Abstract

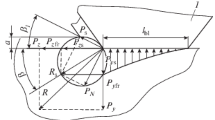

The removal of metal during reverse motion of the grinding wheel at extreme cross sections of holes in the workpiece during internal grinding is considered. In a single double pass of the wheel, the vibration of the contact area and the cutting forces are found to be significantly different in reverse motion within input and output holes. That disrupts the stability of metal removal and the machining precision over the length of the hole being machined. Approaches to the modeling of internal grinding with reverse motion of the grinding wheel are considered.

Similar content being viewed by others

References

Saikin, S.S., Salov, P.M., and Vinogradova, T.G., Determination of the circle overrun with internal grinding, Trudy nauchno-prakticheskoi konferentsii “Innovatsii v obrazovatel’nom protsesse” (Proc. Sci.-Pract. Conf. “Innovations in Education Process”), Cheboksary: Cheboksarsk. Fil., Mosk. Gos. Obl. Univ., 2010, no. 8, pp. 85–87.

Novoselov, Yu.K., Dinamika formoobrazovaniya poverkhnostei pri abrazivnoi obrabotke (Dynamics of Surface Abrasive Shaping), Sevastopol: Sevast. Nats. Tekh. Univ., 2012.

Pereverzev, P.P. and Akintseva, A.V., Model of formation of processing errors intragrinding, Russ. Eng. Res., 2016, vol. 36, no. 12, pp. 1048–1053.

Pereverzev, P.P. and Popova, A.V., Analytical modeling of the relationship the cutting force at internal grinding with the basic technological factors, Metalloobrabotka, 2013, no. 3, pp. 24–30.

Pereverzev, P.P. and Akintseva, A.V., Modeling of metal removal during an internal grinding in view of kinematics cutting features, Russ. Eng. Res., 2016, vol. 36, no. 10, pp. 888–893.

Pereverzev, P.P. and Akintseva, A.V., Modeling of limits by the accuracy of treatment in the engineering of optimal cycles of internal grinding, Vestn. Yuzh.-Ural. Gos. Univ., Ser.: Mashinostr., 2016, no. 2, pp. 61–71.

Ardashev, D.V., Anel’chik, D.E., Butorin, G.I., et al., Rezhimy rezan’ya na raboty, vypolnyaemye na shlifoval’nykh i dovodochnykh stankakh s ruchnym upravleniem i poluavtomatakh (Cutting Regimes for Grinding and Finishing Machines with Manual and Semi-Automatic Control), Chelyabinsk: Atokso, 2007.

Spravochnik tekhnologa-mashinostroitelya (Handbook of Technologist-Machine Engineer), Malov, A.N., Ed., Moscow: Mashinostroenie, 1972, vol.2.

Pereverzev, P.P. and Akintseva, A.V., Modeling and optimization of internal grinding cycles at the automated machine-building production, Vestn. Yuzh.-Ural. Gos. Univ., Ser.: Mashinostr., 2016, no. 3, pp. 44–53.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © P.P. Pereverzev, A.V. Akintseva, 2017, published in STIN, 2017, No. 9, pp. 29–33.

About this article

Cite this article

Pereverzev, P.P., Akintseva, A.V. Modelling of Metal Removal in Reverse Zones in the Process of Internal Grinding. Russ. Engin. Res. 38, 229–234 (2018). https://doi.org/10.3103/S1068798X18030152

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068798X18030152