Abstract

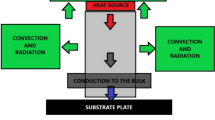

Technical and process features of a flowsheet for fabricating the wire of casting aluminum alloys intended to solder waveguides with the use of the combined continuous casting–pressing of nonferrous metals are considered. The dependences necessary and sufficient to design the constructive elements of equipment and process modes providing the implementation of conditions for the stable run of processes of continuous supply of the metal melt into the stream of the carousel molding laboratory machine, its solidification, and extrusion into the die opening similarly to Conform technology are established. The magnitude of the cross section of the hole in the supply dispenser of the metal melt into the stream of the crystallizer wheel is calculated. The process modes of the continuous casting–pressing using a laboratory installation of a billet 3 mm in diameter and its subsequent treatment by high-quality rolling and drawing in combination with intermediate annealing procedures to the final sizes are presented. According to this flowsheet, a pilot batch of round and square wire of alloys AK12Ts10 and AK12Ts15 has been produced in the amount of 3 kg and delivered to the AO ISS enterprise for industrial test soldering of waveguides.

Similar content being viewed by others

References

Bauzer, M., Zauer, G., and Zigert, K., Pressovanie: Spravochnoe rukovodstvo (Pressing: Reference Book), Trans. from German, V.L. Berezhnoi, Ed., ALYUMSIL MViT, 2009.

Perlin, I.L. and Raitbarg, L.Kh., Teoriya pressovaniya metallov (Theory of Metal Extrusion), Moscow: Metallurgiya, 1975.

Ermanok, M.Z., Feigin, V.I., and Sukhorukov, N.A., Pressovanie profilei iz alyuminievykh splavov (Extrusion of Profiles from Aluminum Alloys), Moscow: Metallurgiya, 1977.

Gulyaev, B.B.,Sintez splavov. (Osnovnye printsipy. Vybor komponentov) (Synthesis of Alloys. (Basic Principles. Choice of Components)), Moscow: Metallurgiya, 1984.

Gulyaev, B.B., Petrov, S.M., Petrova, S.G., and Abramova, A.A., Sintez vysokoprochnykh siluminov (Synthesis of High-Strength Silumins), Leningrad: Leningr. Gos. Univ., 1978.

Zhou, T.G., Jiang, Z.Y., Wen, J.L., Li, H., and Tieu, A.K., Semi-solid continuous casting-extrusion of AA6201 feed rods, Mater. Sci. Eng., 2012, vol. 8, pp. 108–114.

Guan, R.G., Wang, S.C., Wen, J.L., and Liu, X.H., Continuous semisolid extending extrusion process for producing AA2017 aluminium alloy flat bar, Mater. Sci. Technol., 2006, vol. 22, no. 6, pp. 706–712.

Sidel’nikov, S.B., Dovzhenko, N.N., and Katareva, A.A., Simulation of the combined process of continuous casting and rolling-pressing, Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2004, no. 5, pp. 34–39.

Sidel’nikov, S.B., Dovzhenko, N.N., and Zagirov, N.N., Kombinirovannye i sovmeshchennye metody obrabotki tsvetnykh metallov i splavov (Combined and Integrated Processing Methods of Nonferrous Metals and Alloys), Moscow: MAKS, 2005.

Valiev, R.Z., Murashkin, M.Y., and Sabirov, I., A nanostructural design to produce high-strength al alloys with enhanced electrical conductivity, Scr. Mater., 2014, vol. 76, pp. 13–16.

Raab, G.I., Raab, A.G., and Shibakov, V.G., Analysis of shear deformation scheme efficiency in plastic structure formation processes, Metalurgiya, 2015, vol. 54, no. 2, pp. 423–425.

Semenova, I.P., Polyakov, A.V., Raab, G.I., Lowe, T.C., and Valiev, R.Z., Enhanced fatigue properties of ultrafine-grained Ti rods processed by ECAP-Conform, J. Mater. Sci., 2012, vol. 47, no. 22, pp. 7777–7781.

Sherkunov, V.G., Gorokhov, Yu.V., Konstantinov, I.L., Ivanov, E.V., and Katryuk, V.P., Using the Conform method for processing of aluminum alloy turnings, Izv. Vyssh. Uchebn. Zaved., Tsvetn. Metall., 2015, no. 3, pp. 60–63.

Gorokhov, Yu.V., Sherkunov, V.G., Dovzhenko, N.N., Belyaev, S.V., and Dovzhenko, I.N., Osnovy proektirovaniya protsessov nepreryvnogo pressovaniya metallov (Fundamentals of Designing of Continuous Extrusion Processes of Metals), Krasnoyarsk: Sib. Fed. Univ., 2013.

Belyaev, S.V., Gorokhov, Yu.V., Gubanov, I.Yu., Bogdanov, D.V., Uskov, I.V., Uskov, D.I., Krokhin, A.Yu., Frolov, V.F., Mochalin, I.V., Kostin, I.V., Khramtsov, P.A., and Kosovich, A.A., Patent RF155319, 2015.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Yu.V. Gorokhov, S.V. Belyaev, I.V. Uskov, I.L. Konstantinov, I.Yu. Gubanov, T.Yu. Gorokhova, P.A. Hramtsov, 2016, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Tsvetnaya Metallurgiya, 2016, No. 6, pp. 65–70.

About this article

Cite this article

Gorokhov, Y.V., Belyaev, S.V., Uskov, I.V. et al. Application of combined casting–pressing for the fabrication of aluminum wire for soldering waveguides. Russ. J. Non-ferrous Metals 58, 75–79 (2017). https://doi.org/10.3103/S1067821217010059

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821217010059