Abstract

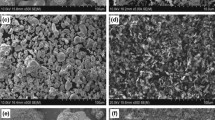

The possibility of using binders of the Next100 type alloyed with nickel and modified with WC, ZrO2, and hBN nanoparticles for fabricating a cutting tool based on superhard materials and intended for steel and cast iron machining is shown. It is established that alloying the binder with nickel makes it possible to increase its impact viscosity by a factor of 2.5 and substantially improve the resistance of tool segments during operation. An increase in binder strength by 100–150 MPa and hardness by 5–7 HRB is provided due to the introduction of WC, ZrO2, and hBN into it. The adhesion of cubic boron nitride to a binder increases in the presence of WC nanoparticles. The optimal ratio of diamond single crystals and cubic boron nitride in a working layer, at which maximal service characteristics of the tool are attained, is determined to be 75: 25. The formation of nanoclusters of amorphous boron at the interface of cubic boron nitride and a binder and dissolution of a small amount of nitrogen in binder components during hot compaction are revealed.

Similar content being viewed by others

References

Sung, C.-M., Brazed diamond grid: a revolutionary design for diamond saws, Diamond Relat. Mater., 1999, vol. 8, nos. 8–9, pp. 1540–1543.

Konstanty, J., Powder Metallurgy Diamond Tools, Oxford: Elsevier, 2005.

Bakori, A. and Szymariski, A., Practical Uses of Diamond, Warsaw: Ellis Horwood & Polish Scientific, 1993.

Sato, K., Yokoyama, T., and Suzuki, K., Production of electrodeposited diamond wheels and grinding performance for hard metals and ceramics, J. Mater. Process. Technol., 1996, vol. 62, pp. 303–308.

Li, Y., Li, G., Jiang, H., and He, Y., New type of matrix material for the manufacture of electroplated diamond tools, Ind. Diamond Rev., 2002, vol. 62, pp. 259–262.

De Resende, L.W., Corat, E.J., Trava-Airoldi, V.J., and Leite, N.F., Multi-layer structure for chemical vapor deposition diamond on electroplated diamond tools, Diamond Relat. Mater., 2001, vol. 10, pp. 332–336.

Denkena, B., Köhler, J., and Ermisch, A., Wire cutting tool concepts for steel machining, Adv. Mat. Res., 2011, vol. 325, pp. 238–243.

Tönshoff, H.K. and Hillmann-Apmann, H., Diamond tools for wire sawing metal components, Diamond Relat. Mater., 2002, vol. 11, nos. 3–6, pp. 742–748.

Köhler, J., Ermisch, A., and Denkena, B., Tool concepts for wire cutting of reinforced concrete, in: 1st Int. Conf. on Stone and Concrete Machining, Hannover, 2011, p. 6.

Amaral, P.M., Coelho, A., Anjinho, C.A., Fernandes, J.C., and Rosa, L.G., Evaluation of the relationship between diamond tool wear performance and the mechanical properties of the individual metallic binders, Adv. Mater. Forum, 2010, vols. 636–637, pp. 1467–1474.

Konovalov, V.A., Aleksandrov, V.A., and Levin, M.D., Influence of the strength of diamond containment and the rate of abrasive wear of a binder on the serviceability of a diamond-abrasive stone-cutting tool, Sintetich. Almazy, 1975, pp. 26–28.

Bogatyreva, G.P., Nevstruev, G.F., Il’nitskaya, G.D., Konovalov, V.A., and Tkach, V.N., The possibilities for improvement of the strength of diamond grit retention in a binder, Sverkhtverd. Mater., 2001, no. 2, pp. 20–25.

Loginov, P.A., Levashov, E.A., Kurbatkina, V.V., Zaitsev, A.A., and Sidorenko, D.A., Evolution of the microstructure of Cu—Fe—Co–Ni powder mixtures upon mechanical alloying, Powder Technol., 2015, vol. 276, pp. 166–174.

Tokova, L.V., Zaitsev, A.A., Kurbatkina, V.V., Levashov, E.A., Sidorenko, D.A., and Andreev, V.A., The features of influence of ZrO2 and WCnanodispersed additives on the properties of metal matrix composite, Russ. J. Non-Ferrous Met., 2014, vol. 55, no. 2, pp. 186–190.

Sidorenko, D.A., Zaitsev, A.A., Kirichenko, A.N., Levashov, E.A., Kurbatkina, V.V., Loginov, P.A., Rupasov, S.I., and Andreev, V.A., Interaction of diamond grains with nanosized alloying agents in metalmatrix composites as studied by Raman spectroscopy, Diamond Relat. Mater., 2013, vol. 38, pp. 59–62.

Sidorenko, D.A., Zaitsev, A.A., Kirichenko, A.N., Kurbatkina, V.V., and Levashov, E.A., Sevast’yanov, P.I., and Rupasov, S.I., Modification of the Fe—Cu–Co–Sn–P metal matrix with various forms of carbon nanomaterials, Russ. J. Non-Ferrous Met., 2015, vol. 55, no. 6, pp. 639–644.

