Abstract

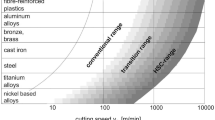

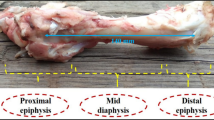

Currently, in the world of orthopedic surgeries, bone drilling is prevalent to hold broken bones and for bone implantation. Increase of bone temperature higher than 47 °C leads to a notorious phenomenon named thermal necrosis, which eventuates in cellular death of the bone tissue. Consequently, there is a chance for a loose implant after the operation. In this paper, for the first time, a 3D thermo-mechanical finite element (FE) model of a high-speed bone drilling process was introduced to study process force and temperature. Then comparing experimental results with numerical ones, the influence of the rotational speed and feed rate on both process force and the temperature was investigated. This study revealed that in high-speed drilling of the bone with a raise in rotational speed, due to different chip deformation and reduced chip thickness, both process force and temperature reduce remarkably. According to experimental and numerical findings, the optimum bone drilling setting was achieved with a tool diameter of 2 mm, the rotational speed of 12,000 rpm, and feed rate of 50 mm/min in which force and temperature were 14.11 N and 32.45 °C, respectively. The findings of this study can be an excellent help for robotic surgeries in order to decrease drilling force and temperature and ultimately squeezing of the recovery period.

Similar content being viewed by others

References

Hillery MT, Shuaib I (1999) Temperature effects in the drilling of human and bovine bone. J Mater Process Technol 92:302–308

Sui J et al (2014) Mechanistic modeling of bone-drilling process with experimental validation. J Mater Process Technol 214(4):1018–1026

Eriksson R, Albrektsson T (1984) The effect of heat on bone regeneration: an experimental study in the rabbit using the bone growth chamber. J Oral Maxillofac Surg 42(11):705–711

Moritz AR, Henriques F Jr (1947) Studies of thermal injury: II. The relative importance of time and surface temperature in the causation of cutaneous burns. Am J Pathol 23(5):695

Pandey RK, Panda SS (2015) Optimization of multiple quality characteristics in bone drilling using grey relational analysis. J Orthop 12(1):39–45

Reingewirtz Y, Szmukler-Moncler S, Senger B (1997) Influence of different parameters on bone heating and drilling time in implantology. Clin Oral Implant Res 8(3):189–197

Abouzgia MB, James DF (1997) Temperature rise during drilling through bone. Int. J Oral Maxillofac Implants, 12(3).

Heydari H et al (2018) Analytical and experimental study of effective parameters on process temperature during cortical bone drilling. Proc Inst Mech Eng [H] 232(9):871–883

Singh G et al (2016) Optimization of process parameters for drilled hole quality characteristics during cortical bone drilling using Taguchi method. J Mech Behav Biomed Mater 62:355–365

Chen S et al (2019) Mechanism of chip formation in ultrasonic vibration drilling and experimental research. Proc Inst Mech Eng Part C J Mech Eng Sci 233(15):5214–5226

Sarparast M et al (2019) Modelling and optimisation of temperature and force behaviour in high-speed bone drilling. Biotechnol Biotechnol Equip 33(1):1616–1625

Shakouri E, Sadeghi M, Maerefat M (2013) Experimental investigation of thermal necrosis in conventional and high speed drilling of Bone. Modares Mech Eng 13(10):105–117

Tahmasbi V, Ghoreishi M, Zolfaghari M (2017) Investigation, sensitivity analysis, and multi-objective optimization of effective parameters on temperature and force in robotic drilling cortical bone. Proc Inst Mech Eng [H] 231(11):1012–1024

Tahmasbi V, Ghoreishi M, Zolfaghari M (2018) Sensitivity analysis of temperature and force in robotic bone drilling process using Sobol statistical method. Biotechnol Biotechnol Equip 32(1):130–141

Gok K et al (2015) Development of a new driller system to prevent the osteonecrosis in orthopedic surgery applications. J Braz Soc Mech Sci Eng 37(2):549–558

Iyer S, Weiss C, Mehta A (1997) Effects of drill speed on heat production and the rate and quality of bone formation in dental implant osteotomies. Part I: Relationship between drill speed and heat production. Int. J. Prosthodont, 10(5).

Boyne PJ (1966) Histologic response of bone to sectioning by high-speed rotary instruments. J Dent Res 45(2):270–276

Moss RW (1964) Histopathologic reaction of bone to surgical cutting. Oral Surg Oral Med Oral Pathol 17(3):405–414

Jacobs C et al (1974) A study of the bone machining process—orthogonal cutting. J Biomech 7(2):131–136

Alam K, Mitrofanov A, Silberschmidt VV (2009) Finite element analysis of forces of plane cutting of cortical bone. Comput Mater Sci 46(3):738–743

Nordin M, Frankel VH (2001) Basic biomechanics of the musculoskeletal system. Lippincott Williams & Wilkins.

O'Mahony AM, Williams JL, Spencer P (2001) Anisotropic elasticity of cortical and cancellous bone in the posterior mandible increases peri-implant stress and strain under oblique loading. Clin Oral Implant Res 12(6):648–657

Vercher A et al (2014) Homogenized stiffness matrices for mineralized collagen fibrils and lamellar bone using unit cell finite element models. Biomech Model Mechanobiol 13(2):437–449

Davidson SR, James DF (2003) Drilling in bone: modeling heat generation and temperature distribution. J Biomech Eng 125(3):305–314

Wang Y et al (2014) Experimental investigations and finite element simulation of cutting heat in vibrational and conventional drilling of cortical bone. Med Eng Phys 36(11):1408–1415

Tu Y-K et al (2013) Finite element simulations of bone temperature rise during bone drilling based on a bone analog. J Med Biol Eng 33(3):269–274

Sezek S, Aksakal B, Karaca F (2012) Influence of drill parameters on bone temperature and necrosis: a FEM modelling and in vitro experiments. Comput Mater Sci 60:13–18

Alam K, Khan M, Silberschmidt VV (2014) 3D finite-element modelling of drilling cortical bone: temperature analysis. J Med Biol Eng 34(6):618–623

Tu Y-K, Hong Y-Y, Chen Y-C (2009) Finite element modeling of kirschner pin and bone thermal contact during drilling. Life Sci J 6(4):23–27

Lughmani WA, Bouazza-Marouf K, Ashcroft I (2015) Drilling in cortical bone: a finite element model and experimental investigations. J Mech Behav Biomed Mater 42:32–42

Gok A, Gok K, Bilgin M (2015) Three-dimensional finite element model of the drilling process used for fixation of Salter-Harris type-3 fractures by using a K-wire. Mech Sci 6(2):147–154

Rosidi A, Ginta TL, Rani AMBA (2017) Optimization of bone drilling parameters using Taguchi method based on finite element analysis. In IOP conference series: materials science and engineering. IOP Publishing, Bristol

Fernandes M, Fonseca E, Natal R (2017) Assessment of different drill diameter on bone drilling process. J Mech Eng Biomech 1(6):135–141

Smith, M., ABAQUS/Standard user’s manual, version 6.9. 2009.

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest to the research, authorship, and/or publication of this article.

Additional information

Technical Editor: Adriano Almeida Gonçalves Siqueira.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sarparast, M., Ghoreishi, M., Jahangirpoor, T. et al. Experimental and finite element investigation of high-speed bone drilling: evaluation of force and temperature. J Braz. Soc. Mech. Sci. Eng. 42, 349 (2020). https://doi.org/10.1007/s40430-020-02436-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02436-w