Abstract

Optimization of the temporal aspects of task design requires a better understanding of the development of muscle fatigue over time. The study was aimed to use wearable devices to continuously investigate muscle fatigue in the right forearm of 12 assembly workers. Indicators of fatigue were obtained through surface electromyography (sEMG) and ratings of perceived discomfort during daylong assembly tasks. Average EMG amplitude increased over the work day while median frequency decreased. Local perceived fatigue in the shoulder, upper arm, forearm and wrist increased over the course of the day. However, no clear relationship between perceived fatigue and objective indicators of fatigue was found. Using the wearable monitoring sensors, it is promising to improve worker-supervisor fatigue management in real time. This study might further help in the definition and justification of temporal interventions such as changing the length of the working day, adding extra pauses or task variation across time.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Although technological advancements have reduced the number of heavy manual operations for workers, work-related musculoskeletal disorders (WMSDs) remain a widespread issue leading to increased financial and societal costs [1, 2]. Several risk factors are known to be associated with WMSDs. Among the most commonly accepted physical risk factors are exposure to tasks involving high force demands, tasks involving high rates of repetition, tasks involving awkward postures, and tasks of long duration [3,4,5]. Light-assembly work is a clear example of work with low force demand, high rates of repetition and long duration. Therefore, assembly workers are exposed to elevated risks of WMSDs [6,7,8].

To reduce WMSDs risk and to improve health and performance at the workplace, the work intensity of musculoskeletal loads should be ensured within safety limits. When work intensity is too high for workers, industrial manager should affect the temporal pattern of the load using effective strategies, which may concern the length of the working day, the work pace, the work-rest scheme or variations in tasks [9].

Work intensity could be estimated by preventive measurements concerning physical fatigue. Muscle fatigue is an important initiating factor in the development of WMSDs. Muscle fatigue, when measured during work, may provide a relevant biomarker for cumulative exposure to repetitive work [10]. A good understanding of the development of muscle fatigue over the course of a working day might be helpful to define the optimal time pattern of the work.

The development of muscle fatigue at repetitive and low-intensity tasks in real or simulated work conditions has been studied on the basis of objective measurements (mainly electromyography (EMG)) and subjective rating scales. Suurküla and Hägg [11] investigated the development of muscle fatigue in the trapezius and infraspinatus muscles after 2 h working at the workplace. EMG variables measured in a test contraction showed a trend towards fatigue, but this was not statistically tested. Mathiassen and Winkel [9] studied the assembly of starters of power saws. In a laboratory setting, they also found a trend towards increased muscle fatigue in the trapezius muscle over the course of a simulated 6-h working day (with a 10% increase of amplitude and a 2.5% decrease in frequency content) but these changes were only partially significant. Perceived fatigue increased significantly during the working day. Bennie et al. [12] and Dennerlein et al. [10] investigated an isolated repetitive ulnar deviation task at a low intensity level during a simulated 8-h working day. Electrostimulation and EMG measurements of the extensor carpi ulnaris were used to detect muscle fatigue. A subjective rating scale was used to investigate the development of local perceived fatigue. Both objective measurements showed an increase in muscle fatigue over the course of an 8-h working day in the absence of perceived fatigue.

The EMG signals in previous studies were obtained in test contractions during breaks at work, not in the real dynamic assembly tasks [10, 11]. These test contractions cannot represent the workload and thus of the muscle behavior during the real tasks [13, 14]. In addition, the EMG measurement in previous studies just took place at several moments during the working day. The discrete measurements of EMG cannot provide the continuous real-time information for muscle fatigue management.

The difficulty of measuring EMG continuously in the real assembly tasks may be due to the disadvantage of the traditional EMG equipment. Traditional EMG devices are expensive and delicate and have many wires connected with electrodes which would disturb normal action of workers. Therefore, it is unrealistic for assembly workers to operate, move or take a coffee as normal when they are equipped with electrodes and wires.

The wearable sensors could be a solution for EMG measurement in industrial settings [15, 16], since it is cheap and easy to use, equipped with wireless transmission capabilities, which minimizes the disturbance caused by instrumentation to the users. Wearable sensors are becoming stretchable and easy to attach to the human body [17]. Montoya et al. [18] showed the feasibility of using one kind of new wearable physiological computing systems, the Myo Armband to measure EMG where high accuracy levels of EMG signal were not required.

