Abstract

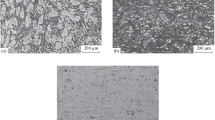

Friction stir welding of butt joints in aluminum alloys is considered. Experiments show that, with disruption of the welding temperature and time, defects localized at the boundary of the weld seam are observed: specifically, gaps due to the differential deformation of the seam and the matrix.

Similar content being viewed by others

REFERENCES

Drits, A.M., Ovchinnikov, V.V., and Rastopchin, R.N., Technological properties of sheets of welded aluminum alloy 1565ch for the production of tanks, Tekhnol. Legk. Splavov, 2012, no. 3, pp. 20–29.

Pavlova, V.I., Zykov, S.A., and Osokin, E.P., The influence of structural and technological factors of welding on the properties of welded joints from aluminum-magnesium alloys at cryogenic temperature, Vopr. Materialoved., 2014, no. 2 (78), pp. 138–154.

Anikina, V.I., Gil’manshina, T.R., and Baranov, V.N., Struktura i svoistva alyuminievo-magnievykh splavov: monografiya (The Structure and Properties of Aluminum-Magnesium Alloys: Monograph), Krasnoyarsk: Sib. Fed. Univ., 2012.

Drits, A.M. and Ovchinnikov, V.V., Svarka alyuminievykh plavov: Monografiya (Welding of Aluminum Alloys: Monograph), Moscow: Ruda i Metally, 2017.

Lukin, V.I., Ospennikova, O.G., Ioda, E.N., and Panteleev, M.D., Welding of aluminum alloys for aerospace industry, Svarka Diagn., 2013, no. 2, pp. 47–51.

Ishchenko, A.Ya., Welding of aluminum alloys: research work performed at the Paton Institute of Electric Welding), Avtom. Svarka, 2007, no. 11, pp. 10–13.

Ovchinnikov, V.V., Porosity during welding of aluminum alloys, Zagotovit. Proizvod. Mashinostr., 2008, no. 1, pp. 12–16.

Ovchinnikov, V.V. and Drits, A.M., Properties of joints of sheets from aluminum alloys performed by friction stir welding, Zagotovit. Proizvod. Mashinostr., 2015, no. 10, pp. 7–15.

Filippov, A.V., Tarasov, S.Yu., Kolubaev, E.A., and Rubtsov, V.E., Analysis of defects in the form of smoothed poor welding fusion after friction stir welding, Fundam. Issled., 2015, no. 6, pp. 296–310.

Frolov, V.A., Konkevich, V.Yu., Predko, P.Yu., and Belotserkovets, V.V., Friction stir welding of heat-hardened alloy B95 of the Al–Zn–Mg–Cu system, Svar. Proizvod., 2013, no. 3, pp. 21–26.

Poklyatskii, A.G., Typical defects in friction stir welding of thin sheet aluminum alloys and the main reasons of their formation, Avtom. Svarka, 2008, no. 6, pp. 48–52.

Hirata, T., Ogiri, T., Hagino, H., Tanaka, T., and Chung, Y., Influence of friction stir welding parameters on grain size and formability in 5083 aluminum alloy, Mater. Sci. Eng., A, 2007, vol. 456, pp. 344–349.

Chen, H.B., Yan, K., Chen, S.B., Jiang, C.Y., and Zhao, Y., The investigation of typical welding defects for 5456 aluminum alloy friction stir welds, Mater. Sci. Eng., A, 2006, vol. 433, pp. 64–69.

Ovchinnikov, V.V., Drits, A.M., and Malov, D.V., Mechanical properties of welded joints of 1565chM and 1460T1 alloys in various combinations obtained by friction stir welding, Zagotovit. Proizvod. Mashinostr., 2015, no. 6, pp. 11–17.

MI 2083-90. Rekomendatsiya. Gosudarstvennaya sistema obespecheniya edinstva izmerenii. Izmereniya kosvennye. Opredelenie rezul’tatov izmerenii i otsenivanie ikh pogreshnostei (MI 2083-90. Recommendations. State System for Ensuring Uniformity of Measurements. Indirect Measurements. Determination of Measurement Results and Estimation of Their Errors), Moscow: Izd. Standartov, 1991.

Funding

This work was supported by the Russian Foundation for Basic Research, project no. contract 19-33-90272.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by B. Gilbert

About this article

Cite this article

Feofanov, A.N., Ovchinnikov, V.V. & Gubin, A.M. Mechanical Properties of Joints in Friction Stir Welding of Aluminum Alloys. Russ. Engin. Res. 40, 916–921 (2020). https://doi.org/10.3103/S1068798X20110088

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X20110088