Abstract

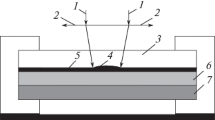

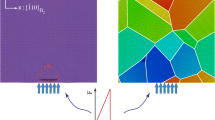

The laser shock peening of NiTi alloys with shape memory is investigated by means of dimensional analysis and finite-element simulation. The depth of the plastic zone is determined as a function of the peak pressure in the shock wave and the length of the laser pulse at different peak pressures.

Similar content being viewed by others

REFERENCES

Kazuhiro, O. and Clarence, W., Shape Memory Materials, Cambridge: Cambridge Univ. Press, 1999.

Sergueeva, A.V., Song, C., Valiev, R.Z., and Mukherjee, A.K., Structure and properties of amorphous and nanocrystalline NiTi prepared by severe plastic deformation and annealing, Mater. Sci. Eng., A, 2003, vol. 339, pp. 159–165.

Liao, Y., Ye, C., Lin, D., et al., Deformation induced martensite in NiTi and its shape memory effects generated by low temperature laser shock peening, J. Appl. Phys., 2012, vol. 112.

Sakhvadze, G.Zh., Sakhvadze, G.G., and Kavtara-dze, R.Z., Increasing the crack resistance of materials by means of laser shock processing, Russ. Eng. Res., 2021, vol. 41, no. 1, pp. 27–33. https://doi.org/10.3103/S1068798X21010202

Sakhvadze, G.Z. and Kikvidze, O.G., The role of laser shock processing treatment in the growth dynamics of fatigue cracks in specimens of Ti–6Al–4V titanium alloys damaged by foreign objects, J. Mach. Manuf. Reliab., 2020, vol. 49, no. 10, pp. 836–847.

Sakhvadze, G.Zh., Enhancement of material crack resistance using laser shock processing, J. Mach. Manuf. Reliab., 2020, vol. 49, no. 4, pp. 335–340. https://doi.org/10.3103/S1052618820040123

Sedov, L.I., Metody podobiya i razmernosti v mekhanike (Methods of Similarity and Dimension in Mechanics), Moscow: Nauka, 1977.

Meziere, Y.J.E., Millett, J.C.F., and Bourne, N.K., Equation of state and mechanical response of NiTi during one-dimensional shock loading, J. Appl. Phys., 2006, vol. 100.

Lubliner, J. and Auricchio, F., Generalized plasticity and shape-memory alloys, Int. J. Solids Struct., 2006, vol. 33, pp. 991–1003.

Ding, K., Three-dimensional dynamic finite element analysis of multiple laser shock peening processes, Surf. Eng., 2013, vol. 19, pp. 351–358.

Arif, A.F., Numerical prediction of plastic deformation and residual stresses induced by laser shock processing, J. Mater. Process. Technol., 2003, vol. 136, pp. 120–138.

Ballard, P., Fournier, J., and Fabbro, R., Residual stresses induced by laser-shocks, J. Phys. IV, 2001, vol. 1, pp. 487–494.

Wu, X.Q., Tan, Q.M., and Huang, C.G., Geometrical scaling law for laser shock peening, J. Appl. Phys. 2013, vol. 114.

Luo, K.Y., Lu, J.Z., Zhang, Y.K., et al., Effects of laser shock processing on mechanical properties and micro-structure of ANSI 304 austenitic stainless steel, Mater. Sci. Eng., A, 2011, vol. 528, pp. 4783–4788.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by B. Gilbert

About this article

Cite this article

Sakhvadze, G.Z., Sakhvadze, G.G., Kavtaradze, R.Z. et al. Dimensional Analysis in Laser Shock Peening of Titanium Alloys with Shape Memory. Russ. Engin. Res. 42, 125–131 (2022). https://doi.org/10.3103/S1068798X22020216

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X22020216