Wearables device is an emerging approach and suitable to be applied in natural manufacturing settings, but few pieces of research have been conducted till this day on using wearable devices for detecting/predicting muscle fatigue. Therefore, this paper aimed to use wearable armbands with built-in EMG electrodes to measure muscle fatigue of assembly workers in a mobile phone manufacturing company during a 10-h working day. The general questions that this study tried to answer were:

-

how do objective estimates of muscle fatigue in the forearm develop over a 10-h low-intensity assembly work?

-

how do subjective feelings of local fatigue develop during a 10-h low-intensity assembly work?

2 Methods

This study was carried out in a production line of a Chinese manufacturer of electrical products. Twelve subjects (four males and eight females) participated in the study. Table 1 shows the demographics of the sample. None of the subjects reported any musculoskeletal disorders. All subjects were experienced assemblers (with 1.61 ± 1.11 years of experience). The subjects gave their written informed consent prior to the start of the study.

These subjects assembled electrical products by picking and placing small parts (Fig. 1). They also performed the quality control for their own work by visual inspection. The work was monotonous, low-intensity with static neck posture and repetitive arm lifting. There was no regular task rotation. Workers were paced by a driven production line. The work pace was indirectly defined by a target (products per hour), but employees could take micro-breaks during the day. The intensity of the trapezius muscle load was estimated at 5% MVC. The subjects worked 10 h per working day which started at 07:30 and ended at 17:30. Two rest breaks of 15 min were taken in the morning and the afternoon. There was a standard 60 min lunch break. Each subject’s measurements (described in Fig. 2) took the whole working day.

2.1 Measurements

Electromyography.

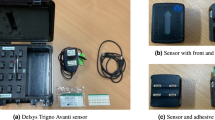

Surface EMG was measured by wearable EMG devices for nearly 9 h (Myo Armband; Thalmic Labs, Waterloo, Ont). The Myo Armband was placed at the end of the right forearm near the elbow (see Fig. 3(a, b)). The EMG signals were collected by eight electrodes embedded in the Myo armband. These electrodes collected mixed signals from all muscle groups in the forearm (the extensor carpi radialis longus, flexor carpi radialis longus, extensor carpi redialis brevis, flexor carpi redialis brevis, extensor digitorum communis, flexor digitorum communis, extensor digiti minimi, flexor digiti minimi, extensor carpi ulnaris and flexor carpi ulnaris). The electrodes embedded in the armband were cleaned with alcohol each working day. Before the electrodes were applied, the skin was shaved, scrubbed and cleaned with alcohol. Skin resistance was not measured. Raw EMG signals were sampled with a frequency of 200 Hz. The EMG data were recorded as a unitless integer for each sensor representing “activation” and did not translate to volts (V) or millivolts (mV). The EMG signals obtained by eight electrodes were highly correlative, then we used the average EMG signal to describe the fatigue of forearm muscles.

The processing of the EMG signals was performed using the Matlab (R2014, MathWorks, Natick, MA). For the signal filtering, a fourth order Butterworth filters were used with cutoff frequencies from 20 Hz to 100 Hz. A fourth-order rejection Butterworth was applied to signals from 58 Hz to 72 Hz, which filters the noise of the cardiac signal and the signal from the power line [19]. The amplitude values were normalized to the maximum EMG value obtained from the same muscle. To find the muscle fatigue markers (average EMG amplitude (AEMG) and the median frequency (MF)), a moving average window of 200 samples and an overlap of 50 samples was applied to the filtered EMG signals. The median frequency (MF) was analyzed using a fast Fourier transformation in each sliding window.

Perceived Exertion.

Fatigue was also measured using the Borg Rating of Perceived Exertion [20]. A body map consisting of four regions was presented to the subjects, including the shoulder, right upper arm, right forearm and right wrist. Subjects were asked to rate perceived exertion in the regions identified on a 6–20 point-scale (ranging from 6 = no exertion at all to 20 = maximal exertion). In this study, perceived exertion measurements were performed every one or two hours (before starting, 09:30, 10:30, before and after the lunch break, 14:00, 15:00, 16:00 and at the end of the day). The highest perceived exertion score in the four regions was defined as the fatigue score.

