Abstract

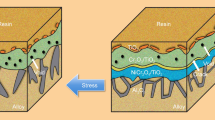

New-generation superalloys based on Ni intermetallics possess high thermomechanical stability at high temperatures and are widely used in modern industry. The fabrication of such materials by self-propagating high-temperature synthesis (SHS) is advantageous over traditional metallurgical technologies due to the use of the chemical-reaction energy. The development of coatings and pads based on the NiAl intermetallic on the surface of tungsten articles during SHS is of great practical interest. In this work, experiments on the interaction of the W substrate and the Ni–Al-based melt are performed in the SHS mode. When the W substrate connects with the NiAl intermetallic during SHS, the gradient welded joint 200–400 μm in thickness having a complex structure occurs. The Ni and Al melt is formed during the SHS reaction, and surface layers of the W substrate diffuse into it. The crystallization of the dendrites of the tungsten-based phase (84‒86 at % W and 16–14 at % Ni) and dendrites of the pseudobinary NiAl-based eutectic (β phase), in which precipitates of W-containing phase smaller than 50 nm in size and needle Ni3Al inclusions (γ') are present, occurs during cooling in the near-surface layer. The W + Ni + Ni3Al (α + γ + γ') containing the solid solution particles based on Ni3Al intermetallics of about 100 nm in size is revealed in the transient layer. The modification of the W substrate is modified with the formation of globular precipitations of W (α phase) in it, which considerably increases the surface area.

Similar content being viewed by others

REFERENCES

Jozwik, P., Polkowski, W., and Bojar, Z., Applications of Ni3Al based intermetallic alloys—current stage and potential perceptivities, Materials, 2015, vol. 8, pp. 2537–2568. doi 10.3390/ma8052537

Povarova, K.B., Bazyleva, O.A., Drozdov, A.A., Kazanskaya, N.K., Morozov, A.E., and Samsonova, M.A., Construction heat-resistant Ni3Al-based alloys: Fabrication, structure, and properties, Materialovedenie, 2011, no. 4, pp. 39–48.

Arginbaeva, E.G., Basyleva, O.A., and Turenko, E.I., Ni3Al-based intermetallic alloys, in: All Materials: Encyclopedic Handbook, 2012, no. 5.

Shu-Lan Liu, Chong-Yu Wang, and Tao Yu, Effect of Re and W upon brittle fracture in Ni3Al cracks by atomic simulation, Comput. Mater. Sci., 2015, vol. 110, pp. 261–269. doi 10.1016/j.commatsci.2015.08.037

Kolobov, Yu.R., Diffuzionno-kontroliruemye protsessy na granitsakh zeren i plastichnost’ metallicheskikh polikristallov (Diffusion-Controlled Processes on Grain Boundaries and Metallic Polycrystal Plasticity), Novosibirsk: Nauka, 1998.

Kolobov, Yu.R., Kablov, E.N., Kozlov, E.V., Koneva, N.A., Povarova, K.B., Graboveczkaya, G.P., Buntushkin, V.P., Basyleva, O.A., Muboyadjan, S.A., and Budinovskiy, S.A., Structura i svoistva intermetallidnykh materialov s nanofaznym uprochneniem (Structure and Properties of Nanophase Hardened Intermetallics Materials), Moscow: MISiS, 2008.

Takahashi, T. and Dunand, D.C., Nickel aluminide containing refractory-metal dispersoids. 2: Microstructure and properties, Mater. Sci. Eng. A, 1995, vols. 192–193, pp. 195–203. doi 10.1016/0921-5093(94)03235-1

Popovič, J., Brož, P., and Buršík, J., Microstructure and phase equilibria in the Ni–Al–W system, Intermetallics, 2008, vol. 16, no. 7, pp. 884–888. doi 10.1016/j.intermet.2008.04.003

Milenkovic, S., Schneider, A., and Frommeyer, G., Constitutional and microstructural investigation of the pseudo-binary NiAl–W system, Intermetallics, 2011, vol. 19, no. 3, pp. 342–349. doi 10.1016/j.intermet.2010.10.019

