Abstract

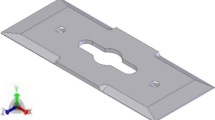

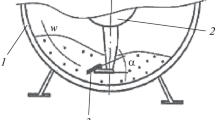

The sugarcane agroindustry covers 10,184,340 ha of arable land in Brazil. Harvesting this crop requires increasingly sophisticated equipment and sugarcane uses a basal cutting system with knives. These knives deteriorate rapidly due to abrasion with silica in the soil, which makes hard coating feasible for these components. Hard coatings generally involve the addition of chromium to increase the service life of agricultural machinery parts. The need to reduce the levels of chemical elements harmful to humans and animals in agricultural soils requires a study of alternatives to substitute chromium in hard metal alloys. Based on that, this work is aimed to investigate an alternative this respect; the present study proposes a change in coating from tungsten carbide paste (WC), which contains chromium, to a titanium carbide–based coating without chromium. To this end, FCAW (flux-cored arc welding) welding process was used, with self-shielding flux-cored wire containing alloy elements that increase resistance to abrasion, thereby extending the service life of the component. Simultaneous optimization of multiple responses was used to determine proposed welding parameters. For validation purposes, abrasion wear tests with a rubber wheel and dry sand were conducted to compare resistance to abrasion between the proposed material and that used in commercial knives. Results from accelerated wear tests showed FCAW higher performance (around 48%) compared to the WC coating. This demonstrates technical feasibility of the proposed hard metal deposition process using FCAW welding aimed to increase the service life of basal cutting knives without chromium.

Similar content being viewed by others

References

UNICA. URL http://www.unica.com.br/mapa-da-producao. Accessed 28 June 2018

da Silva EP, da Silva FM, Magalhães RR (2014) Application of finite elements method for structural analysis in a coffee harvester. Engineering 6(03):250 138

Voltarelli MA, Cassia MT, da Silva RP, Zerbto C, Com- Pagnon AM (2014) Corte sem danos, Revista Cultivar 137. https://www.grupocultivar.com.br/acervo/440. Accessed 28 June 2018

Lima AC, Ferraresi VA (2010) An´alise da resistência ao desgaste de revestimento duro aplicado por soldagem em facas picadoras de cana-de-açucar. Soldagem e Inspeçãoao São Paulo 15(2):94–102

Wei J et al (2017) Enhanced performance of light-controlled conductive switching in hybrid cuprous oxide/reduced graphene oxide (Cu 2 O/rGO) nanocomposites. Opt Lett 42.5:911–914

Silva EPD (2018) Avaliação comparativa dos processos de soldagem GMAW convencional e GMAW-STT R em aço inoxidavel duplex UNS S32205

Júnior F, Gedael J, Bracarense AQ (2019) ”Effects of metallic tape thickness on weld metal using titanium chips as flow components in tubular wires for TiC formation” Soldagem Inspeção 24

Rusteiko AC, Angelo JD, del Conte EGD (2019) Residual stress in metal arc additive manufacturing of mill knives cutting edges. Int J Adv Manuf Technol 104(9-12):4457–4464

Tóth G, Hermann T, Da Silva M, Montanarella L (2016) Heavy metals in agriculturalsoils of the European union with implications for food safety. Environ Int 88:299–209

Stempflé P, Domatti A, Dang HA, Takadoum J (2015) Mechanical and chemical wear components in environmental multi-asperity nanotribology. Tribology International 82:358–374

Dehghanghadikolaei A, Fotovvati B (2019) Coating techniques for functional en- hancement of metal implants for bone replacement: a review. Materials 12(11):1795

Yongqiang W, Xiaoya Z, Zhiqiang J, Xiubo T (2018) Characterization and mechanical properties of TiN/TiAlN multilayer coatings with different modulation periods. Int J Adv Manuf Technol 96(5-8):1677–1683

Jeong SH (2010) Thin zinc oxide and cuprous oxide films for photovoltaic applications

Lima AC, Valtair AF (2010) Analysis of wear resistance of hard coating applied by welding on sugar cane chopping knives. Weld Inspect 15.2:94–102

American Society for Testing and Materials, West Conshohocken, Pennsylvania, USA, ASTM 65-16 Standard Test Method for Measuring Abrasion Using the Dry Sand / Rubber Wheel Apparatus (May 2016). 14p

Hutchings I, Shipway P (2017) Tribology: friction and wear of engineering materials, Butterworth-Heinemann

Scotti A, Rosa LAA (1997) Influence of oscillation parameters on crack formation in automatic Fe b hardfacing. J Mater Process Technol 65(1-3):272–280

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Costa, A.L.G., Magalhães, R.R., Silva, E.P. et al. Technical feasibility of hard coating by flux-cored arc welding on a sugarcane cutting knife. Int J Adv Manuf Technol 111, 999–1013 (2020). https://doi.org/10.1007/s00170-020-06154-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06154-4