2.2 Statistical Analysis

Data were analyzed with a repeated measures ANOVA to compare the independent variables (time moments) for all dependent variables (EMG median frequency (MF), mean amplitude (AEMG) and local perceived fatigue). p-Values were based on degrees of freedom corrected with Greenhouse-Geisser’s epsilon to compensate for the effects of violations of the sphericity assumption. A Student t-test was used as the follow-up test for comparisons of means. Pearson’s product moment correlation was calculated to determine the relation-ships between objective EMG variables and discomfort. Significance was accepted at p < 0.05.

3 Results

3.1 Mean Power Frequency and Amplitude of the Electromyography

As shown in Fig. 4(a) and (b), for the mean amplitude (AEMG) of the EMG signal, a main effect of time was found (F(9.25, 101.77) = 14.23, p < 0.001, \( \upeta^{2} \) = .56). A post-hoc test revealed a significant increase in three periods: from 08:30 to 09:00 (p < 0.05), from 10:30 to 11:00 (p < 0.05), from 14:30 to 14:50 (p < 0.001), and a significant decrease in the period from 14:50 to 15:05 (p < 0.01).

As shown in Fig. 5(a) and (b), a significant main effect of time in the MPF were found (F(8.65, 95.15) = 3.3, p < 0.001, \( \upeta^{2} \) = 0.23). A post-hoc test revealed a significant decrease in the period from 14:30 to 14:50 (p < 0.001), and a significant increase in the period from 14:50 to 15:05 (p < 0.01).

3.2 Perceived Fatigue

Figure 6 shows the development of fatigue in the shoulder, right upper arm, right forearm and the right wrist. A main effect of time on fatigue in the four regions was found (F(3.6, 39.5) = 21.3, p < 0.001). Post-hoc tests with the Bonferroni adjustment revealed significant increases after the 10:30 (p < 0.05), before the lunch (p < 0.01), 14:00 (p < 0.001), 15:00 (p < 0.001), 16:00 (p < 0.001) and at the end of the day (p < 0.001), compared with scores before starting. The decrease in discomfort during the lunch period, which may have indicated recovery, was not significant (p = 1.0).

3.3 Correlations Between Variables

Pearson’s correlation coefficients were determined for the difference between the start and the end of the day for average EMG amplitude, MPF and perceived fatigue rating (Table 2). No relationship was found between subjective and objective estimates of muscle fatigue. Correlation coefficients were low and not significant.

4 Discussion

In the current study, the development of muscle fatigue in realistic assembly work was continuously investigated using a wearable device. This type of field research has some limitations in comparison with controlled laboratory experiments. The time period as well as the number of subjects is often restricted. In addition, there are many confounding factors related to production planning, capacity utilization, variation in products, (technical) disturbances and absence of subjects. These confounders are hard to control and have large effects. Conversely, field research has the obvious advantage that it requires no extrapolation of results to practice.

The EMG signals obtained in this field study showed indications of the development of muscle fatigue over the course of a working day. Indications of muscle fatigue include an increase of the average EMG amplitude and a decrease of the MF [21]. In this study, average EMG amplitude increased significantly during the first three periods of the day while MF only changed significantly in the third period. The production line slowed down after 16:30, and thus the AEMG and MF had a recovery trend at the fourth period of the day.

Incidences of muscle fatigue (RMS, MF and perceived fatigue) were found different between subjects. The interindividual differences are consistent with the results of other studies in which much interindividual variability in muscle activities was found in a standardized machine-paced work at a packing machine [6, 22, 23]. The variability of fatigue incidences between subjects could be due to individual fatigue patterns, which means muscle motor units recover from fatigue at different speeds for participants, or each participant would use different muscle motor units to take over the function of the fatigued muscle units. In addition, a changed position within the range of motion for the subjects could possibly explain the variable pattern of muscle fatigue. Differences in working postures, working speed and work outputs were observed during the experiment. The variability of fatigue incidences between subjects could also be due to electrodes positions. For each participant, electrode locations were visually controlled carefully, but small changes in electrode positions may have occurred and skin resistance was not controlled.

In addition to the indications of the development of objective muscle fatigue, local perceived fatigue in the shoulder, upper arm, forearm and wrist was also found to increase. Remarkably, there was no clear relationship between subjective indicators (perceived fatigue in the four regions) and the objective indicators (MF and amplitude of the EMG signal) of muscle fatigue. Sundelin and Hagberg [24] were able to find a significant relationship between subjective and objective indicators. However, that study used a 1-h strictly controlled laboratory task with a relative high intensity. No such relationship has been established so far, to the present authors’ knowledge, in field research over the course of a working day.

