3D_GEOTECH 1.0 Beta User Manual

Gharti HN, Komatitsch D, Oye V, Martin R, Tromp J (2012) Application of an elastoplastic spectral-element method to 3D slope stability analysis. Int J Num Methods Eng 91(1):1–26

Griffiths DV, Lane PA (1999) Slope stability analysis by finite elements. Geotechnique 49(3):387–403

Gropp W, Lusk E, Skjellum A (1994) Using MPI, portable parallel programming with the message passing interface. Computing and processing. MIT press, Cambridge, USA, p 336. ISBN: 9780262527392

King RB, Sonnad V (1987) Implementation of an element-by-element solution algorithm for the finite element method on a coarse-grained parallel computer. Comput Methods Appl Mech Eng 65(1):47–59

Krahenbuhl, J, Wagner A (1983) “Survey, design, and construction of trail suspension bridges for remote areas”, SKAT. Swiss Center for Appropriate Technology in St. Gallen, Switzerland. Survey, design, and construction of trail suspension bridges for remote areas. (OCoLC) 692980053

Komatitsch D, Tromp J (1999) Introduction to the spectral element method for the three-dimensional seismic wave propagation. Geophys J Int 139(3):806–822

Komatitsch D, Vilotte JP (1998) The spectral element method, an efficient tool to simulate the seismic response of 2D and 3D geological structures. Bullet Seismol Soc Am 88(2):368–392

Law KH (1986) A parallel finite element solution method. Comput Struct 23(6):845–858

Pacheco P (1997) Parallel programming with MPI. Morgan Kaufmann Publishers Inc.340 Pine Street, Sixth Floor San Francisco, CA, United States, p 418. ISBN:978-1-55860-339-4

Patera AT (1984) A spectral element method for fluid mechanics: laminar flow in a channel expansion. J Comput Phys 54(3):468–488

Pellegrini F, Roman J (1996) Scotch: A software package for static mapping by dual recursive bipartitioning of process and architecture graphs. In: Liddell H, Colbrook A, Hertzberger B, Sloot P (eds) High-performance computing and networking. HPCN-Europe 1996. Lecture Notes in Computer Science Vol 1067. Springer, Berlin, Heidelberg, pp 493–498

Peter D, Komatitsch D, Luo Y, Martin R, Le GN, Casarotti E, Le LP, Magnoni F, Liu Q, Blitz C, Nissen-Meyer T, Basini P, Tromp J (2011) Forward and adjoint simulations of seismic wave propagation on fully unsaturated hexahedral meshes. Geophys J Int 186(2):721–739

Seriani G (1994) 3D large-scale wave propagation modeling by spectral element method on Cray T3E multiprocessor. Comput Methods Appl Mech Eng 164(1):235–247

Smith IM, Griffiths DV (2004) Programming the finite element method. John Wiley and Sons and location. (ISBN_number_)

Tecplot (2021) Tacplot. http://www.tecplot.com. Last Accessed 20 Jul 2021

Tiwari RC, Bhandary NP, Yatabe R (2013) High-order FEM formulation for 3-D slope instability. Appl Math 4(5A). https://doi.org/10.4236/am.2013.45A002

Zienkiewicz O, Cormeau I (1974) Visco-plasticity—plasticity and creep in elastic solids—a unified numerical solution approach. Int J Numer Meth Eng 8(4):821–845

Acknowledgements

We would like to acknowledge the Japanese Society for the Promotion of Science (JSPS) for providing this research opportunity. We would also like to acknowledge Mr. Pujan Giri, M.Sc. Student in Geotechnical Engineering, Institute of Engineering, Pulchowk Campus, Tribhuvan University for his effort in numerical and computational works.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this chapter

Cite this chapter

Tiwari, R.C., Bhandary, N.P. (2023). Application of Spectral Element Method (SEM) in Slope Instability Analysis. In: Sassa, K., Konagai, K., Tiwari, B., Arbanas, Ž., Sassa, S. (eds) Progress in Landslide Research and Technology, Volume 1 Issue 1, 2022. Progress in Landslide Research and Technology. Springer, Cham. https://doi.org/10.1007/978-3-031-16898-7_11

Download citation

DOI: https://doi.org/10.1007/978-3-031-16898-7_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-16897-0

Online ISBN: 978-3-031-16898-7

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)