Abstract

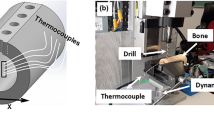

Many researches on drilling force and temperature have been done with the aim to reduce the labour intensiveness of surgery, avoid unnecessary damage and improve drilling quality. However, there has not been a systematic study of mid- and high-speed drilling under dry and physiological conditions(injection of saline). Furthermore, there is no consensus on optimal drilling parameters. To study these parameters under dry and physiological drilling conditions, pig humerus bones are drilled with medical twist drills operated using a wide range of drilling speeds and feed rates. Drilling force and temperature are measured using a YDZ-II01W dynamometer and a NEC TVS-500EX thermal infrared imager, respectively, to evaluate internal bone damage. To evaluate drilling quality, bone debris and hole morphology are observed by SEM(scanning electron microscopy). Changes in drilling force and temperature give similar results during drilling such that the value of each parameter peaks just before the drill penetrates through the osteon of the compact bone into the trabeculae of the spongy bone. Drilling temperatures under physiological conditions are much lower than those observed under dry conditions, while a larger drilling force occurs under physiological conditions than dry conditions. Drilling speed and feed rate have a significant influence on drilling force, temperature, bone debris and hole morphology. The investigation of the effect of drilling force and temperature on internal bone damage reveals that a drilling speed of 4500 r/min and a feed rate of 50 mm/min are recommended for bone drilling under physiological conditions. Drilling quality peaks under these optimal parameter conditions. This paper proposes the optimal drilling parameters under mid- and high-speed surgical drilling, considering internal bone damage and drilling quality, which can be looked as a reference for surgeons performing orthopedic operations.

Similar content being viewed by others

References

AUGUSTIN G, ZIGMAN T, DAVILA S, et al. Cortical bone drilling and thermal osteonecrosis[J]. Clinical Biomechanics, 2012, 27(4): 313–325.

FARNWORTH G H, BURTON J A. Optimization of drill geometry for orthopaedic surgery[C]//Proceedings of the 14th International Conference on Machine Tool Design and Research Conference, Manchester, England, 1974: 227–233.

STEIN J M, DORNFELD D A. Burr formation in drilling miniature holes[J]. Cirp Ann-Manuf Techn, 1997, 46: 63–66.

ONG F R, BOUAZZA-MAROUF K. The detection of drill-bit break-through for the enhancement of safety in mechatronic assisted orthopaedic drilling[J]. Mechatronics, 1999, 9: 565–588.

JANTUNEN E. A summary of methods applied to tool condition monitoring in drilling[J]. International Journal of Machine Tools and Manufacture, 2002, 42: 997–1010.

BRETT P N, BAKER D A, TAYLOR R, et al. Controlling the penetration of flexible bone tissue using the stapedotomy microdrill[C]//Proceedings of the Institution of Mechanical Engineers, Part I: Journal of Systems and Control Engineering, 2004, 218: 343–351.

KENDOFF D, CITAK M, GARDNER M J, et al. Improved accuracy of navigated drilling using a drill alignment device[J]. Journal of Orthopaedic Research, 2007, 25: 951–957.

FUCHSBERGER A. The damaging temperature at the machining of bone[J]. Unfallchirurgie, 1988, 14(4): 173–183.

BACHUS K N, RONDINA M T, HUTCHINSON D T. The effects of drilling force on cortical temperatures and their duration: an in vitro study[J]. Medical Engineering & Physics, 2000, 22(10): 685–691.

KREITH F. The CRC handbook of thermal engineering[M]. Boca Raton: CRC Press LLC, 2000.

AUGUSTIN G, DAVILA S, UDILHAK T, et al. Determination of spatial distribution of increase in bone temperature during drilling by infrared thermography: preliminary report[J]. Archives of Orthopaedic and Trauma Surgery, 2009, 129(5): 703–709.

