Abstract

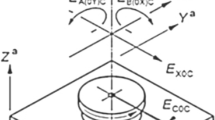

For smoother gear changes, the ends of the gear teeth are rounded in gearboxes. The rounding profile depends on the gear’s operating conditions. A cam has been designed for the manufacture of a nonstandard tooth-tip profile (120° facets) on a 5N530 machine tool. The profiling algorithm for the cam is described, and the coordinates of a random point on the cam profile are calculated in several examples. Some relations between the cam geometry and the geometry of the gear being machined are explained. The calculations largely employ MS Excel software, which requires practically no special skills. KOMPAS-3D software is used to formulate the design problem and for the design of the cam profile itself. The method proposed for cam design is simple and readily employed.

Similar content being viewed by others

REFERENCES

Osepchugov, V.V. and Frumkin, A.K., Avtomobil’. Analiz konstruktsii, elementy rascheta (Car. Analysis of Structures, Calculation Elements), Moscow: Mashinostroenie, 1989.

Dragunov, G.D., RF Patent RU2268162, 2006. https://findpatent.ru/patent/226/2268162.html2012-2020.

Tooth-Rounding Machines. https://tornus.ru/katalog/metallorezanie/zuboobrabatyivayushhie/zubozakruglyayushhie/. Accessed December 13, 2020.

Siemens Industry YW9325 with CNC Siemens 802D Product Catalog. https://uselogic.ru/catalogs/siemens-ca01/katalog-produktov-siemens-industry-39955/. Accessed December 15, 2020.

Tooth-Rounding Machines. Purchase. https://spb.stanok-kpo.ru/katalog/zuboobrabatyvayuschie/. Accessed December 13, 2020.

Tooth-Rounding Machines in Russia. https://flagma.ru/zubozakruglyayushchiy-stanok-so1399482-1.html/. Accessed November 16, 2020.

Vinarskii, M.S., Planirovanie eksperimenta v tekhnolo-gicheskikh issledovaniyakh (Planning the Experiment in Technological Research), Kiev: Tekhnika, 1975.

Kirilin, Yu.V., Ispytaniya i issledovaniya metallorezhu-shchikh stankov: Metodicheskie ukazaniya k laboratornym rabotam (Testing and Research of Metal-Cutting Machines: Methodological Instructions for Laboratory Work), Ul’yanovsk: Ul’yanovsk. Gos. Tekh. Univ., 2012.

Diagnostika tekhnologicheskoi sistemy “Stanok–prispo-soblenie–instrument–detal’”: Uchebnoe posobie (Diagnostics of the Technological System “Machine–Device–Tool–Part”: Manual), Gavrilin, A.N. and Moizes, B.B., Eds., Tomsk: Tomsk. Politekh. Univ., 2016.

Lyubomudrov, S.A., Khrustaleva, I.N., Tolstoles, A.A., and Maslakov, A.P., Improving the efficiency of technological preparation of single and small batch production based on simulation modeling, J. Min. Inst., 2019, vol. 240, pp. 669–677.

Pegashkin, V.F., Obrabotka zubchatykh koles: Uchebnoe posobie (Gear Wheel Processing: Manual), Nizhnii Tagil: Nizhnetagilsk. Tekhnol. Inst. Ural. Fed. Univ., 2016.

GOST (State Standard) 8-82: Metal-Cutting Machine Tools. General Requirements to Accuracy Tests, 1983.

GOST (State Standard) 19166-73: Gear Tooth Rounding Machines. Standarts oi Accuracy, 1975.

GOST (State Standard) 22267-76: Metal-cutting machine tools. Schemes and procedures of measuring geometrical parameters, 1978.

GOST (State Standard) 27.410-87: Industrial product dependability. Inspection methods of reliability indices and plans of check tests on reliability, 1989.

Metallorezhushchie stanki i avtomaty: Uchebnik dlya vuzov (Metal-Cutting Machines and Automatic Machines: Manual for Higher Education Institutions), Pronikov, A.S., Ed., Moscow: Mashinostroenie, 1981.

Gavrilin, A.N., Angatkina, O.O., and Rozhkov, P.S., Innovative design for optimization of productivity and accuracy of cutting operations with CNC machines, Kontrol’. Diagnostika, 2011, no. 2, pp. 52–55.

Rukovodstvo po ekspluatatsii stanka KSM-5530 (Operating Manual of the KSM-5530 Machine), St. Petersburg.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by B. Gilbert

About this article

Cite this article

Savinov, Z.S., Makarova, T.A. & Kozar’, I.I. Modernization of Tooth-Rounding Equipment in Gear Production. Russ. Engin. Res. 42, 258–261 (2022). https://doi.org/10.3103/S1068798X22030194

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X22030194