The absence of a relationship might be explained by several factors. First, the ratings of local perceived fatigue obtained in occupational settings might be the result of other issues rather than fatigue. For instance, the subjective interpretation of an intervention (e.g. longer working hours) might influence the subjects’ feelings of fatigue. Moreover, fatigue also encompasses sensations of other sensory experiences such as pain and pressure as well as discomfort in tissues other than the muscles. Conversely, EMG measurements reflect only a small part of the physiological state of the muscle. Changes in the MF and AEMG of the EMG signal are less consistent during pro-longed low-level dynamic contractions than during high-force contractions [13, 25]. Physiological processes not reflected in the EMG signal (e.g. local blood flow, local metabolic changes, changes in the mechanical properties of the excitation contraction coupling) may play an important role in the development of fatigue during low-intensity work.

EMG is only one objective method to estimate muscle fatigue. To get comprehensive estimate of muscle fatigue, complementary objective methods may be needed in the future research. Blangsted et al. [14] used mechanomyography (MMG) to detect fatigue during short, low-intensity static contractions. Physiological features such as motor unit recruitment and synchronization of motor units are thought to be reflected by MMG measurements [26] and could provide additional information on fatigue processes. Rosendal et al. [27] used micro dialysis to investigate intramuscular metabolism of the trapezius muscle during a 20 min repetitive low-force contraction exercise. An increase in pain was accompanied by a rise in local anaerobic metabolism. However, the use of micro dialysis in field studies is likely to be limited. An increase in discriminatory power may be required here and these methods (micro dialysis and MMG) could help to achieve field applications.

In conclusion, this study measured signs of fatigue over the whole working day using the wearable devices. Using these wearable monitoring sensors, it is promising to improve worker-supervisor fatigue management in real time. This study might further help in the definition and justification of temporal interventions such as changing the length of the working day, introducing extra pauses or task variation across time.

References

Andersson, G.: The Burden of Musculoskeletal Diseases in the United States: Prevalence, Societal and Economic Cost. American Academy of Orthopaedic Surgeons, Rosemont (2008)

Horton, R.: GBD 2010: understanding disease, injury, and risk. Lancet 380(9859), 2053–2054 (2012)

Putz-Anderson, V., Bernard, B.P., Burt, S.E., et al.: Musculoskeletal disorders and workplace factors. National Institute for Occupational Safety and Health (NIOSH), p. 104 (1997)

Hoogendoorn, W.E., van Poppel, M.N., Bongers, P.M., Koes, B.W., Bouter, L.M.: Physical load during work and leisure time as risk factors for back pain. Scand. J. Work Environ. Health 25, 387–403 (1999)

Punnett, L., et al.: Estimating the global burden of low back pain attributable to combined occupational exposures. Am. J. Ind. Med. 48(6), 459–469 (2005)

Aarås, A., Westgaard, R.H.: Further studies of postural load and musculoskeletal injuries of workers at an electro-mechanical assembly plant. Appl. Ergon. 18(3), 211–219 (1987)

Hagberg, M., Wegman, D.H.: Prevalence rates and odds ratios of shoulder-neck diseases in different occupational groups. Occup. Environ. Med. 44(9), 602–610 (1987)

Mathiassen, S.E., Winkel, J., Sahlin, K., Melin, E.: Biochemical indicators of hazardous shoulder-neck loads in light industry. J. Occup. Med. Off. Publ. Ind. Med. Assoc. 35(4), 404–407 (1993)

Mathiassen, S.E., Winkel, J.: Physiological comparison of three interventions in light assembly work: reduced work pace, increased break allowance and shortened working days. Int. Arch. Occup. Environ. Health 68(2), 94–108 (1996)

Dennerlein, J.T., Ciriello, V.M., Kerin, K.J., Johnson, P.W.: Fatigue in the forearm resulting from low-level repetitive ulnar deviation. AIHA J. 64(6), 799–805 (2003)

Suurküla, J., Hägg, G.M.: Relations between shoulder/neck disorders and EMG zero crossing shifts in female assembly workers using the test contraction method. Ergonomics 30(11), 1553–1564 (1987)

Bennie, K.J., Ciriello, V.M., Johnson, P.W., Dennerlein, J.: Electromyographic activity of the human extensor carpi ulnaris muscle changes with exposure to repetitive ulnar deviation. Eur. J. Appl. Physiol. 88(1–2), 5–12 (2002)