SAHA S, PAL S, ALBRIGHT J A. Surgical drilling: design and performance of an improved drill[J]. Journal of Biomechanical Engineering, 1982, 104(3): 245–252.

DAVIDSON S R H, JAMES D F. Drilling in bone: Modeling heat generation and temperature distribution[J]. Journal of Biomechanical Engineering, 2003, 125(3): 305–314.

PANDEY R K, PANDA S S. Drilling of bone: A comprehensive review[J]. Journal of Clinical Orthopaedics and Trauma, 2013, 4(1): 15–30.

UDILJAK T, CIGLAR D, SKORIC S. Investigation into Bone Drilling and Thermal Bone Necrosis[J]. Advances in Production Engineering & Management, 2007, 3: 103–112.

SUI J, SUGITA N, ISHII K, et al. Force analysis of orthogonal cutting of bovine cortical bone[J]. Machining Science and Technology: An International Journal, 2013, 17: 637–649.

YANG Yixin, WANG Chengyong, QIN Zhe, et al. Drilling force and temperature of bone by surgical drill[J]. Advanced Materials Research, 2010, 126–128: 779–784.

HILLERY M T, SHUAIB I. Temperature effects in the drilling of human and bovine bone[J]. Journal of Materials Processing Technology, 1999, 92–93: 302–308.

THOMPSON H C. Effect of drilling into bone[J]. J. Oral. Surg., 1958, 16: 22–30.

BRISMAN D L. The effect of speed, pressure, and time on bone temperature during the drilling of implant sites[J]. Int. J. Oral. Maxillofac., 1996, 11(1): 35–37.

TOEWS A R, BAILEY J V, TOWNSEND H G, et al. Effect of feed rate and drill speed on temperatures in equine cortical bone[J]. Am. J. Vet. Res., 1999, 60(8): 942–944.

NAM O, YU W, CHOI M Y, et al. Monitoring of bone temperature during osseous preparation for orthodontic micro-screw implants: effect of motor speed and ressure[J]. Key Engineering Materials, 2006, 321–323: 1044–1047.

AUGUSTIN G, DAVILA S, MIHOCI K, et al. Thermal osteonecrosis and bone drilling parameters revisited[J]. Arch. Orthop. Trauma Surg., 2008, 128: 71–77.

KARACA F, AKSAKAL B, KOM M. Influence of orthopaedic drilling parameters on temperature and histopathology of bovine tibia: An in vitro study[J]. Medical Engineering & Physics, 2011, 33: 1221–1227.

LEE J, RABIN Y, OZDOGANLAR O B. A new thermal model for bone drilling with application to orthopaedic surgery[J]. Medical Engineering & Physics, 2011, 33: 1234–1244.

SHARAWY M, MISCH C E, WELLER N, et al. Heat generation during implant drilling: the significance of motor speed[J]. Journal of Oral and Maxillofacial Surgery, 2002, 60(10): 1160–1169.

TU Yuankun, HONG Youyao, CHEN Yungchuan. Finite element modeling of Kirschner pin and bone thermal contact during drilling[J]. Life Sci. J., 2009, 6(4): 23–27.

MATTHEWS L S, HIRSCH C. Temperature measured in human cortical bone when drilling[J]. J. Bone Joint Surg. Am., 1972, 54: 297–308.

LEE J, GOZEN B A, OZDOGANLAR O B. Modeling and experimentation of bone drilling forces[J]. Journal of Biomechanics, 2012, 45: 1076–1083.

LAVELLE C, WEDGWOOD D. Effect of internal irrigation on frictional heat generated from bone drilling[J]. J. Oral. Surg., 1980, 38: 499–503.

GIRAUD J-Y, VILLEMIN S, DARMANA R, et al. Bone cutting[J]. Clinical Physics and Phusiological Measurement, 1991, 12(1): 1–19.