Hassel, A.W., Smith, A.J., and Milenkovic, S., Nanostructures from directionally solidified NiAl–W eutectic alloys, Electrochim. Acta, 2006, vol. 52, no. 4, pp. 1799–1804. doi 10.1016/j.electacta.2005.12.061

Cimalla, V., Röhlig, C.C., Pezoldt, J., Niebelschütz, M., Ambacher, O., Brückner, K., Hein, M., Weber, J., Milenkovic, S., Smith, A.J., and Hassel, A.W., Nanomechanics of single crystalline tungsten nanowires, J. Nanomater., 2008, vol. 2008. Article ID 638947. doi 10.1155/2008/638947

Milenkovic, S., Drensler, S., and Hassel, A.W., A novel concept for the preparation of alloy nanowires, Phys. Status Solidi A, 2011, vol. 208, no. 6, pp. 1259–1264. doi 10.1002/pssa.201000968

Lyakishev, N.P., Diagrammy sostoyaniya dvoinykh metallicheskikh system (Phase Diagrams of Binary Metallic Systems), Moscow: Mashinostroenie, 1996, vol. 1, pp. 183–185.

Franke, P. and Neuschutz, D, Ni–W, in: Binary Systems. Pt 4: Binary Systems from Mn–Mo to Y–Zr. Landolt-Börnstein—Group IV Physical Chemistry, 2006. Book DOI: doi 10.1007/b76778. Chapter doi 10.1007/10757285_38.10.1007/b76778

Kornienko, K., Kublii, V., Fabrichnaya, O., and Bochvar, N., Al–Ni–W (aluminium–nickel–tungsten), in: Light Metal Systems. Pt. 3. Landolt-Börnstein—Group IV Physical Chemistry, 2005. Book doi 10.1007/b96194. Chapter doi 10.1007/10915998_34.10.1007/b96194

Sytschev, A.E., Vrel, D., Kolobov, Yu.R., Kovalev, D.Yu., Golosov, E.V., Shchukin, A.S., and Vadchenko, S.G., Combustion synthesis in the Ni-Al-W system: Some structural features, Int. J. SHS, 2013, vol. 22, no. 2, pp. 110–113. doi 10.3103/S1061386213030118

Sytschev, A.E., Vrel, D., Kolobov, Yu.R., Kovalev, I.D., Golosov, E.V., Shchukin, A.S., and Vadchenko, S.G., Features of structure and phase formation in the Ni–Al–W system during self-propagating high-temperature synthesis, Kompoz. Nanostrukt., 2013, no. 2, pp. 51–58.

Itin, V.I. and Naiborodenko, Yu.S., Vysokotemperaturnyi sintez intermetallicheskikh soedinenii (High-Temperature Synthesis of Intermetallic Compounds), Tomsk: Tomsk. Univ., 1989, p. 34.

Novikova, M.B. and Budberg, P.B., Phase state of cast alloys of the Ni–NiAl–W system, Metally, 1986, no. 4, pp. 104–108.

Basyleva, O.A., Turenko, E.Yu., and Shestakov, A.V., Influence of heat treatment on the microstructure and mechanical properties of NiAl-based intermetallic alloy, Tr. VIAM, 2014, no. 9. doi 10.18577/2307-6046-2014-0-9-2-2

Brož, P., Buršík, J., and Stará, Z., Phase equilibria in the Ni–Al–W system at 900°C, Monatshefte für Chemie, 2005, vol. 136, no. 11, pp. 1915–1920. doi 10.1007/s00706-005-0391-y

ACKNOWLEDGMENTS

This study was supported by the Russian Foundation for Basic Research, project no. 1638-00246 mol_a.

Equipment of the Distributed Joint Usage Center at the Institute of Structural Macrokinetics, Russian Academy of Sciences, was used to perform the investigations.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by N. Korovin

About this article

Cite this article

Shchukin, A.S., Vadchenko, S.G. & Sytschev, A.E. Features of Microstructure Formation in the Ni–Al–W System during SHS. Russ. J. Non-ferrous Metals 59, 583–588 (2018). https://doi.org/10.3103/S1067821218050164

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218050164