Abstract—

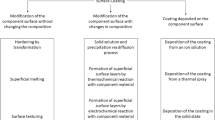

The paper proposes using charts of the expected abrasive wear of the soil-cutting part’s friction surface that characterize the intensity of wear at various points on the friction surface moving in the soil environment [1]. The obtained abrasive wear charts provided characteristics of friction surfaces within the boundaries of a more or less expected abrasive wear intensity. Then, considering the different wear intensity of the friction surfaces at different points, hardening by the electrospark method was conducted using thermally pre-treated gray cast iron. The hardening consisted in quenching at temperatures of 750–1050°C, followed by water cooling, or annealing at a temperature of 900°C for 1 h. These pre-steps made it possible to form a wear-resistant layer in several passes, while the structure of the cast iron and the base metal did not change. The physicomechanical properties and structures of the hardened layer including gray cast iron were studied. After tempering at a temperature of 300°C, its hardness increased up to HRC 50–55 without subsequent formation of quenching cracks. The best gray cast iron heat treatment method is hardening at a temperature of 900°C followed by water cooling. The hardness of the deposited layer was higher (4800–5000 MPa) than that of the base metal (2300–2400 MPa), and no weakening of the base metal was observed. According to the results of testing the hardened products, heat-treated gray cast iron can be recommended for use as a strengthening material, since the coating thickness does not lead to changes in the initial geometric dimensions of a soil-cutting tool using differentiated surfacing based on abrasive wear charts. The practical application of the proposed hardening process is recommended for plowshares, cultivator shares, and ripper chisels, as well as for blades of soil-cultivating machines.

Similar content being viewed by others

REFERENCES

Mialenko, V.I., Maps of abrasive wear of the friction surface of a soil-cutting part, Frict. Wear, 2020, vol. 41, no. 1, pp. 120–124.

Sankina, O.V., Increasing the wear resistance of tools of tillage machines, Dostizh. Nauki Tekh., 2019, vol. 33, no. 8, pp. 77–80.

Panov, I.M. and Vetokhin, V.I., Fizicheskie osnovy mekhaniki pochv (Physical Foundations of Soil Mechanics), Kiev: Phoenix, 2008.

Seernev, M.M., Podlekarev, N.N., Sokhadze, V.Sh., and Kitikov, V.O., Iznos i korroziya sel’skokhozyaistvennykh mashin (Wear and Corrosion of Agricultural Machines), Severnev, M.M., Ed., Minsk: Belarus. Navuka, 2011.

Goryacheva, I.G., Mekhanika friktsionnogo vzaimodeistviya (Mechanics of Frictional Interaction), Moscow: Nauka, 2001.

Chichinadze, A.V., Brown, E.D., Boucher, N.A., Osnovy tribologii: Trenie, iznos, smazka (Fundamentals of Tribology: Friction, Wear, Lubrication), Moscow: Mashinostroenie, 2001.

Mialenko, V.I., Marinov, N.A., Sankin, A.S., Bu-ziyan, O.N., and Ponurovsky, V.A., Installation for testing abrasive wear of working bodies of soil cultivating machines, Application no. 2016148356, RF Patent 2 649 241 C1, 2018.

Mialenko, V.I., Rudakova, S.I., and Badulin, R.S., Circular soil platform, Application no. 2 018 135 932, RF Patent No RU 2 704 290 C1, 2019.

Carcel-Carrasco, F.-J., Pascual-Guillamon, M., Salas-Vicente, F., et al., Influence of heat treatment in the microstructure of a joint of nodular graphite cast iron when using the tungsten inert gas welding process with perlitic grey cast iron rods as filler material, Metals, 2019, vol. 9, no. 1, p. 48

Saraev, Y., Gladkovsky, S., Lepikhin, S., Kamantsev, I., Lunev, A., and Perovskaya, M., Investigation of the influence of energy parameter of the covered-electrode welding on the impact strength characteristics and cracking resistance of the welded joints obtained, Obrab. Met., 2018, vol. 20, no. 2, pp. 100–115.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by S. Kuznetsov

About this article

Cite this article

Myalenko, V.I., Sankina, O.V. Selection of Geometric Parameters for Applying Strengthening Materials on the Friction Surface of Soil-Cutting Parts. J. Frict. Wear 43, 119–123 (2022). https://doi.org/10.3103/S106836662202009X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106836662202009X