ERCOLI C, FUNKENBUSCH P D, LEE H J, et al. The influence of drill wear on cutting efficiency and heat production during osteotomy preparation for dental implants: a study of drill durability[J]. The International Journal of Oral & Maxillofacial Implants, 2004, 19: 335–349.

KARMANI S. The thermal properties of bone and the effects of surgical intervention[J]. Current Orthopaedics, 2006, 20: 52–58.

BERTOLLO N, MILNE H R M, ELLIS L P, et al. A comparison of the thermal properties of 2- and 3-fluted drills and the effects on bone cell viability and screw pull-out strength in an ovine model[J]. Clinical Biomechanics, 2010, 25: 613–617.

AERSSENS J, BOONEN S, LOWET G, et al. Interspecies differences in bone composition, density and quality: potential implications for in vivo bone[J]. Endocrinology, 1998, 139: 663–670.

ALLOTTA B, BELMONTE F, BOSIO L, et al. Study on a mechatronic tool for drilling in the osteosynthesis of long bones: Tool/bone interaction, modeling and experiments[J]. Mechatronics, 1996, 6: 447–459.

ONG F R, BOUAZZA-MAROUF K. Evaluation of bone strength: correlation between measurements of bone mineral density and drilling force[J]. Proc. Inst. Mech. Eng. H, 2000, 214(4): 385–399.

YANG Yixin. Study on drilling performance of new surgical drill[D]. Guangzhou: Guangdong University of Technology, 2010. (in Chinese)

QUAN Yanming, ZHAO Jing, LI Yiping. Surface emissivity calibration for metal cutting tool and workpiece materials with infrared imager[J]. Journal of Mechanical Engineering, 2009, 45(12): 182–186. (in Chinese)

LEACH E H, PETERS R A, ROSSITER R J. Experimental thermal burns, especially the moderate temperature burn[J]. Q. J. Exp. Physiol., 1943, 32: 67.

ERIKSSON R A, ALBREKTSSON T. Temperature threshold levels for heat induced bone tissue injury: A vital microscopic study in rabbit[J]. J. Prosth Dent, 1983, 50: 101–107.

KIM P I, KIM Y S, JANG K S, et al. A study on the temperature changes of tissues during implant site preparation[J]. J. Korean Acad Prosthodont, 2002, 40(1): 1–8.

LEE J, OZDOGANLAR O B, RABIN Y. An experimental investigation on thermal exposure during bone drilling[J]. Medical Engineering & Physics, 2012, 34(10): 1510–1520.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by Foundation for High-level Talents in Higher Education of Guangdong, China (Grant No. 501111018) and Panyu District Science and Technology Program of China (Grant No. 2009-Z-53-1)

XU Linlin, born in 1986, is currently an engineer at Guangzhou Aquila Precise Tools Ltd, China. She received her PhD degree from Guangdong University of Technology, China, in 2014. Her research interests include advanced high-speed machining technology and new medical tool performance.

WANG Chengyong, born in 1964, is currently a professor at Guangdong University of Technology, China.

JIANG Min, born in 1987, is currently a master candidate at Guangdong University of Technology, China.

HE Huiyu, born in 1989, is currently a master candidate at Guangdong University of Technology, China.

SONG Yuexian, born in 1961, is currently a senior engineer at Guangdong University of Technology, China.

CHEN Hanyuan, born in 1947, is currently a senior engineer at Guangzhou Aquila Precise Tools Ltd, China.

SHEN Jingnan, born in 1959, is currently a professor at The First Affiliated Hospital, Sun Yat-sen University, China.

ZHANG Jiayong, born in 1968, is currently a director at National Engineering Research Center for Healthcare Devices, China.

Rights and permissions

About this article

Cite this article

Xu, L., Wang, C., Jiang, M. et al. Drilling force and temperature of bone under dry and physiological drilling conditions. Chin. J. Mech. Eng. 27, 1240–1248 (2014). https://doi.org/10.3901/CJME.2014.0912.151

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3901/CJME.2014.0912.151