Abstract

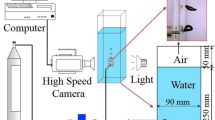

Injecting air into water serves as an effective measure of generating bubbles. The characteristics of the background water flow must exert a significant effect on the bubbles trapped. In this chapter, it is intended to reveal the bubbly flow pattern downstream of a cylinder. Therefore, a cylinder is installed in the horizontal transparent section of a water tunnel. Particle image velocimetry technique is used to measure flow velocity downstream of the cylinder under no-ventilation condition. Air is injected into water flows through a flow passage inside the cylinder. High-speed photography, in association with a LED light source, is utilized to capture consecutive images of moving bubbles downstream of the cylinder. With the research techniques, it is expected to obtain primary bubble parameters such as velocity, Sauter mean diameter and volume fraction. Furthermore, the relationship between carrier flow characteristics and bubbly flow pattern is expected to be established.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Brennen CE. Cavitation and bubble dynamics. Oxford: Oxford University Press; 1995.

Lee SJ, Kawakami E, Arndt REA. Measurements in the wake of a ventilated hydrofoil. In: ASME 2013 fluids engineering division summer meeting, Nevada, USA. 2013 July 7–11.

Xiang M, Cheung SPP, Yeoh GH, Zhang WH, Tu JY. On the numerical study of bubbly flow created by ventilated cavity in vertical pipe. Int J Multiph Flow. 2011;37:756–68.

Kawakami W, Arndt REA. Investigation of the behavior of ventilated supercavities. J Fluids Eng. 2011;133(9):091305.

Varaksin AY. Fluid dynamics and thermal physics of two-phase flows: problems and achievements. High Temp. 2013;51(3):377–407.

Akbar MHM, Hayashi K, Lucas D, Akio Tomiyama A. Effects of inlet condition on flow structure of bubbly flow in a rectangular column. Chem Eng Sci. 2013;104:166–176.

Colombet D, Legendre D, Cockx A, Guiraud P, Risso F, Daniel C, Galinat S. Experimental study of mass transfer in a dense bubble warm. Chem Eng Sci. 2011;66:3432–3440.

Hosokawa S, Tomiyama A. Bubble-induced pseudo turbulence in laminar pipe flows. Int J Heat Fluid Flow. 2013;40:97–105.

Karn A, Shao S, Arndt REA, Hong J. Bubble coalescence and breakup in turbulent bubbly wake of a ventilated hydrofoil. Exp Thermal Fluid Sci. 2016;70:397–407.

Batchelor GK. Pressure fluctuations in isotropic turbulence. Math Proc Cambridge Philos Soc. 1951;47:359–374.

Hinze JO. Fundamentals of the hydrodynamic mechanism of splitting in dispersion processes. AIChE J. 1955;1(3):289–295.

Rigby GD, Evans G, Jameson GJ. Bubble breakup from ventilated cavities in multiphase reactors. Chem Eng Sci. 1997;52(21–22):3677–3684.

Kelbaliev GI. Mass transfer between a drop or gas bubble and an isotropic turbulent flow. Theor Found Chem Eng. 2012;46(5):477–485.

Shawkat ME, Ching C, Shoukri M. On the liquid turbulence energy spectra in two-phase bubbly flow in a large diameter vertical pipe. Int J Multiph Flow. 2007;33(3):300–316.

Gore RA, Crowe CT. Effect of particle size on modulating turbulent intensity. Int J Multiph Flow. 1989;15(2):279–285.

Crowe CT. On models for turbulence modulation in fluid–particle flows. Int J Multiph Flow. 2000;26(5):719–727.

Hibiki T, Ishii M. Experimental study on interfacial area transport in bubbly two-phase flows. Int J Heat Mass Transf. 1999;42(16):3019–3035.

Michiyoshi I, Serizawa A. Turbulence in two-phase bubbly flow. Nucl Eng Des. 1986;95(86):253–267.

Yeoh GH, Cheung SCP, Tu JY. On the prediction of the phase distribution of bubbly flow in a horizontal pipe. Chem Eng Res Des. 2012;90(1):40–51.

Liu TJ, Bankoff SG. Structure of air–water bubbly flow in a vertical pipe I. liquid mean velocity and turbulence measurements. Int J Heat Mass Transf. 1993;36(4):1049–1060.

Kataoka I, Serizawa A, Besnard DC. Prediction of turbulence suppression and turbulence modeling in bubbly two-phase flow. Nucl Eng Des. 1993;141(1–2):145–158.

Fujiwara A, Minato D, Hishida K. Effect of bubble diameter on modification of turbulence in an upward pipe flow. Int J Heat Fluid Flow. 2004;25(3):481–488.

Aloui F, Doubliez L, Legrand J, Souhar M. Bubbly flow in an axisymmetric sudden expansion: Pressure drop, void fraction, wall shear stress, bubble velocities and sizes. Exp Thermal Fluid Sci. 1999;19(2):118–130.

Sungkorn R, Derksen JJ, Khinast JG. Modeling of turbulent gas–liquid bubbly flows using stochastic Lagrangian model and lattice-Boltzmann scheme. Chem Eng Sci. 2011;66(12):2745–2757.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2019 Science Press, Beijing and Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Kang, C., Liu, H., Mao, N., Zhang, Y. (2019). Wake Flow of the Ventilation Cylinder. In: Methods for Solving Complex Problems in Fluids Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-2649-3_5

Download citation

DOI: https://doi.org/10.1007/978-981-13-2649-3_5

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-2648-6

Online ISBN: 978-981-13-2649-3

eBook Packages: EngineeringEngineering (R0)