Søgaard, K., Blangsted, A.K., Jørgensen, L.V., Madeleine, P., Sjøgaard, G.: Evidence of long term muscle fatigue following prolonged intermittent contractions based on mechano-and electromyograms. J. Electromyogr. Kinesiol. 13(5), 441–450 (2003)

Blangsted, A.K., Sjøgaard, G., Madeleine, P., Olsen, H.B., Søgaard, K.: Voluntary low-force contraction elicits prolonged low-frequency fatigue and changes in surface electromyography and mechanomyography. J. Electromyogr. Kinesiol. 15(2), 138–148 (2005)

Tsao, L., Ma, L., Papp, C.T.: Using non-invasive wearable sensors to estimate perceived fatigue level in manual material handling tasks. In: Ahram, T. (ed.) AHFE 2018. AISC, vol. 795, pp. 65–74. Springer, Cham (2019). https://doi.org/10.1007/978-3-319-94619-1_7

Tsao, L., Li, L., Ma, L.: Human work and status evaluation based on wearable sensors in human factors and ergonomics: a review. IEEE Trans. Hum. Mach. Syst. 49(1), 72–84 (2018)

Amjadi, M., Kyung, K.U., Park, I., Sitti, M.: Stretchable, skin-mountable, and wearable strain sensors and their potential applications: a review. Adv. Func. Mater. 26(11), 1678–1698 (2016)

Montoya, M., Henao, O., Muñoz, J.: Muscle fatigue detection through wearable sensors: a comparative study using the myo armband. In: Proceedings of the XVIII International Conference on Human Computer Interaction, p. 30. ACM, September 2017

Merletti, R., Farina, D.: Surface Electromyography: Physiology, Engineering, and Applications. Wiley, New York (2016)

Borg, G.: Borg’s Perceived Exertion and Pain Scales. Human Kinetics, Champaign (1998)

Basmajian, J.V., De Luca, C.J.: Muscles Alive: Their Functions Revealed by Electromyography, 5th edn. Lippincott Williams and Wilkins, Baltimore (1985)

Kilbom, Å., Persson, J.: Work technique and its consequences for musculoskeletal disorders. Ergonomics 30(2), 273–279 (1987)

Veiersted, K.B., Westgaard, R.H., Andersen, P.: Pattern of muscle activity during stereotyped work and its relation to muscle pain. Int. Arch. Occup. Environ. Health 62(1), 31–41 (1990)

Sundelin, G., Hagberg, M.: Electromyographic signs of shoulder muscle fatigue in repetitive arm work paced by the methods-time measurement system. Scand. J. Work Environ. Health 18, 262–268 (1992)

Nussbaum, M.A.: Static and dynamic myoelectric measures of shoulder muscle fatigue during intermittent dynamic exertions of low to moderate intensity. Eur. J. Appl. Physiol. 85(3–4), 299–309 (2001)

Orizio, C., Gobbo, M., Diemont, B., Esposito, F., Veicsteinas, A.: The surface mechanomyogram as a tool to describe the influence of fatigue on biceps brachii motor unit activation strategy. Historical basis and novel evidence. Eur. J. Appl. Physiol. 90(3–4), 326–336 (2003)

Rosendal, L., et al.: Increase in muscle nociceptive substances and anaerobic metabolism in patients with trapezius myalgia: microdialysis in rest and during exercise. Pain 112(3), 324–334 (2004)

Acknowledgements

This work was supported by the National Natural Science Foundation of China [grant number 71471095] and Ministry of Science and Technology of China [grant number 2017YFC0820200 and 2016IM010200].

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Fu, J., Ma, L., Tsao, L., Zhang, Z. (2019). Continuous Measurement of Muscle Fatigue Using Wearable Sensors During Light Manual Operations. In: Duffy, V. (eds) Digital Human Modeling and Applications in Health, Safety, Ergonomics and Risk Management. Human Body and Motion. HCII 2019. Lecture Notes in Computer Science(), vol 11581. Springer, Cham. https://doi.org/10.1007/978-3-030-22216-1_20

Download citation

DOI: https://doi.org/10.1007/978-3-030-22216-1_20

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-22215-4

Online ISBN: 978-3-030-22216-1

eBook Packages: Computer ScienceComputer Science (R0)