Abstract

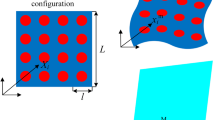

Linear homogenization is applied to cellular structures produced by selective laser melting (SLM). Samples of different materials with cells of different configurations are studied theoretically and experimentally. Their strain curves are compared with the results for bulk and beam models and with experimental data. After homogenization, the rigidity of the homogenized model differs by 5–10% from the beam model and by 8–16% from the bulk model.

Similar content being viewed by others

REFERENCES

Gibson, I., Rosen, D., and Stucker, B., Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, New York: Springer, 2015.

Kablov, E.N., Additive technologies as a keystone of the national technology initiative, Intell. Tekhnol., 2015, no. 2 (11), pp. 52–55.

Kablov, E.N., Innovative developments of the All-Russian Scientific Research Institute of Aviation Materials within the project “Strategic development of materials and technologies of their recycling until 2030,” Aviats. Mater. Tekhnol., 2015, no. 1 (34), pp. 3–33. https://doi.org/10.18577/2071-9140-2015-0-1-3-33

Kablov, E.N., Development of Russian national material science for space, Vestn. RFFI, 2017, no. 3, pp. 97–105.

Vostrikov, A.V. and Sukhov, D.I., Production of pellets for additive technologies by PREP method: current status and prospective development, Tr. Vseross. Nauchno-Issled. Inst. Aviats. Mater., 2016, no. 8, art. 3. http://www.viam-works.ru. Accessed June 15, 2019.https://doi.org/10.18577/2307-6046-2016-0-8-3-3

Kablov, E.N., The materials as a key problem, in Tendentsii i orientiry innovatsionnogo razvitiya Rossii (Trends and Benchmarks of Innovative Development in Russia), Moscow: Vseross. Nauchno-Issled. Inst. Aviats. Mater., 2015, pp. 458–464.

Gibson, L.J. and Ashby, M.F., Cellular Solids: Structure and Properties, Cambridge: Cambridge Univ. Press, 1999.

Sukhov, D.I., Mazalov, P.B., Nerush, S.V., and Khodyrev, N.A., Influence of the parameters of selective laser sintering on the porosity degree in the synthesized material of corrosion-resistant steel, Tr. Vseross. Nauchno-Issled. Inst. Aviats. Mater., 2017, no. 8 (56), art. 4. http://www.viam-works.ru. Accessed June 15, 2019.https://doi.org/10.18577/2307-6046-2017-0-8-4-4

Rehme, O. and Emmelmann, C., Rapid manufacturing of lattice structures with selective laser melting, Proc. SPIE, 2006, vol. 6107, pp. 61070K-1–61070K-12. https://doi.org/10.1117/12.645848

Hill, R., Elastic properties of reinforced solids: some theoretical principles, J. Mech. Phys. Solids, 1963, vol. 11, no. 5, pp. 357–372. https://doi.org/10.1016/0022-5096(63)90036-x

Huet, C., Application of variational concepts to size effects in elastic heterogeneous bodies, J. Mech. Phys. Solids, 1990, vol. 38, pp. 813–841. https://doi.org/10.1016/0022-5096(90)90041-2

Sab, K. On the homogenization and the simulation of random materials, Eur. J. Mech., 1992, vol. 11, pp. 585–607.

Sun, C.T. and Vaidya, R.S., Prediction of composite properties from a representative volume element, Compos. Sci. Technol., 1996, vol. 56, pp. 171–179. https://doi.org/10.1016/0266-3538(95)00141-7

Christensen, R.M., Mechanics of Composite Materials, Chichester: Wiley, 1979.

Nasedkin, A.V. and Shevtsova, M.S., Effective moduli simulation for various types of porous piezoceramic materials, Vestn. Donsk. Gos. Tekh. Univ., 2013, nos. 3–4, pp. 72–73.

Annin, B.D. and Ostrosablin, N.I., Anisotropy of elastic properties of materials, J. Appl. Mech. Tech. Phys., 2008, vol. 49, no. 6, pp. 998–1014.

Ivanov, M.L., Analysis and modeling of the mechanical behavior of brickwork as an elastic-brittle system, Trudy Mezhdunarodnoi mauchnoi konferentsii “Tekhnicheskie nauki: problemy i perspektivy” (Proc. Int. Sci. Conf. “Technical Sciences: Problems and Prospects”), St. Petersburg: Renome, 2011, pp. 58–62. https://moluch.ru/conf/tech/archive/2/146/. Accessed June 15, 2019.

Evgenov, A.G., Gorbovets, M.A., and Prager, S.M., Structure and mechanical properties of VZh159 and EP648 heat-resistant alloys obtained by selective laser sintering, Aviats. Mater. Tekhnol., 2016, suppl. 1, pp. 8–15. https://doi.org/10.18577/2071-9140-2016-0-S1-8-15

Yakovlev, N.O., Grinevich, D.V., and Mazalov, P.B., Mathematical modeling of the stress-strain state of compressed mesh construction synthesized by selective laser sintering, Vestn. MGTU N. E. Baumana, Ser. Estestv. Nauki, 2018, no. 6 (81), pp. 113–127. https://doi.org/10.18698/1812-3368-2018-6-113-127

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by B. Gilbert

About this article

Cite this article

Grinevich, D.V., Yakovlev, N.O. & Mazalov, P.B. Linear Homogenization in the Analysis of Cellular Structures Produced by Additive Technology. Russ. Engin. Res. 41, 423–427 (2021). https://doi.org/10.3103/S1068798X2105004X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X2105004X