Zaitsev, A.A., Sidorenko, D.A., Levashov, E.A., Kurbatkina, V.V., Rupasov, S.I., Andreev, V.A., and Sevast’yanov, P.V., Development and application of the Cu–Ni–Fe–Sn-based dispersion-hardened bond for butting tools of superhard materials, J. Superhard Mater., 2012, vol. 34, no. 4, pp. 270–280.

Monteiro, S.N., Skury, A.L.D., de Azevedo, M.G., and Bobrovnitchii, G.S., Cubic boron nitride competing with diamond as a superhard engineering material— an overview, J. Mater. Res. Technol., 2013, vol. 2, no. 1, pp. 68–74.

Song, Y., Nezu, K., Park, C.-H., and Moriwaki, T., Tool wear control in single-crystal diamond cutting of steel by using the ultra-intermittent cutting method, Int. J. Mach. Tools Manuf., 2009, vol. 49, nos. 3–4, pp. 339–343.

Lane, B.M., Shi, M., Dow, T.A., and Scattergood, R., Diamond tool wear when machining Al6061 and 1215 steel, Wear, 2010, vol. 268, nos. 11–12, pp. 1434–1441.

Neo, K.S., Rahman, M., Li, X.P., Khoo, H.H., Sawa, M., and Maeda, Y., Performance evaluation of pure CBN tools for machining of steel, J. Mater. Process. Technol., 2003, vol. 140, nos. 1–3, pp. 326–331.

Zaitsev, A.A., Sidorenko, D.A., Levashov, E.A., Kurbatkina, V.V., Andreev, V.A., and Rupasov, S.I., and Sevast’yanov P.V., Diamond tools in metal bonds dispersion-strengthened with nanosized particles for cutting highly reinforced concrete, J. Superhard Mater., 2010, vol. 32, no. 6, pp. 423–431.

Loginov, P., Mishnaevsky, Jr.L., Levashov, E., and Petrzhik, M., Diamond and cBN hybrid and nanomodified cutting tools with enhanced performance: Development, testing and modeling, Mater. Des., 2015, vol. 88, pp. 310–319.

Tillmann, W., Ferreira, M., Steffen, A., Ruster, K., Moller, J., Bieder, S., Paulus, M., and Tolan, M., Carbon reactivity of binder metals in diamond-metal composites— characterization by scanning electron microscopy and X-ray diffraction, Diamond Relat. Mater., 2013, vol. 38, pp. 118–123.

De Oliveira, L.J., Cabral, S.C., and Filgueira, M., Study hot pressed Fe-diamond composites graphitization, Int. J. Refract. Met. Hard Mater., 2012, vol. 35, pp. 228–234.

Werninghaus, T., Hahn, J., Richter, F., and Zahn, D.R.T., Raman spectroscopy investigation of size effects in cubic boron nitride, Appl. Phys. Lett., 1997, vol. 70, pp. 958–960.

Sachdev, H., Influence of impurities on the morphology and Raman spectra of cubic boron nitride, Diamond Relat. Mater., 2003, vol. 12, no. 8, pp. 1275–1286.

Kutsay, O., Yan, C., Chong, Y.M., Ye, Q., Bello, I., Zhang, W.J., Zapien, J.A., Zhou, Z.F., Li, Y.K., Garashchenko, V., Gontar, A.G., Novikov, N.V., and Lee, S.T., Studying cubic boron nitride by Raman and infrared spectroscopies, Diamond Relat. Mater., 2010, vol. 19, nos. 7–9, pp. 968–971.

Mermoux, M., Jomard, F., Tavares, C., Omnes, F., and Bustarret, E., Raman characterization of boron-doped {111} homoepitaxial diamond layers, Diamond Relat. Mater., 2006, vol. 15, nos. 4–8, pp. 572–576.

Panov, V.S. and Chuvilin, A.M., Tekhnologiya i svoistva spechennykh tverdykh splavov i izdelii iz nikh (Technology and Properties of Sintered Hard Alloys and Their Products), Moscow: MISIS, 2001.

Itoh, H., Matsudaira, T., Naka, S., Hamamoto, H., and Obayashi, M., Formation process of tungsten borides by solid state reaction between tungsten and amorphous boron, J. Mater. Sci., 1987, vol. 22, pp. 2811–2815.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © P.A. Loginov, D.A. Sidorenko, E.A. Levashov, V.A. Andreev, 2017, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Poroshkovaya Metallurgiya i Funktsional’nye Pokrytiya, 2017, No. 1, pp. 64–75.

About this article

Cite this article

Loginov, P.A., Sidorenko, D.A., Levashov, E.A. et al. Development of a Next Generation of Diamond Tools Based on Superhard Materials with a Nanomodified Binder for Steel and Cast Iron Machining. Russ. J. Non-ferrous Metals 59, 341–351 (2018). https://doi.org/10.3103/S1067821218030094

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821218030094