Abstract

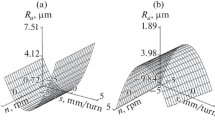

The influence of the cutting conditions on the surface roughness Ra is compared for parts produced by additive and traditional methods. The internal structure of parts produced by direct metal deposition (DMD) has a considerable influence on the surface quality.

Similar content being viewed by others

REFERENCES

Abbasov, A.E., Systemic research and forecasting using rapid prototyping technology, Inf.-Tekhnol. Vestn., 2015, no. 3 (5), pp. 3–14.

Aleksandrov, V.V., Aleksandrova, V.V., Zaitseva, A.A., and Khurs, S.P., Industrial 3D digital technology, Tr. S.-Peterb. Inst. Inf. Avtom., Ross. Akad. Nauk, 2010, no. 4 (15), pp. 85–92.

Litunov, S.N., Slobodnyuk, V.S., Mel’nikov, D.V., Review and analysis of additive technologies, Part 1, Omsk. Nauchn. Vestn., 2016, no. 1 (145), pp. 12–17.

Litunov, S.N., Slobodnyuk, V.S., Mel’nikov, D.V., et al., Review and analysis of additive technologies, Part 2, Omsk. Nauchn. Vestn., 2016, no. 5 (149), pp. 2–24.

Chemodurov, A.N., Application of additive technologies for the manufactoring of mechanical engineering products, Izv. Tul’sk. Gos. Univ., Tekh. Nauki, 2016, no. 8-2, pp. 210–216.

Rebrova, I.A., Planirovanie eksperimenta: Uchebnoe posobie (Experiment Planning: Manual), Omsk: Sib. Avtom.-Dorozhn. Inst., 2010.

Petkov, A.A., Ortogonal’noe tsentral’noe kompozitsionnoe planirovanie v tekhnike i elektrofizike vysokikh napryazhenii: Uchebno-metodicheskoe posobie (Orthogonal Central Compositional Planning in High Voltage Engineering and Electrophysics: Practical Manual), Kharkov: Nats. Tekh. Univ, KhPI, 2007.

Saprykina, N.A., Saprykin, A.A., and Arkhipova, D.A., Influence of layer-by-layer laser sintering on the quality of the sintered surface layer of products, Trudy VI Mezhdunarodnoi nauchno-prakticheskoi konferentsii “Innovatsionnye tekhnologii i ekonomika v mashinostroenii” (Proc. VI Int. Sci.-Pract. Conf. “Innovative Technologies and Economy in Machine Engineering”), Tomsk: Tomsk. Gos. Politekh. Univ., 2015, pp. 178–183.

Bezobrazov, Yu.A., Zlenko, M.A., Zotov, O.G., et al., Analysis of the structure of samples obtained by DMLS and SLM by rapid prototyping, Materialy 6-i Mezhdunarodnoi molodezhnoi nauchno-prakticheskoi konferentsii “Innovatsionnye tekhnologii v metallurgii i mashinostroenii” (Proc. Sixth Int. Youth Sci.-Pract. Conf. “Innovative Technologies in Metallurgy and Machine Engineering”), Yekaterinburg: Ural. Gos. Univ., 2013, pp. 154–157.

Funding

Financial support was provided by the Russian Ministry of Science and Higher Education (project FSNM-2020-0028).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by B. Gilbert

About this article

Cite this article

Muratov, K.R., Gashev, E.A., Ablyaz, T.R. et al. Influence of Cutting Conditions on the Surface Roughness of Titanium-Alloy Parts Produced by Additive and Traditional Methods. Russ. Engin. Res. 41, 434–436 (2021). https://doi.org/10.3103/S1068798X21050129

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X21050129